Whether a subpanel in a detached garage needs a ground rod is a common question for homeowners and electricians. The short answer is yes, a subpanel in a detached garage does need its own ground rod for safety purposes. However, there are some nuances to the requirements that are important to understand.

Page Contents

- 1 What is a Subpanel?

- 2 Purpose of Grounding and Bonding

- 3 Grounding Requirements for Subpanels

- 4 Purpose of a Ground Rod

- 5 Proper Installation of a Ground Rod

- 6 Other Grounding Electrodes for Subpanels

- 7 Subpanel Grounding Diagram

- 8 Can You Share a Ground Rod?

- 9 What if There Already Exists a Ground Rod?

- 10 Are Multiple Ground Rods Better?

- 11 Does Distance to the Main Panel Matter?

- 12 Can a Subpanel Share the Water Pipe Ground?

- 13 Subpanel Grounding and GFCIs

- 14 Do Local Codes Change the Requirements?

- 15 Conclusion

What is a Subpanel?

A subpanel is a supplementary electrical panel that branches off from the main service panel. Subpanels are often installed in detached garages, workshops, pool houses, or other external buildings that need power but are located far from the main panel in the home. The subpanel connects to the main service panel and allows for additional circuits to be added for the detached structure.

Purpose of Grounding and Bonding

Grounding and bonding are critical safety components of any electrical system. They provide a safe path for electricity to follow in the event of a short circuit or electrical malfunction. This helps prevent electric shocks and electrocution hazards.

Specifically:

- Grounding refers to connecting equipment like subpanels, appliances, and conduits to the earth via ground rods, metal water pipes, or other means.

- Bonding refers to interconnecting all grounded metal parts in an electrical system so they are at the same voltage potential.

Grounding and bonding work together to shunt electricity safely away from equipment and people in hazardous scenarios. Proper implementation is required by the National Electrical Code (NEC).

Grounding Requirements for Subpanels

According to the NEC, all subpanels must meet several grounding and bonding requirements:

- The subpanel must be bonded to the main service panel.

- The subpanel must have an equipment grounding conductor running back to the main panel.

- The subpanel must have its own grounding electrode system separate from the main panel.

This third requirement is what necessitates a ground rod (or other grounding electrode) for a detached garage subpanel. Its purpose is to create an effective grounding means that is located close to the subpanel.

Purpose of a Ground Rod

A ground rod (also called a grounding electrode) provides a dedicated grounding point near the subpanel. It allows electricity to dissipate into the earth quickly. This is important because the grounding system must rapidly detect and clear any dangerous electrical faults that occur.

A ground rod has low impedance, meaning electricity can flow into it easily. And because it is buried, the moist soil aids conductivity. These factors enable the ground rod to disperse electricity into the earth without creating hazards.

Proper Installation of a Ground Rod

Installing a proper ground rod for a subpanel requires the following:

- Use a ground rod made of copper-clad or galvanized steel that is at least 8 feet long and 5/8 inches thick.

- Drive the rod vertically at least 8 feet into the ground, until only a few inches remain above the surface.

- Ensure the ground rod is within 6 to 8 feet from the exterior subpanel wall.

- Connect a ground wire from the subpanel equipment grounding bus to the ground rod.

- Clamp the wire securely to the ground rod above ground level.

In some cases, more than one ground rod may be needed, such as when rock prevents driving the rod fully into the earth. The key is ensuring a stable connection with the proper resistance to ground (25 ohms or less).

Other Grounding Electrodes for Subpanels

In some situations, the NEC allows the use of different grounding electrodes for a subpanel instead of (or in addition to) a standard ground rod:

- Concrete-Encased Grounding Electrode: Using a piece of rebar or bare copper wire embedded within a concrete foundation or footing that supports the garage.

- Ground Ring: A ring of bare copper wire buried around the external walls of a structure.

- Metal Underground Water Pipe: Using a buried metal water line supplying the building.

- Metal Frame of a Building or Structure: Where local codes allow, the metal frame of a garage can be used.

However, a ground rod is the most commonly used grounding electrode for a detached garage subpanel due to its simplicity.

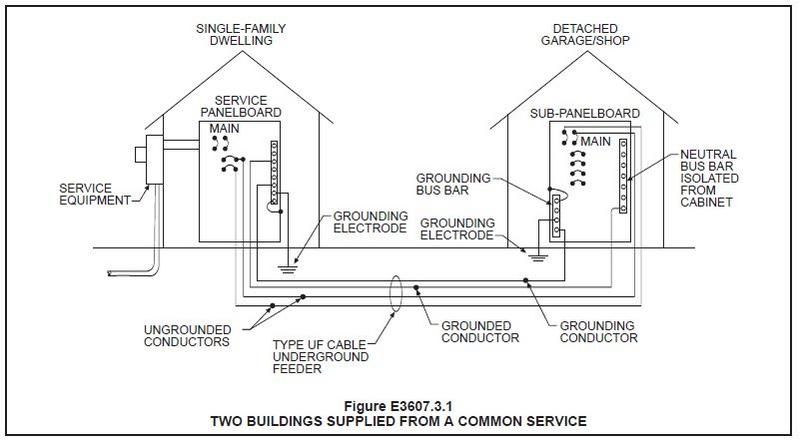

Subpanel Grounding Diagram

Here is a basic diagram showing proper grounding and bonding of a detached garage subpanel with a ground rod:

| Main Panel (House) | Subpanel (Garage) |

|---|---|

| Main bonding jumper connects neutral bus and ground bus in main panel | Subpanel bonding jumper connects neutral bus and ground bus in subpanel |

| GEC wire connects main panel ground bus to main ground rod | GEC wire connects subpanel ground bus to subpanel ground rod |

| Feeder neutral connects main neutral bus to subpanel neutral bus | |

| Feeder equipment grounding conductor connects main ground bus to subpanel ground bus |

This diagram shows how the grounded (neutral) and grounding systems are interconnected while keeping separate ground rods at both panels.

Because a subpanel is required to have its own “separately derived” grounding system, it cannot share the same ground rod as the main panel. The two must remain isolated. Sharing a ground rod between the main and subpanel would violate NEC regulations.

What if There Already Exists a Ground Rod?

Sometimes a previously existing detached garage or outbuilding may already have an established ground rod. If so, the subpanel can utilize this ground rod, provided it meets code requirements. There is no need to add a second ground rod for the subpanel in this case.

Are Multiple Ground Rods Better?

A single ground rod adequately grounds most residential subpanels. However, multiple ground rods can provide enhanced grounding capabilities in some cases. Installing a second ground rod may be warranted if soil conditions are poor or the building is large. The purpose is to achieve a ground resistance of 25 ohms or less.

The NEC requires that ground rods be spaced at least 6 feet apart if multiple rods are used. They must be bonded together with a ground wire to create a unified grounding system.

Does Distance to the Main Panel Matter?

The distance between the main panel and subpanel does not change the grounding requirements. Even if the garage is directly attached to the home, a separate ground rod (or other electrode) is still required at the subpanel. This maintains isolation of the grounding systems.

A subpanel is permitted to use the metal underground water pipe entering a detached garage as a grounding electrode instead of (or supplemental to) a ground rod. However, the main service panel grounding conductor cannot be connected to this water pipe ground. Each panel must have its own separate connection to the water pipe. This preserves isolation.

Subpanel Grounding and GFCIs

Proper grounding of a subpanel also enables GFCI (ground fault circuit interrupter) outlets to function safely in the detached building. GFCIs provide essential shock protection by detecting ground faults. If the subpanel grounding system was improperly connected, GFCIs would not work correctly.

Do Local Codes Change the Requirements?

Local electrical codes are based on the NEC but may include additional or amended regulations. Check with local permitting agencies to ensure all grounding requirements are being met.

For example, some jurisdictions require using a concrete-encased electrode as the main grounding electrode for any new construction.

Conclusion

Grounding requirements for subpanels are stringent because faulty grounding can lead to fires, equipment damage, and shock hazards. While the NEC permits some design flexibility, a ground rod is most often required when installing a subpanel in a detached garage.

To summarize, a ground rod must be installed when adding a subpanel to an outbuilding unless:

- There is already an existing high-quality grounding electrode present

- Local codes allow alternative grounding methods

Following code standards for proper ground rod placement, sizing, bonding, and resistance measurements ensures people and equipment are safeguarded.