Rust on brake rotors can range from a minor nuisance to a serious safety concern, depending on the extent of the rust and how it affects braking performance. In mild cases, surface rust may simply create an annoying squeaking or scraping noise when braking. More extensive rust can actually degrade the structural integrity of the rotor and cause braking problems.

Page Contents

- 1 What causes brake rotors to rust?

- 2 Mild brake rotor rust

- 3 Severe brake rotor rust

- 4 Is surface rust always bad?

- 5 How to remove light rust from rotors

- 6 How to prevent brake rotor rust

- 7 When to replace rusted brake rotors

- 8 The safety impact of rusty brake rotors

- 9 When to resurface or replace rotors

- 10 Conclusion

What causes brake rotors to rust?

Brake rotors are made of iron, which readily forms iron oxide (rust) when exposed to moisture. The rotating action of the brakes also rubs off the protective coating on the rotors, exposing the raw iron. Some common causes of brake rotor rust include:

- Driving in wet conditions

- Extended periods of vehicle inactivity

- Road salts and winter weather

- Corrosive environmental conditions near oceans or roads treated with salt

Rust typically starts at the outer edge of the rotor surface and slowly creeps inward over time. Rotor hats, the inner portion of the rotor that mounts to the wheel hub, are also prone to rust.

Mild brake rotor rust

A lightly rusted rotor may have a reddish-orange tint on the friction surface. This mild surface corrosion is common, especially on older vehicles. Mild rust causes the following symptoms:

- Squeaking or scraping noises when braking

- Pulsing brake pedal

- Visible rust coloration on rotor edges

- Rough texture or grooves on rotor surface

Mild rust is mainly an annoyance and generally does not impair braking power. The scraping helps grind off rust buildup. However, the noise and vibration are signs that rotors may need replacement soon.

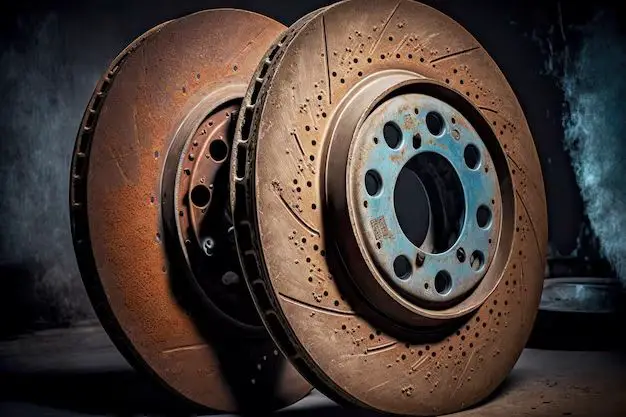

Severe brake rotor rust

Severely rusted rotors have heavy scaling, pitting, and grooves across the entire friction surface. Thick rust may also build up on the rotor hat and wheel mounting surface. Severe rust causes:

- Excessive brake pedal pulsation

- Longer stopping distances

- Uneven braking and pulling

- Scoring and damage to brake pads

- Complete loss of braking in extreme cases

Thick rust layers prevent the brake pads from smoothly compressing the rotor surface. The uneven contact results in vibration, grabbing, and uncontrolled changes in brake pad friction. This makes the vehicle unsafe to drive.

Is surface rust always bad?

Light surface rust does not automatically mean the rotors need replacement. As brake pads wear down, they effectively sand and scrape off minor rust on the rotor surface. If braking performance remains normal, light rust is not an immediate concern.

However, heavily rusted and pitted rotors must be replaced. The friction surface degrades to the point where sanding by the brake pads is insufficient. At this stage, rust-induced variations in rotor thickness also prevent smooth braking. Uneven, heavily corroded rotors can damage brake pads and caliper components.

How to remove light rust from rotors

Here are some DIY methods to remove mild rotor rust:

- Use 220-400 grit sandpaper to sand rotor surface. Always sand in direction of rotor rotation.

- Spray rotors with naval jelly or phosphoric acid. Let sit 5 minutes before rinsing.

- Apply rust remover gel. Let sit according to package directions. Rinse thoroughly.

- Use a wire brush attachment on a power drill to scrub rust. Wear eye protection.

- Sand rotors with an abrasive disc on a power drill.

Consider having severely rusted rotors turned on a brake lathe to resurface the friction surface. Turning removes up to 0.060 inches of metal. Turning is cheaper than replacement, but technicians won’t turn rotors below minimum thickness specifications.

How to prevent brake rotor rust

Here are some tips to slow rust formation on brake rotors:

- Drive regularly to avoid having brakes sit unused

- Wash away road salts, grime, and debris often

- Store vehicle in a clean, dry garage when possible

- Consider rustproofing in coastal climates

- Replace cracked dust shields that expose rotors

- Have brakes serviced regularly to prevent seized components

High-performance brake kits are also available with rotors coated in black zinc plating, powder coating, or paint to resist corrosion. Ceramic brake pads help reduce rotor wear and oxidation. But the friction from braking will gradually rub away any protective coatings over time.

When to replace rusted brake rotors

Rotor replacement is necessary if friction surfaces become deeply pitted, gouged, or cracked. Thickness variation between high and low spots should not exceed 0.001 inches. Have a mechanic inspect brake components if you notice any of these warning signs:

- Visible rust buildup on rotors and mounting surfaces

- Brake pedal pulsations, longer stopping distance

- High-pitched squealing when braking

- Steering wheel shudder when braking

- Uneven rotor wear identified via thickness measurements

- Rotors are worn below minimum thickness specifications

Waiting too long increases the risk of rotor failure and dangerous brake problems. Always replace rotors in axle sets to ensure balanced braking.

The safety impact of rusty brake rotors

Rust damages the friction surface and alters the thickness of brake rotors. Both effects reduce the brakes’ ability to safely slow and stop the vehicle.

Degraded friction surface

Pitting and grooves from rust prevent smooth contact between the brake pads and rotor. The inconsistent friction results in grabbing, uneven braking, and loss of overall stopping power.

Thickness variation

Thick rust layers create high and low spots along the rotor surface. These thickness variations cause brake pad judder, pulsation through the brake pedal, and steering wheel shakes when braking. Thickness must remain uniform within 0.001 inches for smooth braking.

Other safety risks

Severe rust corrosion can also:

- Cause rotor cracking or complete fracture

- Result in detachment of rust scaling that can jam brakes

- Lead to damaged brake pads, calipers, and other components

- Create annoying brake noise hazards for pedestrians

Rusted rotors reduce braking effectiveness and vehicle control, especially in wet conditions. Heavily corroded rotors should be replaced immediately to ensure safety.

When to resurface or replace rotors

| Rotor Condition | Solution |

|---|---|

| Surface rust only | Resurface |

| Pitting up to 1 mm deep | Resurface |

| Grooves up to 1.5 mm deep | Resurface |

| Cracks, damage beyond friction surface | Replace |

| Deep pitting, thickness variation > 1 mm | Replace |

| Out of thickness specification | Replace |

Rotors with minimal rust and wear can be resurfaced to refresh the braking surface. Heavily corroded and damaged rotors must be fully replaced. Seek professional diagnosis to determine if resurfacing can recover usable rotor thickness and smoothness.

Conclusion

Brake rotors are prone to rust over time from exposure to water, road salts, and high heat cycles. Minor surface corrosion causes annoying brake noises but does not significantly impact safety or performance. Severely rusted rotors with heavy pitting, grooving, cracking, or excessive thickness variation can lead to unpredictable braking behavior, longer stopping distances, and potential failure. Addressing rotor rust early provides the best chance for resurfacing or less costly repairs. Neglected rust damage ultimately requires full rotor replacement to restore safe braking.