A hand plane is a woodworking tool used to shape and smooth wood surfaces. To work properly, the blade of a hand plane needs to be very sharp. A dull blade will tear out wood fibers rather than slicing them cleanly, resulting in a rough surface. Sharpening a hand plane blade is a critical skill for any woodworker to master. There are several items you’ll need to properly sharpen a hand plane blade.

Page Contents

What is a Hand Plane?

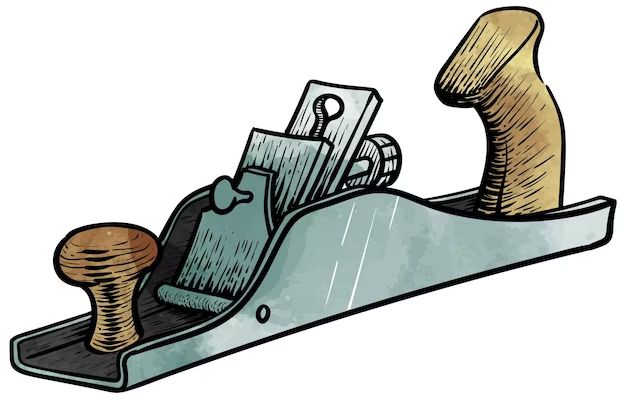

A hand plane is a tool that holds a steel blade at an adjustable angle against a sole plate. The sole plate sits flat on the surface of the wood as the blade removes shavings to flatten, taper, or smooth the wood. Bench planes and block planes are the most common types of hand planes. Bench planes have longer soles and blades for flattening and smoothing larger surfaces. Block planes are smaller for working edges and end grain. Specialty hand planes include shoulder planes for trimming tenons, rabbet planes for cutting rabbets and dados, and chisel planes for paring across the grain.

Why Sharpen a Hand Plane Blade?

Sharpening the blade is critical for proper hand plane function. A sharp blade slices through wood fibers cleanly. This allows very thin and consistent shavings to be taken off with each pass of the plane. Taking thin shavings is key to creating a smooth surface. In contrast, a dull blade will tear out wood fibers rather than slicing them. This creates rough, uneven surfaces and requires more force to push the plane. It also creates deeper grooves that require more passes to flatten out. Keeping your hand plane blades sharp is essential for efficient and precise woodworking.

Items Needed to Sharpen a Hand Plane Blade

Coarse Sharpening Stone

A coarse sharpening stone is used for establishing a new edge or repairing major damage and dullness. Coarse stones range from 60 to 400 grit. Lower grit numbers indicate coarser stones. Coarser stones cut metal more aggressively to reshape damaged edges. Common types of coarse stones include silicon carbide and aluminum oxide waterstones, oilstones, diamond stones, and sandpaper.

Fine Sharpening Stone

A fine sharpening stone is used for refining the edge after reshaping it with a coarse stone. Fine stones usually range from 800 to 2000 grit. The finer grit abrades less metal for a smoother polish. Finer stones include waterstones, oilstones, diamond stones, and sandpaper.

Flattening Stone

A flattening stone is needed to periodically flatten the surfaces of waterstones. Waterstones wear unevenly with use, developing grooves and hollows that will transfer to the blade edge. A flattening stone quickly grinds the waterstone surface back to flat. Diamond flattening stones work well for this task.

Honing Guide

A honing guide holds the plane blade at a consistent angle for sharpening. This ensures the bevel is sharpened evenly along its length. The blade is clamped in the guide, which often has registration marks for common bevel angles like 25° and 30°. High quality honing guides have a wheel system for precision blade registration.

Honing Compound

Honing compounds are used to polish a razor sharp edge after sharpening. These are extremely fine abrasives, usually in the 1 to 0.25 micron range. Honing compounds are rubbed onto a strop or directly onto a flat sharpening stone. This puts a mirror finish on the edge for a clean, sharp slicing action.

Stropping Compound

A strop loaded with stropping compound can also refine the edge to hair-popping sharpness. A leather and canvas strop is ideal for applying the compounds. The edge is drawn across the loaded strop using minimal pressure to polish and align the edge without removing metal. This also helps maintain the edge between sharpening sessions.

Micro Bevel Guide

A micro bevel guide assists in sharpening a tiny secondary bevel along the edge. This strengthens the thin edge to prevent rolling and burnishing in dense exotic woods. It also helps the edge last longer between sharpenings. A guide ensures the micro bevel is sharpened consistently along the length of the blade.

Magnifying Glass

A magnifying glass allows close inspection of the edge to analyze its sharpness. Look for a clean, contiguous edge without imperfections like chips or rounded areas. The sharpness can be checked by observing how the edge reflects light. A dull edge will reflect light in a wide band while a sharp edge creates a very fine, narrow line of reflection.

Leather Strop

A leather strop further hones the edge after sharpening with progressively finer abrasives. Stropping aligns and polishes the edge without grinding away more metal. Just the edge is burnished as its drawn across the leather with minimal pressure. A strop extends the life of the edge between sharpenings.

Sharpening Process

Here are the basic steps to sharpen a hand plane blade:

Step 1 – Lap the Back

The back of the blade must be flat for proper sharpening. A flattened back reference ensures the bevel is sharpened at the correct angle. Use a coarse diamond stone to remove any warping or wear until the back is flat. Lap the entire back surface. Polish the back to 600 grit to prepare it for sharpening.

Step 2 – Grind Damaged Edge

Reform the edge bevel if there are nicks or rounding using a coarse stone. Clamp the blade in a honing guide. Set the guide for your desired sharpening angle. A 30° angle is common for bench plane blades. Grind away damaged areas evenly across the length of the blade on the coarse stone to establish a straight bevel.

Step 3 – Refine the Bevel

Progress through finer stones to refine the edge bevel. Gradually step up from your coarse stone to at least an 8000 grit finishing stone. Apply sharpening oil or water per the stone. Maintain the same sharpening angle. Use sweeping, consistent strokes across the stones to create an even, polished bevel facet. Flip the blade and repeat sharpening on the opposite side of the bevel.

Step 4 – Hone the Edge

Hone the edge using a stropping motion with light pressure. Strop strokes should be diagonal or perpendicular to the bevel facets. Refine the edge on a fine stone using honing compounds. Then strop with honing or stropping compounds applied to a leather paddle. This polishes and aligns the edge for incredible sharpness. Use a magnifying glass to inspect the edge.

Step 5 – Add Micro Bevel (optional)

For added support, sharpen a micro bevel of 1-2° along the edge using a guide. Make alternating strokes on each side of the blade to form a very small secondary bevel. Polish the micro bevel. Then make a few final stropping strokes to align the edge. The micro bevel strengthens the edge while only minimally increasing cutting resistance.

Step 6 – Flattening Stone

Regularly flatten waterstones by grinding the surface on a flattening stone. This removes any uneven wear and grooves that will transfer to the blade. Flattening is needed whenever waterstones begin to cut unevenly. Always flatten them before fine sharpening.

Tips for Maintaining Sharpness

Here are some tips to extend the sharpness of your hand plane blades between sharpening sessions:

- Strop the edge frequently – Stropping realigns the edge without removing metal

- Store blades carefully – Wrap blades or store in protective sleeves

- Avoid metal-to-metal contact – Prevent nicks by not letting blades contact metal

- Sharpen early – Sharpen at the first signs of dullness rather than letting it progress

- Use a light touch – Reduce sharpening pressure as you progress through stones

- Clean regularly – Rinse sharpening stones and lap during use to remove swarf

- Inspect often – Check for flatness, warping, chips, rounding, etc.

- Protect the edge – Never put a plane down on its edge

Following a complete sharpening progression and using proper techniques will produce incredibly sharp, long-lasting edges on your hand plane blades. Maintaining that sharpness then becomes easier with preventative care. Investing some time to learn sharpening skills will greatly improve your hand tool experiences.

Conclusion

Maintaining sharp hand plane blades is essential for proper hand plane function and efficient woodworking. It requires a few key items – coarse and fine sharpening stones, a honing guide, stropping paddles and compounds, and a method to flatten waterstones. Combined with solid sharpening techniques for grinding, refining, and polishing, these items enable creating razor sharp edges on plane blades. Learning freehand sharpening without guides also develops useful skills. Sharp hand plane blades allow taking gossamer thin shavings to produce sheer, glass-smooth wood surfaces. The process of sharpening and using hand tools connects woodworkers closely with their materials and craft. Investing in sharpening supplies and skills pays off in handsome woodworking results.