A router and a jointer are two common woodworking tools that serve different purposes. A router is a versatile tool used to cut grooves, slots, edges, and decorative details into wood. It can be handheld or mounted in a router table. A jointer is a stationary machine used to flatten, straighten, and square up the edges and faces of boards. So while they are both woodworking tools, they have quite different functions.

The key question is whether a router has the capability to perform the tasks of a jointer. There are some aspects of jointing that a router may be able to accomplish, but there are also limitations that prevent a router from fully replacing a dedicated jointer. Evaluating the pros and cons can help shed light on whether using a router as makeshift jointer is a viable option.

Page Contents

Key Functions of a Jointer

To understand whether a router can substitute for a jointer, it helps to first review what a jointer does. The main functions of a jointer include:

- Flattening one face of a board – Jointers have a wide cutterhead that spans the width of the board to create an extremely flat surface as it passes over the cutterhead.

- Squaring one edge perfectly straight – The fence on a jointer ensures that one edge of the board is cut precisely straight and square relative to the flattened face.

- Preparing boards for gluing into wider panels – By flattening one face and squaring one edge, jointers prepare boards to be edge glued together while keeping the faces and edges aligned.

- Removing cupping or bowing – The cutting action of a jointer can remove cupping (curving across the width of a board) or bowing (curving along the length) to flatten boards.

- Beveling edges – Some jointers have the capability to tilt the fence to cut beveled edges.

These key functions allow jointers to transform rough lumber into boards ready for glue-up or final dimensioning. Having one flat face and one straight edge enables the rest of the milling process.

Capabilities of a Router

Now let’s look at what types of cuts and milling a router can perform:

- Trimming and chamfering edges – A router can cut decorative edges or ease sharp edges.

- Cutting grooves and dados – Routers excel at cutting channels, grooves, and slots across the face of boards.

- Producing edged profiles – With a rabbeting bit, a router can cut rabbets and steps along an edge.

- Cutting joinery – Routers can cut joinery like dovetails, box joints, and t-slots with the appropriate jig and bit.

- Decorative detailing – From roundovers to fluting to inlays, routers can add limitless decorative details.

- Trimming laminates – A flush trimming bit allows a router to trim countertop or board laminates perfectly flush.

Routers are designed to cut profiles and grooves across the width of a board. Although incredibly versatile, traditional handheld routers are more limited when it comes to prepping and flattening wide boards.

Attempting Jointer Functions with a Router

With creativity and careful technique, a router can somewhat mimic a jointer. But there are also clear limitations. Here are some key factors to consider:

Flattening Broad Surfaces

Jointers have an expansive cutterhead that can plane down wide boards in a single pass. Routers have a relatively narrow cutting width. To flatten a broad surface with a router, you need to make many passes side-by-side across the wood. Doing this precisely and without unevenness takes very careful technique. The smaller the router bit, the more passes required. It’s not impossible, but much more difficult than a jointer.

Squaring Edges

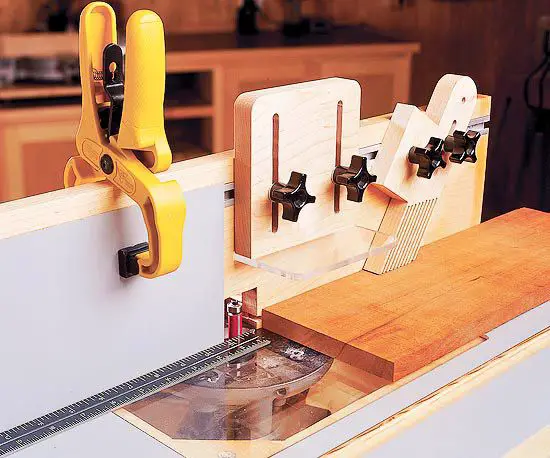

A jointer fence provides a continuous reference surface that guarantees a precisely straight edge at a perfect 90 degree angle. Trying to square an edge with a handheld router would involve placing some sort of guide and carefully moving the router along the length. This is hard to do as accurately as a jointer. A router table provides more support when trimming edges, but still doesn’t have the foolproof precision of a jointer fence.

Preparing Boards for Gluing

To glue up panels without gaps or steps between boards, the edges must be flat, straight, and square. Matching the cutterhead width of a jointer is nearly impossible with a router. A router could technically flatten and square each individual board, but doing so consistently and accurately would be extremely challenging.

Removing Cupping or Bowing

The cutting action of a jointer applies pressure across the width of a board to remove cupping or flattening. A router applies pressure primarily in a localized area. Removing significant cupping or bowing along the length of a board would be quite difficult without a jointer.

Beveling Edges

A jointer allows quick and precise angled bevels by tilting the fence. Beveling an edge with a router would require setting up an angled guide. Minor bevels would be possible but more complex than on a jointer.

Limitations in Stability and Precision

Even with a router table, routers lack the mass, stability, and precision of a stationary jointer. Making the precision cuts needed for jointing requires a tool that can be calibrated very accurately. The handheld nature and flexibility of routers make them inherently less capable in this regard.

Specialty Router Tools

There are some specialty router tools that can improve the ability to flatten and straighten boards:

- Router sleds – A sled keeps the router stable and rides along straight rails to flatten a surface.

- Rail guides – These guide rails allow a router to slide evenly along a straight edge.

- Router planing jigs – These hold the router at a consistent height to plane smooth a surface.

- Edge guide kits – These combine a track with stops to guide along edges for straight cuts.

These accessories can definitely improve a router’s capability for jointing tasks. However, they still generally fall short of a real jointer’s functions and precision. These jigs often have limited width capacity compared to a jointer. And adapting a router for jointing relies on a lot of setup.

Conclusion

At the end of the day, it’s very difficult to fully replicate the functions of a jointer using a router. While a router can achieve some of the end results of jointing – flattening and straightening boards – it lacks the purpose-built features that make a jointer precise and efficient. Adapting a handheld router requires complex setups. And using a router table still doesn’t provide the foolproof reference surfaces and width capacity on par with a jointer.

For small-scale projects, it may be possible to muscle through the milling process with just a router, getting boards pretty flat and straight. But for wider panels, furniture projects, and precise woodworking, a real jointer makes the process much more straightforward and accurate. Routers and jointers are best used together, each performing its specialized functions. With both tools in a shop, the two complement each other to streamline milling and preparation of lumber. But the unique capabilities of a jointer are difficult to fully replace with just a router alone.

Frequently Asked Questions

Can you use a router instead of a jointer?

It’s very difficult to fully replicate the functions of a jointer using only a router. A router lacks the wide cutterhead, reference fences, and stability to easily flatten and square boards. With specialty jigs, a router can achieve some basic jointing tasks for smaller boards. But for most serious woodworking, a dedicated jointer works much better.

What are the disadvantages of using a router as a jointer?

Disadvantages include:

- Narrow cutting width makes flattening wide surfaces time-consuming

- Hard to maintain flatness across full width of boards

- No continuous fence for ensuring a straight square edge

- Lacks mass and stability of a full-size jointer

- Requires complex setups with guides and jigs

- Difficult to achieve the precision of a jointer for glue-ups

Can you flatten boards with a router?

It is possible to flatten boards with a router using specialty sleds or flattening jigs, but it requires careful technique. The narrow cutterhead width makes it very time consuming for wider surfaces. Maintaining flatness across the full width is difficult without a reference fence. Some minor flattening is possible, but routers can’t match the ease and precision of a jointer for this task.

What can a router not do that a jointer can?

Key limitations of routers vs. jointers:

- Flattening wide boards in a single pass

- Producing a perfectly straight square edge along full length

- Reference fences for accuracy and precision

- Removing significant cupping or bowing

- Cutting precise bevels along an edge

Is it worth buying a jointer?

For any serious woodworking a jointer is a very worthwhile investment. Trying to prep lumber without one requires much more time and effort. The precise flattening, edge jointing, and squaring functions are extremely difficult to replicate without a jointer. Their wide cutterheads and reference surfaces enable accurate glue-ups and efficient processing of lumber. Once you use a real jointer, you’ll wonder how you ever worked without one.

Conclusion

In summary, routers lack the specialized features and precision to effectively perform full-scale jointing tasks. Small-scale flattening and straightening is possible with jigs and guides, but a router can’t fully replace a jointer. For serious woodworkers doing glue-ups and milling lumber, a real jointer is a near necessity. Routers are best utilized for what they specialize in – decorative cuts, joinery, trimming, and profiling. Relying solely on a router for jointing is an extremely difficult and frustrating practice. While a router can assist in some basic jointing, the capabilities of a full jointer are unmatched for any large-scale or precision work.