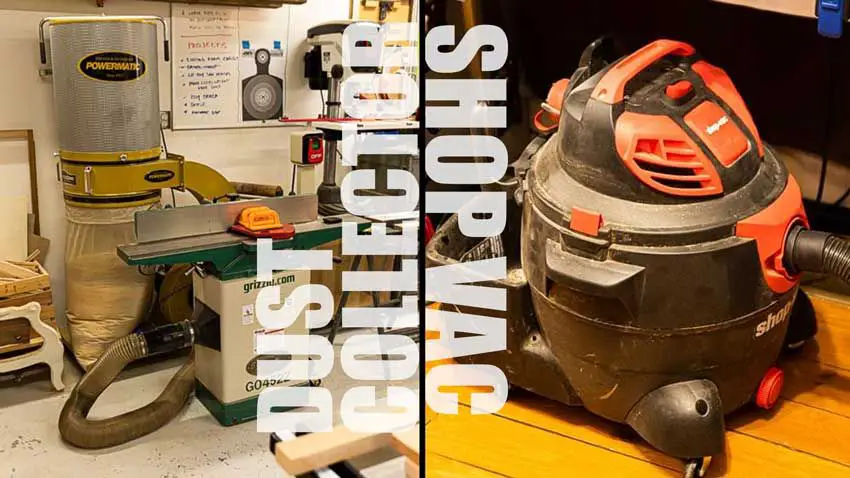

A shop vac can absolutely be used for dust collection. Shop vacs are powerful wet/dry vacuums that can provide strong suction for picking up dust and debris. With the right attachments and setup, a shop vac can be an effective tool for managing dust from woodworking, home improvement projects, or other messy hobbies.

Page Contents

- 1 What are the benefits of using a shop vac for dust collection?

- 2 What are some limitations of using a shop vac?

- 3 What type of dust collection setups can be made with a shop vac?

- 4 What type of filter should you use?

- 5 What accessories are useful for dust collection?

- 6 What are some setup tips for good dust collection?

- 7 What are good ways to deal with fine dust like sawdust?

- 8 What maintenance is required when using a shop vac for dust collection?

- 9 How do you clean filters in a shop vac?

- 10 What are signs of problems in a dust collection system?

- 11 How can airflow and suction be improved?

- 12 Should shop vacs automatically turn on/off?

- 13 Should a shop vac be used with fine concrete dust?

- 14 Conclusion

What are the benefits of using a shop vac for dust collection?

There are several benefits to using a shop vac for dust collection:

- Powerful suction – Shop vacs are designed to provide strong suction for cleaning up wet or dry messes. This makes them very effective for sucking up dust and fine particles.

- Large capacity – Shop vacs have large buckets/tanks, often 5 gallons or more. This provides good storage capacity for collecting dust without having to frequently stop and empty it.

- Versatile attachments – Shop vacs come with various hose, wand, nozzle and filter attachments that allow you to configure them for dust collection. Plastic tubes can connect power tools directly.

- Good filtration – Shop vacs use cartridge and/or bag filters that trap most fine dust particles, keeping them from blowing back into the air.

- Affordable price – Shop vacs are reasonably priced compared to dedicated dust collectors. Basic models start at around $50 while larger sizes go up to $200.

What are some limitations of using a shop vac?

While very useful for dust collection, shop vacs do have some limitations:

- Less suction power than dedicated collectors – Industrial dust collectors use more powerful suction motors better suited for fine particles.

- Smaller filter surface area – The filters may clog up faster than a dust collector when vacuuming very fine dust.

- Noisy – Shop vacs produce quite a bit of noise which may be annoying in a small workspace.

- Not automatically activated – You either have to manually turn it on/off or rig up an automatic switching system.

- Risk of fine dust leaking – If filters are not maintained properly, some fine particles may leak back into the air.

What type of dust collection setups can be made with a shop vac?

There are a variety of dust collection setups that can be created by connecting a shop vac:

- Direct connection to power tools – Use plastic hoses to connect the vacuum hose directly to a power tool like a sanding tool, router, circular saw, etc. This provides suction right at the source of dust.

- Collection buckets or small cyclone separators – Use a simple bucket or cyclone to collect dust right near the tool. The vacuum pulls dust into the separator which collects most of it, reducing the amount entering the vac.

- Make a mobile cart system – Mount the shop vac, hoses, accessories and collection bucket all on a rolling cart. This makes a portable dust collection system.

- Build a central collection system – Use PVC piping to run vacuum hoses from the shop vac to multiple work areas. Gates allow opening suction vents near tools as needed.

What type of filter should you use?

The filter used in the shop vac will impact dust collection performance. There are a few options:

- Standard cartridge filters – These are the common pleated filters that trap larger dust particles but very fine dust may pass through.

- Fine particle cartridge filters – Cartridges with a HEPA rating or ultra-fine filtration can capture smaller dust particles, down to 0.3 microns in size.

- Filter bags – Bags provide greater surface area than cartridges. Models with very fine pores trap most dust particles.

- Combination cartridge + filter bag – Using both a fine filter cartridge and bag provides multiple filtration stages for the best dust capture.

For very fine dust like sawdust, a true HEPA filter bag or combination method is recommended. This will help minimize fine particles blowing back into the air.

What accessories are useful for dust collection?

There are various shop vac accessories that come in handy for dust collection setups:

- Vacuum hoses – Long, flexible hoses allow you to move around a work area and reach tools easily. Get smooth interior hoses to avoid clogs.

- Wands and nozzles – Wands let you clean hard to reach areas. Crevice tools and brushes are great for vacuuming up dust piles.

- Hose fittings – Get adapters to securely connect hoses to power tools, gates, collection separators and other accessories.

- Reducers – Narrow the hose diameter when connecting to dust ports for better suction.

- Anti-static hoses – These prevent static charge buildup which attracts fine dust to hose walls rather than pulling it into the vac.

Also look at accessories like blast gates, reducers, separators and adapters made specifically for dust collection systems.

What are some setup tips for good dust collection?

Follow these tips when setting up your shop vac dust collection system:

- Use smooth interior hoses to avoid catching dust in ridges.

- Secure all connections with clamps or adapters to prevent air leaks.

- Use short, straight runs to minimize airflow restrictions.

- Keep bends and kinks out of the hose that reduce suction.

- Place collection bucket close to the vacuum with minimal hose in between.

- Keep filters clean and change when needed to maintain good airflow.

- Use gates to isolate suction to one tool at a time.

- Consider an automatic power switch to turn vacuum on/off when tools start.

What are good ways to deal with fine dust like sawdust?

Extra steps may be needed when vacuuming very fine dust like sawdust that can easily bypass filters and blow into the air:

- Use true HEPA filter bags or combination filters to capture ultra-fine particles.

- Add a pre-separator bucket or cyclone to collect most dust before it reaches the filter.

- Use smooth anti-static hoses to prevent dust clinging to hose walls.

- Keep all connections airtight so dust does not leak out.

- Connect vac hose directly to tool dust port when possible.

- Turn off tool and vac before disconnecting collection hose.

- Wear respirator mask so you don’t inhale remaining fine dust.

What maintenance is required when using a shop vac for dust collection?

Proper maintenance is key to maintaining good dust collection performance:

- Inspect filters frequently and replace when visibly dirty.

- Empty collection container often so it does not overfill.

- Clean interior hose walls if dust builds up and causes clogs.

- Check for and fix any air leaks in the system.

- Clean out any gates, blast valves or dust ports that accumulate buildup.

- Check condition of accessories and replace if damaged.

- Follow shop vac manufacturer maintenance recommendations.

Take time after each use to clean components and check for issues. Address any problems immediately to prevent dust collection effectiveness from degrading.

How do you clean filters in a shop vac?

Shop vac filters should be cleaned regularly as they accumulate dust. Follow these steps:

- Unplug shop vac and remove filter.

- Take filter outdoors and shake it or tap it gently to remove loose dust.

- If needed, use a low pressure air hose to blow dust out of pleats being careful not to damage the filter.

- Wash cotton bag filters in water and mild detergent then allow to fully dry.

- If filter is very dirty, consider replacing it with a new one for best results.

- Reinstall filter securely in vac making sure the seal is air tight.

Always check filters after cleaning to make sure they are not ripped or damaged. Replace right away if you see any tears or holes.

What are signs of problems in a dust collection system?

Watch for these signs of issues developing in your shop vac dust collection setup:

- Decrease in suction power at the dust collection port

- Dust leaking from connections or the shop vac itself

- Tools bogging down as if airflow is being restricted

- Hose clogging up frequently with dust

- Shop vac motor working harder with loud hum or whine

- Dust blowing out from vac exhaust when running

- Frequent overloading/clogging of the collection container

When you notice these warning signs, thoroughly inspect the system to identify the problem. Common causes are hose clogs, loose connections, damaged components or clogged up filters.

How can airflow and suction be improved?

If dust collection performance declines, try these tips to increase suction power and airflow:

- Clean or replace vacuum filters if they are restricting airflow.

- Use smooth hoses instead of ribbed hoses.

- Eliminate kinks, tight bends or length in hoses.

- Open dust collection gates fully when in use.

- Check blast gates for stuck closes or openings.

- Ensure fittings are air tight with no leakage or gaps.

- Remove collection buckets that are overfilled.

- Clear any blockages or buildup in hoses, pipes or dust ports.

Improving airflow delivers stronger suction to capture dust rather than it escaping into the air.

Should shop vacs automatically turn on/off?

An automatic power switch that turns the shop vac on and off in sync with your power tools can be very useful for dust collection. There are a couple options:

- Sound activated switch – This listens for tool noise and activates the vac. It turns the vac off after a delay when noise stops.

- Power sensing switch – This mounts to the tool’s power cord and detects current flow. It turns the vac on/off with the tool’s power.

An automatic switch means you don’t have to manually start the vac every time you use a tool. This encourages consistent and thorough dust collection.

Should a shop vac be used with fine concrete dust?

It’s best not to use a shop vac with very fine concrete dust or powders. The small particle size of materials like cement, grout and mortar can be problematic:

- The fine dust will quickly clog up filters.

- Abrasive nature can damage seals and shorten filter life.

- High alkalinity can degrade components and hoses.

- Super fine particles will blow through filters back into the air.

Wet slurry vacuums or equipment designed for concrete dust should be used. Trying to collect cement materials with a shop vac will likely damage the machine.

Conclusion

While a shop vac has limitations compared to true industrial dust collectors, it can be a very effective tool for managing dust from DIY projects and small hobby shops. With some adapters, hoses and basic accessories, you can create a customized dust collection system tailored to your specific power tools and workspace layout. Just be sure to use proper filtration and do regular maintenance to maximize performance and keep dust under control.