A water hammer arrestor is a plumbing device that is designed to absorb the shock waves that can occur when water supply lines are quickly turned off. This shock wave is also known as a water hammer. Installing a water hammer arrestor helps prevent damage to pipes and fixtures that can result from these shock waves.

Page Contents

- 1 What is a water hammer?

- 2 How do water hammer arrestors work?

- 3 Where should a water hammer arrestor be installed?

- 4 Does a water hammer arrestor’s orientation matter?

- 5 Installing a water hammer arrestor horizontally

- 6 Installing a water hammer arrestor vertically

- 7 Considerations when installing a water hammer arrestor

- 8 Conclusion

What is a water hammer?

A water hammer occurs when a valve in the plumbing system suddenly closes, either from someone turning off a faucet or an automatic valve shutting off. This sudden closure stops the flow of water abruptly, resulting in a shock wave that travels back through the pipes. The shock wave can create loud banging or hammering noises as it hits elbows, tees, and other changes in the pipe system.

Without protection, this hammering effect can eventually weaken joints and cause leaks or even damage pipes and fixtures. The sudden pressure changes involved can also loosen sediment inside pipes, leading to clogs or release trapped air that gets absorbed into the water stream. A water hammer arrestor provides a cushioning effect that dissipates the shock wave and protects the system.

How do water hammer arrestors work?

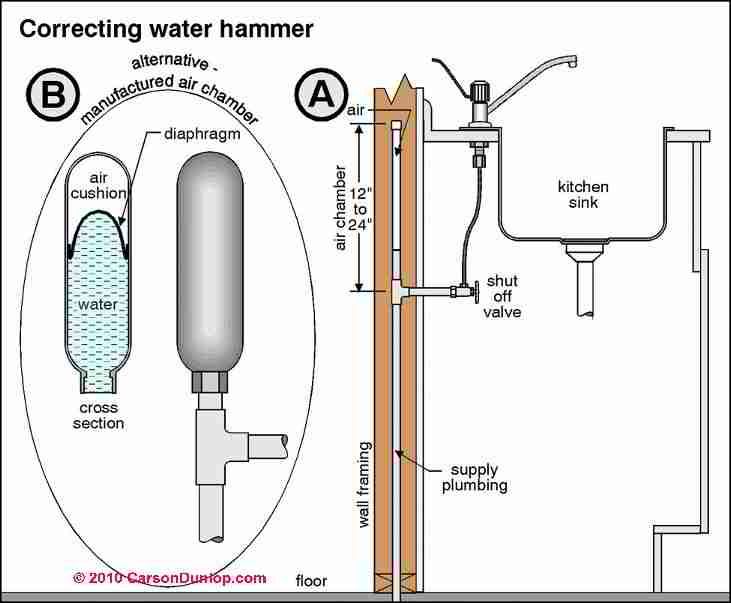

Water hammer arrestors contain a sealed air cushion that compresses to absorb the shock wave when water flow is suddenly halted. This cushions pipes, valves, and fixtures from the damage the shock wave can cause. The air chamber ultimately stops the wave and dissipates the energy so it cannot travel further through the system.

The most common type is the piston arrestor, which contains a piston sealed inside a cylinder filled with air or gas. As the shock wave enters, it pushes the piston, compressing the air like a spring. The compressed air then pushes back against the wave, countering it and preventing it from continuing through the system. The piston moves up and down to steadily dissipate the shock wave’s energy.

There are also bladder-style arrestors that use a flexible rubber bladder in place of the piston. The bladder compresses when the shock wave hits it then springs back to shape to counter the wave. Diaphragm arrestors use a flexible diaphragm made of material like steel instead of a piston.

Where should a water hammer arrestor be installed?

Ideally, a water hammer arrestor should be installed as close as possible to any fast-acting valves or quick shut-off devices in a plumbing system. This includes washing machine valves, dishwasher valves, ice maker valves, solenoid valves, and toilet flush valves. Arrestors can prevent water hammers caused by the sudden opening and closing of these types of fixtures.

It is also recommended to install arrestors near the ends of long pipe runs as shock waves have more time and distance to build up dangerous pressures in long stretches before being stopped. Placing arrestors near the fixture or appliance generating the wave stops and dissipates the shock immediately before it can propagate.

Does a water hammer arrestor’s orientation matter?

Most water hammer arrestors are designed to function properly regardless of their orientation. While manufacturers may provide diagrams showing the recommended positioning, in many cases the arrestor can be installed horizontally, vertically, or at any angle without impacting performance.

There are some exceptions depending on the arrestor design:

- Piston-type arrestors will typically have an optimal upright position to allow the piston to move freely up and down. Installing them horizontally can hamper piston movement. Check manufacturer instructions.

- Diaphragm arrestors also operate best in an upright position for proper diaphragm flexing. Horizontal installation can reduce effectiveness.

- Bladder-style arrestors are more position-agnostic since the flexible bladder can expand and contract in any direction when the shock wave hits.

To maximize performance, follow the manufacturer’s recommendations for that specific model of arrestor. But in most cases, the arrestor will work properly if installed horizontally instead of upright, or vice versa. The key factors are proper sizing for the pipe system and location nearest the source of the potential water hammer.

Installing a water hammer arrestor horizontally

While vertical installation may be preferred, installing a water hammer arrestor horizontally is usually fine and will not prevent it from working. Here are some tips for proper horizontal installation:

- Make sure pipes are adequately supported – Adding an arrestor introduces more weight, so use pipe hangers to bear the load.

- Allow proper space for servicing – Leave room around the arrestor for accessing unions and fittings.

- Mind inlet/outlet connections – Ensure you plumb the arrestor with flow moving in the right direction.

- Use isolation valves – Install shutoff valves before and after so the arrestor can be isolated for maintenance.

- Check for trapped air – Air pockets can reduce effectiveness, so install air bleed valves if needed.

- Secure components – Anchor components like valves to prevent strain on the attached arrestor.

With proper supports, clearance, and component choices, a horizontally-oriented water hammer arrestor will generally function just as well at preventing water hammers as a vertically installed unit would.

Installing a water hammer arrestor vertically

When possible, vertical installation is the optimal orientation for some water hammer arrestors. Follow these tips for proper vertical setup:

- Point inlet down – Connecting the inlet at the bottom allows trapped air to escape.

- Provide rigid support – Use anchors, brackets, or hangers capable of bearing the arrestor’s weight.

- Allow room to work – Leave space above and below to access fittings and valves.

- Mind connecting pipe – Make sure pipe can expand and contract without straining joints.

- Include isolation valves – Allows isolating the arrestor when maintenance is needed.

- Install air bleeds – Helps purge trapped air that could reduce effectiveness.

A vertically oriented arrestor often performs best, but follow manufacturer guidelines on appropriate installation. Proper anchoring, isolation valves, inlet/outlet orientation, and air bleeding contribute to maximum effectiveness in preventing water hammer damage.

Considerations when installing a water hammer arrestor

To get optimal performance from a water hammer arrestor, keep these tips in mind when planning installation:

- Size it appropriately – Match arrestor volume to pipe system volume.

- Install as close as possible to valves/fixtures – Within 12-18 inches is ideal.

- Minimize fittings and elbows – These can trap air and reduce efficiency.

- Anchor it properly – Prevent vibration/movement that causes wear or pipe strain.

- Include isolation valves – Allows servicing arrestor when needed.

- Install according to manufacturer instructions – Follow proper guidelines for that model.

- Maintain access – Retain clearance around arrestor for maintenance and repairs.

- Connect air bleeds and drains – Allows bleeding trapped air or drainage.

Proper installation positioning maximizes the arrestor’s ability to cushion water hammer shock waves. But factors like sizing, piping, isolation valves, and accessibility also impact its effectiveness and service life.

Conclusion

Most water hammer arrestors are designed to function properly regardless of orientation during installation. While some types like piston arrestors may have an optimal upright position, horizontal and angled mounting generally does not prevent them from working effectively. The key factors are correct sizing, proper location in the plumbing system near potential water hammer sources, and following manufacturer instructions for that specific model. With proper installation and maintenance, a water hammer arrestor should perform well to protect pipes and fixtures from water hammer damage whether mounted vertically, horizontally, or diagonally.