Yes, electrical boxes can be surface mounted in many cases. The key factors in determining if an electrical box can be surface mounted include the type of box, the wiring method, and any code requirements. In general, non-metallic boxes and flexible conduit wiring lend themselves well to surface mounting, while metallic boxes and rigid conduit may require extra work to surface mount.

Page Contents

Types of Electrical Boxes

The most common types of electrical boxes are:

- Plastic (or non-metallic) boxes – These are made from PVC or other plastic materials. They are lightweight and easy to install. Plastic boxes readily lend themselves to surface mounting.

- Metal boxes – Typically made from steel or aluminum. Metal boxes are more rugged but weigh more than plastic boxes. Surface mounting metal boxes is possible but requires additional steps.

- Masonry/concrete boxes – Designed to be embedded into concrete or masonry walls and floors during construction. Not suitable for surface mounting.

- Low voltage/communication boxes – Built for housing low voltage wiring for things like ethernet, coaxial, and fiber optic cabling. The small size makes these easily surface mounted.

For surface mounting an electrical box, plastic and low voltage boxes are the best and easiest options. Metal boxes can work as well but may need special mounts or adapters.

Wiring Methods

The wiring method used to bring power to the electrical box also impacts whether it can be surface mounted:

- Flexible conduit – Thin walled metal or plastic tubing that is easy to bend and route. Works very well for surface mounted boxes.

- Rigid metal conduit – Thick walled tubing that provides the most physical protection for wiring. Rigid conduit is meant to be securely fastened. Surface mounting boxes with rigid conduit requires adapters.

- Armored cable – Prefabricated cable with an outer metal covering. The flexible armored cable is simpler to surface mount than rigid metal conduit.

- Non-metallic sheathed cable – Also known as Romex. Easy to work with but not recommended for exposed surface mounting.

In most cases, wiring such as flexible conduit and armored cable will be the easiest for hooking up surface mounted boxes. Non-metallic cables like Romex are better suited for permanent installation within walls.

Electrical Code Requirements

The National Electrical Code (NEC) and local building codes contain standards for surface mounted electrical boxes. Key requirements include:

- Mounting height – Outlets and switches must be installed at standard heights above the floor for accessibility.

- Box type – Metal vs non-metallic boxes may be specified based on the location and use.

- Permitted locations – Codes define allowable locations for surface mounted boxes, such as maximum distances from doors and windows.

- Installation method – Specifics such as the type of fasteners to be used or providing a weatherproof seal.

- Conduit type – Rigid, flexible, or armored cable may be specified based on the environment.

Always consult the latest electrical code for requirements that apply to the exact box location and purpose when planning to surface mount.

Conclusion

Surface mounting an electrical box is a viable installation method in many residential, commercial, and industrial situations. The easiest scenarios involve mounting plastic or metal boxes designed for surface wiring using flexible conduit or armored cable. Rigid metal boxes and conduit require adapters. Be sure to check relevant electrical codes for any requirements that pertain to the exact installation location and box type.

| Box Type | Good for Surface Mounting? |

|---|---|

| Plastic | Yes |

| Metal | Yes, with adapters |

| Masonry | No |

| Low voltage | Yes |

Typical Surface Mounting Installation

Here is a typical installation using common materials and meeting code:

- Plastic non-metallic box rated for surface mounting

- 1/2″ flexible PVC conduit for wiring

- Box mounted at standard height with proper fasteners

- Weatherproof box, conduit, and seals for outdoor location

- GFCI receptacle or switch installed in box

This type of surface mount box would be completely compliant for a receptacle or switch located on an outdoor patio or exterior wall.

When to Avoid Surface Mounting

Surface mounted boxes may not be the best choice in these situations:

- New finished walls – Prefer to run wiring inside wall cavity and install recessed boxes.

- Concrete or masonry walls – Recessed boxes must be set when pouring concrete or building block wall.

- Interior aesthetic preference – Surface conduit and boxes have an industrial look.

- High security areas – Tamper resistant flush mount boxes preferred.

- Hazards like chemicals or flammable vapors – Sealed containment wiring should be used.

ConsiderFlush mount boxes will provide the most aesthetically clean and tamper resistant installation when feasible.

Advantages of Surface Mounting

- Faster, easier, and cheaper installation – No cutting into or patching existing finished walls.

- Accessible for changes and maintenance – Wiring and boxes are visible and can be accessed without demolition.

- Ideal for retrofitting existing buildings – Can be added more readily in older structures.

- Meets code for damp and wet locations – Weatherproof boxes and conduit seal out moisture.

- Flexible design – Conduit can be routed as needed on room surfaces.

For many retrofit and industrial applications, surface mounted boxes provide the most cost effective and adaptable installation method.

Tips for Surface Mounting

These tips will help ensure a professional surface mounted electrical box installation:

- Use mounting brackets for metal boxes to space off the wall surface.

- Seal openings and conduit connections to prevent water intrusion.

- Allow slack in flexible conduit for box movement and expansion/contraction.

- Use UL listed products like boxes, conduit, fittings, and wiring.

- Group parallel conduit runs using shared mounts.

- Fasten securely using specified fasteners like lag bolts.

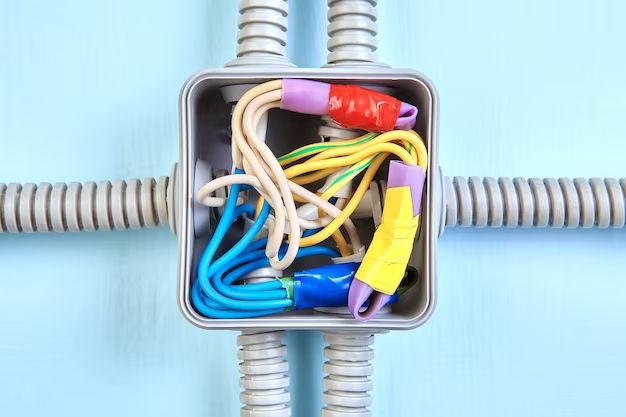

- Label and organize multiple circuit wiring inside boxes.

Proper planning, material selection, and installation per code guidelines results in safe and visually organized surface mounted electrical systems.

Summary

Surface mounting of electrical boxes is a viable installation method in many interior and exterior situations. Plastic and metal boxes designed for surface conduit wiring allow an accessible and professional looking installation. Rigid metallic conduit requires adapters to surface mount. Be sure to follow electrical code requirements for the specific location. Surface mounting is quicker than recessing into finished walls and ideal for retrofitting electrical circuits into existing buildings.