Page Contents

- 1 Can I move a small shed by myself?

- 2 Is moving a shed a one person job?

- 3 What are the steps to move a shed?

- 4 What tools do I need to move a shed?

- 5 How do you move a heavy shed?

- 6 Can I move a plastic shed by myself?

- 7 Can I move a metal shed by myself?

- 8 How do you move a large heavy shed?

- 9 What is the easiest way to move a shed?

- 10 Should I disassemble my shed before moving it?

- 11 Conclusion

Can I move a small shed by myself?

Yes, it is possible to move a small shed by yourself if you take the proper precautions and prepare accordingly. A small shed, defined as 8×8 ft or smaller, can potentially be moved by one person. However, having at least one other person assist will make the process significantly easier and safer.

When moving a shed solo, the most physically demanding parts will be dismantling, lifting, and reassembling the structure. Be sure you can safely handle the weight and awkwardness involved. Wear protective gloves and gear to avoid injury. Ramps, lever bars, and furniture sliders can aid with maneuvering the shed. Go slowly and take frequent breaks to avoid strain.

Carefully disassemble the shed, keeping hardware organized for reassembly. Beginning with the roof, detach panels working downward. Stack and load components securely onto a wheeled dolly, trailer, or other conveyance to transport. Use ratchet straps, ropes, or netting to prevent shifting. Maneuver the load at a controlled, cautious pace.

At the new location, clear a level site and reassemble from the ground up. Having an extra set of hands will be most useful at this stage, both for alignment and for safety. Anchor the shed properly against wind and other forces once fully reconstructed.

Moving a shed alone takes time, physical effort, and the right equipment. But with perseverance and preparation, it can be accomplished. Just be sure to adhere to safe practices. Call in help from friends or professionals if the project becomes overly strenuous or hazardous.

Is moving a shed a one person job?

Moving a shed is not ideally a one person job. While it may be possible for one sufficiently strong and determined person to move a very small shed over a short distance, most shed moving jobs will require at least two people for safety and practical reasons.

Some key factors indicating you need more than one person include:

– Shed size – Anything over 8×8 ft is realistically a two person task, while sheds over 10×12 ft often require three or more people. Larger sheds become unwieldy, heavy, and hazardous for one person to maneuver.

– Weight – Many shed components like floors, roof panels and frames can weigh over 100 lbs each. Lifting, carrying and controlling these alone adds risk of muscle strains or other injuries. Having a second person shares the load.

– Awkwardness – Long parts like wall panels or roof beams are unstable for one person to handle while moving. A second person provides stability, balance and avoids drops or accidents.

– Dismantling/Reassembly – Taking apart and putting a shed back together is easiest, fastest and safest with two or more people to align pieces and handle bolts and fasteners. A single person has to rush and take risks to brace components while securing them.

– Transport – Moving the disassembled shed pieces across property or onto a truck bed is far more controllable with two people minimum. Having a second person steering and braking the load prevents runaways.

For any shed over 5×5 ft or so, or weighing more than 75 lbs total, it’s wise to enlist at least one helper for a secure, efficient shed move. Handle minor repositioning solo, but tackle full disassembly and rebuilds as a team effort.

What are the steps to move a shed?

Moving a shed, even a small one, is not simply a matter of pushing it to a new spot. To move a shed safely and successfully follow these key steps:

1. Choose a new site – Select a level, stable, and accessible site for the shed, with adequate clearance.

2. Disconnect electricity – If wired for power, disconnect and cap all electrical lines leading to the shed.

3. Remove contents – Empty the shed completely, including shelves, tools, and other items.

4. Disassemble – Systematically take apart the shed, starting at the roof and working downwards. Keep all hardware and parts organized.

5. Prepare transport – Use a dolly, trailer, or lifting machine to securely transport the shed components. Strap down all pieces.

6. Level new site – Make sure the new shed site is cleared and leveled before moving the shed there.

7. Transfer components – Carefully move all shed sections, panels, and parts to the new location. Watch for any shifting or slipping.

8. Reassemble – Using original hardware, rebuild the shed from the ground up, making sure it is level, square, and secure.

9. Anchor shed – Once reassembled, anchor the shed to the ground per the manufacturer’s specifications.

10. Replace contents – Move shelves, tools, and other items back into the newly located shed.

Following these key steps helps ensure an orderly, safe, and successful shed move. Having at least two people makes the process far more manageable.

What tools do I need to move a shed?

Moving a shed requires having the right tools on hand to dismantle, move, and reassemble the structure properly. Recommended tools include:

– Hammer – To remove connecting nails and knock apart components

– Pry bar – For pulling nails, separating stuck pieces, and lifting

– Saw – For cutting connections between parts too difficult to dislodge otherwise

– Screwdrivers – Various types to remove screws and fasteners holding parts together

– Wrenches – For loosening and retightening nuts and bolts

– Ratchet straps – To securely tie down shed pieces onto transport carts or trailers

– Wheelbarrow/Dolly – For transporting lighter shed sections like doors, windows, and panels

– Ramps – For rolling shed parts up onto a vehicle or new foundation

– Level – To ensure shed is level during reassembly

– Measuring tape – For checking dimensions and clearances

– Work gloves – To protect hands from splinters, sharp edges, and pinch points

Having an electric drill/driver on hand can speed up disassembly and reassembly as well. And be sure to have replacements available for any hardware that becomes damaged or lost in the process. With the right tools at the ready, moving a shed can proceed smoothly and efficiently.

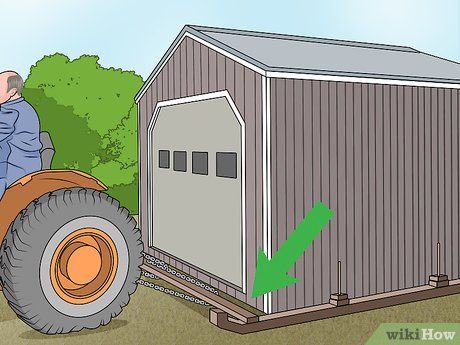

How do you move a heavy shed?

Moving a heavy shed requires careful preparation, equipment, and personnel to accomplish safely. Here are some tips:

– Know the weight – Determine the total weight by structure type and size. This governs how many people and what equipment is needed.

– Disassemble completely – Take the entire shed apart, including roof, walls, and foundation. Breaking it down makes each piece more manageable.

– Use leverage – Use pry bars and lever bars to detach stuck components without damaging them.

– Lift properly – Use leg strength when lifting, not your back. Keep the load close to your body to reduce strain.

– Get help – Have at least one, preferably two, strong helpers to share the workload and maneuvering.

– Use equipment – Dollies, pallet jacks, and carts allow moving heavy items without lifting the full weight at once.

– Rent forklift – For extremely heavy shed pieces, renting a forklift or telehandler can safely move components.

– Ramp it – Use sufficiently strong ramps to roll shed sections up onto a truck or trailer for transport.

– Strap it down – Securely strap shed pieces to the transport vehicle so nothing shifts enroute.

– Reassemble carefully – Have help positioning and stabilizing as you reassemble to avoid collapse or accidents.

– Anchor securely – Ensure the rebuilt shed is firmly anchored and cannot tip or blow over in winds.

With adequate help and the right equipment, even very heavy shed components can be moved safely. Take it slow and be prepared for a full day’s work.

Can I move a plastic shed by myself?

It is possible for one person to move a plastic shed, but only advisable for very small, lightweight designs. Most plastic sheds are assembled from resin panels and require at least two people to move safely.

Key factors to consider when moving a plastic shed solo include:

– Size – Typically only plastic sheds around 4×4 ft or smaller can reasonably be moved by one average-strength person.

– Weight – Each shed panel may weigh 50-75 lbs. Lifting, aligning, and fastening alone can be difficult.

– Awkwardness – Long walls or sloped roof panels are challenging to balance and maneuver by yourself.

– Assembly – Attaching panels and parts together is easiest with a helper to align and stabilize pieces.

– Transport – Carrying and loading panels into a vehicle is hazardous without assistance. Panels can bend or crack if not supported properly.

– Leveling – Getting panels square and even on a new base is tricky to accomplish alone.

– Wind resistance – Light plastic sheds are prone to catch the wind when dismantled, potentially causing damage or injury.

For sheds larger than 4×6 ft, or over 200 lbs total, it is strongly advised to recruit one or more helpers. While a solo plastic shed move is possible in theory, the difficulty and risks make it an unrealistic option in most cases.

Can I move a metal shed by myself?

Moving a metal shed without assistance is only recommended for very small and lightweight designs. Most metal sheds require at least two or more people to move safely and efficiently.

Factors making solo metal shed moves impractical:

– Size – Metal sheds larger than around 5×6 ft become extremely unwieldy and risky for one person to handle.

– Weight – Steel and aluminum panels and frames can weigh over 100 lbs each. Lifting these alone heightens injury risks.

– Sharp edges – Unprotected metal edges can easily cut skin and cause lacerations if not handled carefully.

– Rust and corrosion – Older metal sheds may have rusted or corroded parts that flake off or crumble when moved.

– Holes and gaps – Moving a partially disassembled metal shed alone leaves holes to trip over or body parts exposed to pinch points.

– Wind resistance – Long metal panels act like sails in the wind when freed for moving, challenging one person to control.

– Reassembly – Aligning and bolting together metal framing and sheets alone is difficult and prone to errors.

For sheds over 100 sq ft or 1,000 lbs total, having a team of 3-5 people is recommended for controlling the disassembly, transport and reassembly safely. Solo moves risk injury, damage and dangerous accidents.

How do you move a large heavy shed?

Moving a large, heavy shed is a challenging project requiring plenty of preparation, equipment and manpower. Here are some tips:

– Know weight – Weigh sections or calculate total weight based on size and materials. This determines how much help and gear is required.

– Recruit help – Have a crew of 3-5 strong helpers, depending on shed size. More hands make light work.

– Develop a plan – Make a plan for disassembly sequence, transport methods, reassembly order and timeline.

– Rent equipment – Use carts, dollies, lifts and ramps to move components with less lifting. Forklifts can carry heaviest pieces.

– Lift properly – Use legs, not back, for lifting. Keep loads close to body. Get help for awkward or overly heavy items.

– Load securely – Use ratchet straps, clamps and ties to keep loads immobilized on transport vehicles.

– Level the site – Ensure the new site is cleared, graded and compacted to be stable and level before reassembling.

– Shore up – Temporarily brace components, especially roof sections, during reassembly to prevent collapse accidents.

– Work safely – Wear protective gear, hydrate frequently, and take breaks to avoid overexertion or injuries.

– Anchor securely – Once rebuilt, anchor the shed deeply into the ground all around the foundation.

A large heavy shed move takes time and labor. But with ample helpers, gear, preparation and care, it can be transported and reconstructed safely at a new location.

What is the easiest way to move a shed?

The easiest way to move a shed is to break it down into modular pieces that can be transported on a truck or trailer and reassembled on site. This allows the following methods:

– Disassemble the entire shed, including roof, walls, floor panels and foundation. Stack panels flat and bundle framing for transport. This greatly reduces weight per piece.

– Use dollies, lifts, ramps and pulleys to roll or winch pieces into a truck bed rather than lifting. Secure with ratchet straps to prevent shifting.

– For larger sheds, disjoint floor panels to move individually rather than as one solid platform. This prevents having to lift the entire floor weight.

– Use levers and pry bars to separate stuck fasteners and release connecting joints. Avoid damage-causing hammering or forcing.

– Carry long lightweight parts like roof beams, trusses and rafters vertically rather than horizontally. This makes them easier to control.

– Place detached panels upright on edge rather than flat to utilize small transport vehicles. Strap them together so they don’t fall over.

– Rent a telehandler or forklift to move the heaviest shed components like concrete floor sections. No manual lifting required.

– Reassemble the shed starting on a level prepared site and using original hardware for proper fit.

Breaking down the shed into portable pieces makes moving much easier than attempting to relocate an entire rigid structure. Just be sure to catalog and organize all hardware for reinstallation.

Should I disassemble my shed before moving it?

It is strongly recommended to fully disassemble a shed before attempting to move it any significant distance. The main benefits of shed disassembly prior to moving are:

– Lower weight – With the shed broken down, individual components are lighter and easier to lift and transport than one rigid structure.

– Better maneuverability – Detached panels and sections have more flexibility to fit through gates, onto vehicles, around obstacles that a whole shed could not.

– Safer handling – Long panels and loose parts become hazards when moved assembled, risking damage both to the shed and movers.

– Accessibility – Disassembly allows access to move sheds from or into tight spaces not possible as one fixed unit.

– Less stress on structure – Twisting, flexing or dragging an intact shed strains the materials and connections, while disassembly shifting is minimized.

– Easier leveling – Detached pieces can be shimmed, blocked and leveled separately more precisely during reassembly.

– Identify issues – Any worn, damaged or corroded parts can be found and addressed when shed is dismantled prior to move.

– Lower cost – Requires smaller vehicle/equipment and less labor than moving a whole shed.

For anything beyond rotating a shed’s position onsite, taking it apart first makes the move far more controlled and safe. Just be sure all hardware and parts are labeled for reassembly.

Conclusion

Moving a shed without professional assistance is possible if all precautions are taken and preparations made. For sheds under 8×8 ft with few heavy components, one strong person working slowly can accomplish it safely through disassembly, transport, and reassembly. Larger or heavier sheds will require two or more people and perhaps equipment like dollies, lifts and ramps for a safe DIY move. Fully disassembling the shed is key, along with labeling parts and keeping hardware organized. With ample time, help, and the right gear, a shed can be relocated successfully as a DIY project. Just exercise caution and seek assistance anytime the move becomes too difficult or hazardous.