Connecting ABS and PVC pipes together is possible but not recommended for most applications. ABS and PVC are different types of plastic piping that have some compatibility issues when joined.

Page Contents

Quick Answers

- ABS and PVC have different expansion/contraction rates which can lead to joint failure over time.

- Chemical makeup of the plastics are slightly different which can cause bonding issues with glues and cements.

- Direct transition joints from ABS to PVC are prone to leaks and separation.

- Using proper transition fittings greatly improves the connection.

- ABS to PVC transitions should only be used for low pressure, non-critical applications.

While it is possible to connect ABS and PVC piping systems together, most plumbing codes and manufacturers recommend avoiding direct transitions joints whenever possible. The differences in the plastics can lead to potential joint failures down the road. However, with the proper transition fittings and cements, ABS and PVC connections can be made successfully in certain situations.

The Key Differences Between ABS and PVC

ABS (acrylonitrile butadiene styrene) and PVC (polyvinyl chloride) are both widely used thermoplastic piping materials in residential and commercial plumbing systems. Though they look similar and share some properties, there are some key differences that impact their compatibility:

- Chemical makeup – PVC contains more chlorine while ABS has more butadiene in its molecular structure. This variability affects what glues/cements work best.

- Impact strength – ABS has higher impact strength and is more ductile and forgiving under pressure.

- Heat tolerance – PVC has a higher heat distortion temperature, ABS softens more readily under heat.

- Thermal expansion – The thermal expansion and contraction rates of ABS and PVC differ. This can stress joints over temperature cycles.

- UV and chemical resistance – PVC has better UV resistance and chemical compatibility over ABS in some instances.

These differences, while subtle in some cases, have significant implications for successfully joining the two plastic materials. The variance in thermal expansion rates and chemical makeup in particular can undermine the long-term reliability of direct ABS to PVC transitions.

Can You Glue ABS and PVC Together?

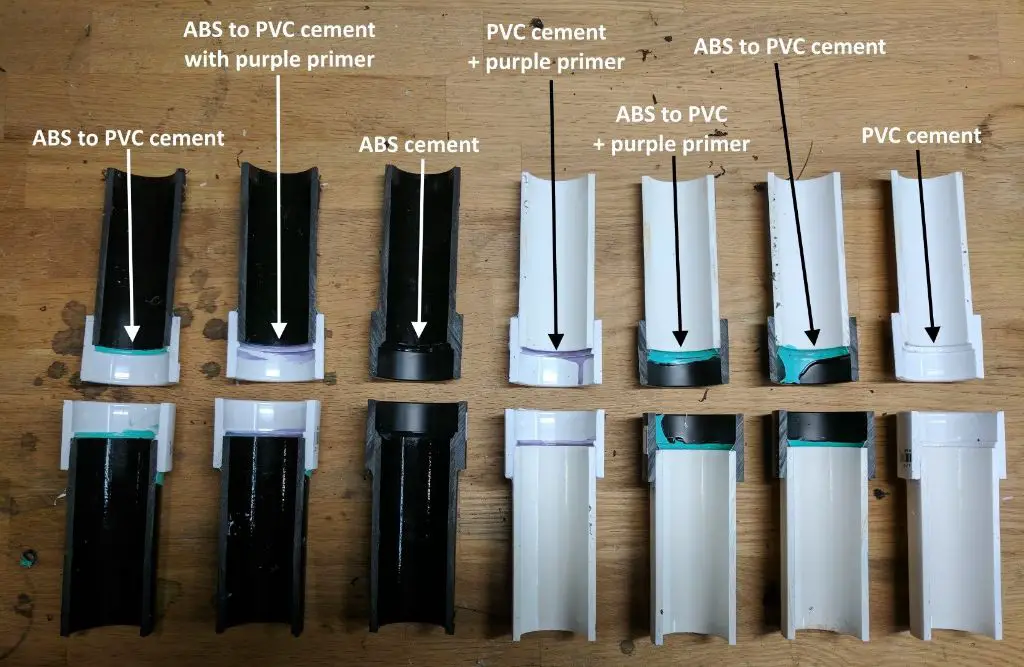

While it is possible to glue ABS and PVC together, doing so requires using the proper transitional cement/adhesive:

- ABS cement will not work well on PVC. ABS glue like Christy’s Red Hot Blue Glue contains compounds that only soften/weld ABS surfaces.

- PVC cement will not properly join ABS. PVC glue contains solvents tailored for softening/welding PVC only.

- Specialty ABS-to-PVC transitional glue contains a blend of solvents and compounds designed to work with both ABS and PVC and create a decent bond between them.

This specialty glue for joining ABS and PVC is available at most hardware stores and home improvement centers. Leading brands like Oatey and Christy’s make reliable ABS-to-PVC cements suitable for both DWV and pressure applications. Using these solvent cements significantly improves the strength and reliability of any PVC-to-ABS joint.

Proper Gluing Technique

When gluing ABS and PVC piping together, the proper glue application technique should be used:

- Surfaces must be cleaned and free of dirt, grease, moisture.

- Use applicator or brush to apply even coat of cement to both pipe ends.

- Press pipes together fully while twisting slightly to spread the glue.

- Hold joint together firmly for 30 seconds to a minute to allow proper cure time.

- Allow 8 hours or more cure time before pressurizing system or performing tests.

- Avoid bumping or disturbing the joint during the cure period.

This full coverage gluing method helps maximize the bonding strength of the joint. The transitional glue creates both chemical and mechanical bonds between the ABS and PVC to compensate for the differences between the materials.

Transition Fittings

For more reliable and trouble-free connections between ABS and PVC piping, transition fittings should be used whenever possible:

- Couplings – Use a no-hub type coupling with separate rubber sleeves and stainless steel band clamps. Allows small differences in pipe OD.

- Unions – Appropriate for smaller diameter pressure systems. Allows easy disconnect later.

- Transition adapters – Female and male threaded adapters to connect smaller threaded ABS and PVC components.

These purpose-made fittings for joining ABS to PVC provide a much stronger and more dependable connection. The separate rubber gasket seal compensates for any differences in pipe dimensions and the heavy-duty stainless steel clamps create a robust mechanical joint.

Examples of Appropriate Transition Fittings

| Fitting Type | Image Example | Description |

|---|---|---|

| No-Hub Coupling |  |

Heavy duty stainless steel shield with rubber sleeves to join and seal ABS and PVC pipes. |

| PVC to ABS Union |  |

Threaded union with rubber gasket seals for transitioning smaller diameter piping. |

| Threaded Adapters |  |

Allows connecting threaded PVC and ABS fittings and components. |

Applications to Avoid

While it is possible to connect ABS and PVC in low risk applications, here are some situations where a direct transition joint is not recommended and should be avoided:

- Underground piping – more prone to separation due to shifting soil and temperature changes.

- Pressure systems over 30 PSI – higher pressures increase risk of leaks and blowout.

- Potable water lines – contamination risks if joint fails.

- Swimming pool plumbing – chemical exposure and pressure fluctuations can degrade glue.

- High temperature drain lines – heat can accelerate chemical breakdown.

For these critical pressure or chemical applications, the safest option is to use transition fittings to join ABS and PVC segments rather than direct glue joints.

Testing and Inspection

Once an ABS to PVC transition joint is complete, it should be thoroughly tested before being put into service:

- Visually inspect for proper glue coverage and cure time.

- Pressure test with water up to system working pressure.

- Check for leaks and re-glue any problem joints.

- Retest repaired joints before returning to service.

- Periodically inspect connections for signs of separation or leakage.

Conducting these tests helps verify the integrity of the ABS-to-PVC bond. Catching any overlooked steps or issues before the system is activated reduces the chances of leaks or other problems down the road.

Conclusion

Connecting ABS and PVC piping with direct transition joints is possible but has some inherent risks that must be addressed. Using the proper transitional cement and following good gluing practices will provide the strongest bond possible. But for critical applications, transition fittings offer a much more reliable method of joining these dissimilar plastics.

In non-critical uses like low pressure drainage, well-glued ABS to PVC joints can have good functionality. However inspecting and testing all ABS-PVC connections is advised to help identify any overlooked flaws early on. With extra diligence taken during installation and inspection, even glue-joined ABS to PVC transitions can function dependably long-term.