Junction boxes, also known as electrical boxes or breaker boxes, are metal boxes that house wires, connectors and electrical devices within an electrical wiring system. Junction boxes allow for joining of wires and provide access to electrical systems for maintenance and repair. A key question for many homeowners and electricians is whether junction boxes can or should be installed outdoors. There are pros and cons to having an outdoor junction box that need to be carefully weighed when making this decision.

Page Contents

- 1 Quick Answer

- 2 Are Outdoor Junction Boxes Allowed by Code?

- 3 Requirements for Outdoor Junction Box Installation

- 4 advantages to an outdoor junction box:

- 5 Potential Drawbacks to Outdoor Junction Boxes

- 6 Installation Location Guidelines

- 7 Wiring Considerations for Outdoor Boxes

- 8 Junction Box Size Requirements

- 9 Grounding and Bonding

- 10 Outdoor Box Maintenance

- 11 Summary of Outdoor Junction Box Requirements

- 12 Conclusion

Quick Answer

Yes, junction boxes can be installed outdoors, however there are special considerations and requirements for outdoor installation. The main requirements are:

- The junction box must be weatherproof – designed to withstand the elements and prevent moisture ingress.

- Only weather resistant wiring methods can be used.

- Extra protection is needed for the conductors within the box.

- The box must be mounted securely.

- Proper clearances to openings must be maintained.

- Applicable electrical codes must be followed.

Provided these requirements are met, junction boxes can be safely installed outside. However, an indoor location is generally preferred when possible.

Are Outdoor Junction Boxes Allowed by Code?

Outdoor junction box installation is permitted by the National Electrical Code (NEC) provided the boxes meet code requirements. Section 314.15 of the NEC states that boxes installed outdoors must comply with the following:

- Be listed as suitable for wet locations.

- Have drainage holes in the bottom.

- Include provisions for installing rain-tight hubs or threaded conduit holes.

In addition, outdoor boxes must meet all other applicable box installation requirements in NEC Article 314. This includes limits on the number and size of conductors permitted in the box, minimum required wire bending space, and required clearances from openings in covers and doors.

Wet Location vs. Weatherproof Ratings

Junction boxes for outdoor use must be rated as either “wet location” or “weatherproof”. What’s the difference between these two ratings?

- Wet location – Approved for installations exposed to rain, snow, splashing water, hose-directed water, and other wet conditions. May allow for some water ingress.

- Weatherproof – Provides complete protection against weather conditions including rain, snow, sleet, ice, dust, and damage from external ice formation. Must prevent moisture ingress.

Weatherproof boxes provide a higher level of protection than wet location and are required for some types of outdoor installations. Check your local codes to determine which rating you need.

Requirements for Outdoor Junction Box Installation

Installing a junction box outside comes with additional requirements beyond a standard indoor box. Key requirements include:

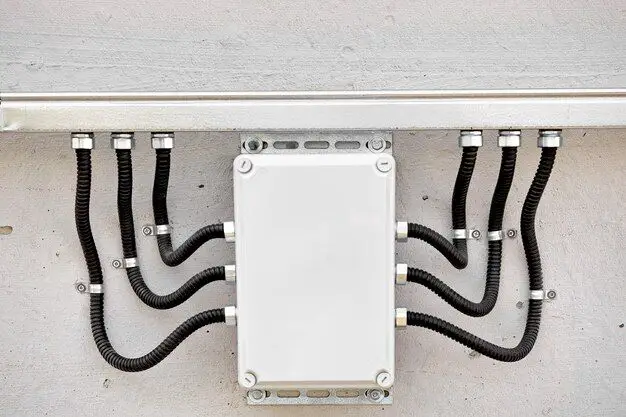

1. Weatherproof Box

As covered above, the box must be rated for wet locations or weatherproof depending on the specific installation location. Plastic boxes are common for outdoor use. Ensure any unused openings are properly plugged or sealed.

2. Weather-Resistant Wiring Methods

Outdoor junction boxes require wiring methods suitable for wet locations such as:

- Liquidtight flexible metal conduit (LFMC)

- Rigid metal conduit

- Intermediate metal conduit

- PVC conduit

- RTRC conduit

- Type UF cable (underground feeder)

- MI cable (mineral-insulated)

- THWN wires

Wiring insulations must be rated for outdoor use. NM cable (Romex) is not permitted for outdoor conduit runs.

3. Extra Protection for Conductors

The conductors inside an outdoor junction box require extra protection:

- Box knockout seals must be used.

- Bushings required where conductors enter through conduit ends.

- Clamps or fittings required where cables enter.

This prevents insulation damage and moisture wicking along wires into the box.

4. Secure Mounting

Outdoor boxes must be mounted securely to a wall or other solid structure using corrosion-resistant fasteners. This prevents movement that could compromise weathersealing and wiring terminations.

5. Proper Clearances

Any openings in the box must maintain required clearances from live parts:

- 1/4″ clearance for 200V or less

- 1/2″ clearance for 201V to 600V

This clearance prevents arcs or sparks to the exterior of the box.

6. Follow Electrical Codes

Adhere to all requirements in the NEC and any applicable local codes for outdoor electrical installations. This includes rules for grounding, GFCI protection, box sizing, conduit runs, and more. Review codes prior to installing any outdoor box.

advantages to an outdoor junction box:

There are several potential advantages to installing a junction box outside rather than inside:

Easier Access

An outdoor box is easily accessible without having to enter the building. This makes service quicker and more convenient.

Closer to Power Source

Locating the junction box closer to the electrical supply can mean shorter wire runs and reduced voltage drop. This improves efficiency.

Neater Installations

Outdoor boxes reduce the need to route conduit and wires into the building interior just to access a junction point. This cuts down on interior clutter.

Better Ventilation

The open air environment allows for better ventilation and cooling of electrical equipment compared to an enclosed indoor space.

Lower Fire Risk

Any faults or arcing within the box stays outside the building, reducing the risk of an interior fire.

Separation of Systems

An outdoor box clearly separates indoor and outdoor systems for safety and maintenance.

Aesthetics

No junction boxes mounted visibly on interior walls. All electrical systems contained unseen outdoors.

Potential Drawbacks to Outdoor Junction Boxes

While outdoor junction boxes provide advantages in certain installations, there are also some potential drawbacks to consider:

Exposure to Weather

Constant exposure to rain, snow, humidity, temperature swings, and UV rays can reduce the lifespan of a box. Weather damage is a risk.

Harder to Maintain

Outdoor boxes are more difficult to access for regular inspection and maintenance compared to indoor models.

Increased Corrosion

Outdoor conditions promote corrosion of the metallic box and components inside. Requires vigilance against rust.

Security Risk

Outdoor boxes are more easily tampered with or stolen since they are not inside the protected building envelope.

Higher Initial Cost

Weatherproof boxes and outdoor-rated wiring is more expensive than standard indoor junction box materials.

Temperature Extremes

Components may exceed temperature limitations in very hot or cold weather, impacting performance.

Exposure to Wildlife

Rodents, insects, and other wildlife can access an outdoor box and cause damage.

Installation Location Guidelines

Proper placement of the outdoor junction box is key to performance and safety. Follow these general guidelines on locating outdoor electrical boxes:

- Mount to a permanent structure on an exterior wall, column, or solid post.

- Locate box above ground level minimum 12 inches to avoid standing water.

- Protect box from physical impacts by vehicles, pedestrians, doors, or windows.

- Do not mount box below piping or outlets that may leak onto box.

- Allow sufficient access and work space around box for installation and future maintenance.

- Keep box shaded when possible to reduce solar heat gain.

- If flammable materials are nearby, maintain safe distances as per code.

- Orient box knockout openings downward to prevent moisture entry.

Also check clearance requirements in local electrical code before settling on a location.

Wiring Considerations for Outdoor Boxes

Any wiring entering or leaving an outdoor junction box requires special methods suitable for wet locations. Follow these guidelines:

- Use only approved outdoor wiring types rated for wet locations.

- Make sure conduit connections are raintight and secure.

- Use watertight conduit hubs at conduit entries.

- Seal around wires with rubber grommets or silicone.

- Use sweeps and long radius elbows on PVC conduit runs.

- Secure cables properly as they enter box.

- Provide drip loops on wires to prevent water ingress.

- Use liquidtight flex for short final connections.

Also size all wires and circuit protection per NEC rules accounting for reduction in ampacity from ambient temperature.

Junction Box Size Requirements

The size of the outdoor junction box must be adequately sized for the number of wires contained within the box. Consult the NEC for permitted box fill calculations based on:

- Total conductor fill area

- Number and diameter of conduits

- Size and number of devices contained

- Minimum required bend radius for wires

- Allowance for spare capacity in box

As a general rule, start with a 4×4 inch square box as the minimum size. Use larger boxes where needed to avoid overfilling.

Conductor Volume Allowance

| Conductor Size | Volume Allowance (cubic inches) |

|---|---|

| 18 AWG | 2.00 |

| 16 AWG | 2.25 |

| 14 AWG | 2.50 |

| 12 AWG | 3.00 |

| 10 AWG | 5.00 |

Multiply total conductor volume by the above allowances to determine minimum box size needed.

Grounding and Bonding

Proper grounding and bonding is critical for outdoor junction boxes to ensure safety. Follow these guidelines:

- Box must have a grounding terminal for equipment grounding wire.

- All noncurrent-carrying metal parts must be bonded to grounding terminal.

- Use bonding jumpers to ground box if mounted on non-conductive surface.

- Continuously ground metal conduit runs.

- Ground wires properly sized per NEC – generally sized to box overcurrent protection.

Inspect ground connections regularly as part of maintenance to ensure integrity.

Outdoor Box Maintenance

Preventative maintenance is important for any outdoor junction box installation. Follow these tips:

- Inspect box interior at least annually for corrosion, water ingress, or damage.

- Check condition of cover gasket and replace if deteriorated.

- Confirm all openings and unused knockouts are properly sealed.

- Check for loose wiring connections or damaged insulation.

- Clear any debris, plants, dirt, or mud around the box.

- Test box grounding using a multimeter annually.

- Repair any nicks, cracks, or damage to box as needed.

Perform maintenance more frequently in harsh environments or areas with frequent storms.

Summary of Outdoor Junction Box Requirements

To recap, key requirements for a code-compliant outdoor junction box installation include:

- Weatherproof NEMA 3R box rated for wet locations

- Corrosion-resistant box and hardware (stainless steel)

- Rain-tight threaded conduit entries with sealing locknuts

- Listed outdoor wiring methods (THWN, RMC, etc.)

- Tight cable clamps and conduit connections

- Box mounted minimum 12 inches above ground

- Sized according to NEC fill requirements

- Grounded and bonded per NEC Article 250

- Overcurrent protection for incoming circuit

- Regular inspections and maintenance

Following these guidelines helps ensure a safe, long-lasting outdoor junction box installation.

Conclusion

Junction boxes are permitted for outdoor installation provided they meet the requirements for weatherproof construction, adequate size, proper location, and other applicable electrical code rules. While outdoor placement has advantages in certain situations, an indoor location is generally preferred when feasible. Carefully weigh the pros and cons for your particular installation. All outdoor boxes require diligent maintenance to withstand the rigors of water, sun, dirt, and other environmental factors. Follow the recommendations in this article for best practices when installing outdoor junction boxes. Your electrician can also advise you on the optimal options to safely meet your electrical system needs.