Aluminum siding is a popular exterior home siding material due to its durability, low maintenance, and longevity. However, like any siding, aluminum can become damaged over time and require repairs. Small holes, cracks, dents, and surface corrosion are all common issues that can arise. Thankfully, it is possible to patch these types of minor damage to aluminum siding, extending its usable lifetime. Here are some quick answers to common questions on patching aluminum siding:

Page Contents

- 1 What causes damage to aluminum siding?

- 2 What types of damage can be patched?

- 3 What materials are used for aluminum siding patches?

- 4 What tools are needed for aluminum siding patching?

- 5 What is the basic process for patching aluminum siding?

- 6 What precautions should be taken when patching aluminum siding?

- 7 How long do aluminum siding patches last?

- 8 What are the costs to patch aluminum siding?

- 9 Conclusion

- 10 What are the alternatives to patching damaged aluminum siding?

- 11 What are some prevention tips for aluminum siding damage?

- 12 What are the main advantages and disadvantages of patching aluminum siding?

- 13 Conclusion

What causes damage to aluminum siding?

There are several common causes of damage to aluminum siding:

- Impact damage from objects striking the siding – This can cause dents, holes, bending, and other physical damage.

- Thermal expansion and contraction – Large temperature swings cause the siding to expand and contract, which can cause buckling and cracking over time.

- Corrosion – Aluminum can corrode when exposed to salt air or moisture. This causes pitting, flaking, and staining.

- Improper installation – Installation errors like fastening too tightly can cause buckling and cracking of the siding.

- Deformation from pressure – Backing into the home with a car, excessive wind or water pressure against the siding can deform it.

What types of damage can be patched?

Smaller types of damage like holes, cracks, dents, and minor corrosion can typically be patched. Larger areas of damage may require full siding panel replacement. Here are some guidelines on what can be patched:

- Holes – Holes up to 2 inches in diameter can usually be patched.

- Cracks – Cracks up to 12 inches long can typically be repaired.

- Dents – Minor dents up to 4 inches across can often be remedied with patching.

- Corrosion – Surface corrosion and pits that have not eaten through the metal can be patched after cleaning the area.

- Bends/bowing – Slight bends and deformation under 3 inches can sometimes be flattened out and patched.

Anything beyond this level of damage will typically require complete siding panel replacement.

What materials are used for aluminum siding patches?

There are a few main options for patch material:

- Aluminum patching compound – This is an aluminum-filled epoxy or polymer compound that can be shaped and hardened to fill holes and gaps.

- Aluminum sheet metal – Sheet aluminum can be cut and bent to patch holes and cracks in siding.

- Fiberglass mesh patches – These adhesive patches made of fiberglass and flexible polymer can cover small holes.

Aluminum sheet metal offers the closest match and blend for the existing siding. But patching compounds may be easier for filling in scratches, gaps, and holes where sheet metal would be difficult to fit.

What tools are needed for aluminum siding patching?

Here are the common tools needed for DIY aluminum siding patch jobs:

- Drill with metal bits

- Jigsaw

- Sheet metal snips

- Rubber mallet

- Putty knife or trowel

- Paintbrush and sprayer

- Coarse sandpaper

- Metal file

- Caulk gun

- Sealant/adhesive

For proper cutting, shaping, smoothing, adhesive application, and painting, these basic metalworking and home repair tools are very handy.

What is the basic process for patching aluminum siding?

Here is an overview of the aluminum siding patch process:

- Clean the damaged area thoroughly and sand it to rough up the surface.

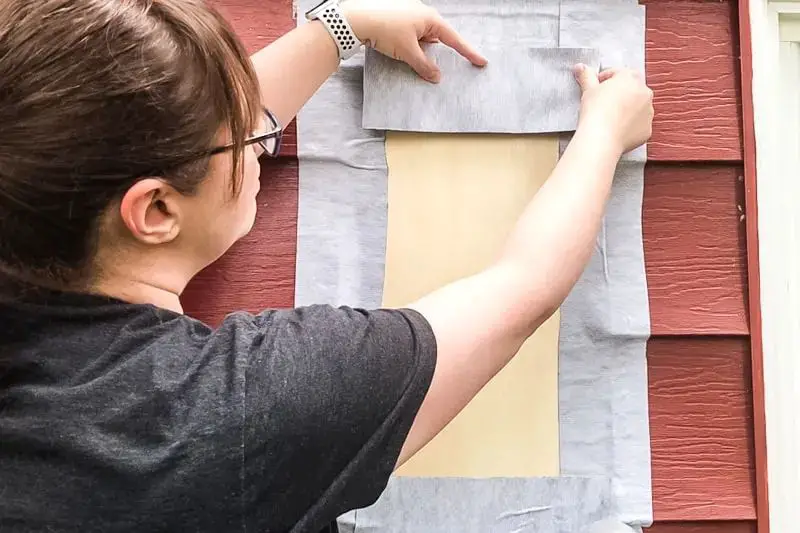

- Cut and shape the patch material (sheet aluminum or fiberglass mesh) to fit the damaged section.

- File or smooth the edges of the shaped patch.

- Apply adhesive or aluminum-filled patching compound to the back side of the patch.

- Firmly press the patch over the damaged area, smoothing it flush with the surrounding surface.

- Use caulk/sealant around the edges for waterproofing.

- Prime and paint the patch to match the existing siding color.

Take care to securely adhere the patch and provide waterproof sealing around its edges. Then properly prep and paint it to blend with the rest of the siding.

What precautions should be taken when patching aluminum siding?

Here are some important precautions to take for aluminum siding repairs:

- Wear protective gloves when handling and cutting aluminum.

- Work slowly and carefully when cutting sheet aluminum to avoid bending or crimping it.

- Make sure the patch fully covers the damaged area and extends at least 2 inches beyond it.

- Only apply repairs in dry weather when temperatures are above 55°F.

- Use high quality, flexible exterior-grade sealant/caulk around all patched edges.

- Avoid over-sanding or removing the baked enamel surface layer of the siding.

Rushing the job or damaging the surrounding good aluminum siding can make the problem worse. Careful surface preparation, proper patching techniques, and using quality materials can help achieve durable, long-lasting repairs.

How long do aluminum siding patches last?

When properly installed, aluminum siding patches can last for many years. Here are some factors that affect patch longevity:

- Patch material used – Aluminum sheet matching the original lasts longer than composite patches.

- Installation quality – Proper surface prep and waterproof sealing affects durability.

- Patch size – Smaller holes and cracks tend to have longer patch life than big patches.

- Siding age – Patching older, degraded siding may not last as long as patching newer siding.

- Ongoing maintenance – Keeping sealants fresh and repainting as needed extends patch life.

Patches applied to newer siding in good repair, using properly matched aluminum sheet material, and installed correctly can potentially last 10 years or longer in many cases.

What are the costs to patch aluminum siding?

For DIY repairs, the costs for aluminum siding patching are relatively low. Here are typical price ranges for materials:

- Aluminum sheet metal – $10 to $50 for a small sheet adequate for most patches.

- Aluminum patching compound – $10 to $30 per tub.

- Fiberglass mesh patches – $5 to $20 for a pack.

- Caulk/sealant – $5 to $15 per tube.

- Exterior primer and paint – $30 to $60 total.

So excluding tools, total material costs are roughly $50 to $200. Hiring a professional can cost $200 to $1,000 depending on the repair size.

Average Costs for Common Aluminum Siding Repairs

| Repair Type | Typical Range |

| Small hole or crack patch | $50 – $250 |

| Dent repair | $75 – $300 |

| Corrosion patching | $100 – $500 |

| Panel replacement | $200 – $1,000 |

As you can see, panel replacement is the most expensive option. But for minor damage, DIY patching can be very affordable.

Conclusion

Patching damaged areas of aluminum siding is often a viable repair option. For small dents, holes, cracks, and surface corrosion under 3 inches in size, patching can extend the service life of aluminum siding at a reasonable cost. Larger areas of damage or defects on aging, deteriorating siding may require full panel replacement. But by taking some simple precautions, using quality patching materials, proper tools, and techniques, smaller aluminum siding repairs can perform well for many years. This prevents the need for expensive siding replacement and maintains the exterior protection and appearance of the home.

Aluminum siding is a great low-maintenance exterior cladding for homes. Learning how to properly patch and repair it allows homeowners to easily care for their aluminum siding investment and keep it looking beautiful and functional for decades.

With a simple inspection to identify any problem areas and some affordable patch materials on hand, repairs to aluminum siding defects can be made quickly whenever needed. Holes, cracks, dents, and corrosion spots up to a few inches in size can be patched effectively with aluminum sheet material, fiberglass mesh, or patching compound designed for the job.

By following good surface prep, application, and waterproofing steps, DIY patches in aluminum siding can last 5-10 years or longer. This avoids the high cost of full siding replacement. Plus it allows the continued benefits of durable, long-lasting aluminum siding to be enjoyed.

So don’t despair too much over minor damage to aluminum siding. In most cases, patching can restore the integrity and good looks of the siding quickly and economically. Do a periodic inspection to spot issues early before they expand. And keep some basic aluminum patching supplies handy for when repairs become needed.

Tips for Successful Aluminum Siding Patching

- Clean area thoroughly – Remove dirt, chalky paint, oil etc. for good adhesion

- Rough up surface – Lightly sand area to help patch bind tightly

- Cut patch slightly larger than damaged spot

- Smooth all patch edges so they don’t protrude

- Use metal-specific primer before painting patch

- Caulk edges for waterproof seal

- Work slowly/carefully when cutting aluminum sheet

Follow these tips for patching that blends well and lasts. Be patient, take care not to further damage surrounding siding, and properly prep the repair area. Use high quality patching compounds or aluminum sheet that matches the original gauge and finish. The small effort required to properly patch problem areas on aluminum siding pays off for years down the road in maintaining your home’s exterior safely and attractively.

What are the alternatives to patching damaged aluminum siding?

Here are a couple options besides patching for repairing damaged aluminum siding:

Full Siding Panel Replacement

For more extensive damage spanning large sections of siding, replacement of whole panels may be needed. This involves removing and disposing damaged panels and installing new matching aluminum siding panels in their place. Replacing panels can become necessary if:

- Multiple patches would be required in one area

- Corrosion or damage extends across large portions of a panel

- Bends and deformation are too severe to patch

- The original aluminum siding is outdated and degraded beyond repair

Panel replacement provides a fresh, integrated repair free of seams and patches. But it is more labor intensive and raises costs over patching. Expect to pay $200 to $1,000 or more for siding panel replacement depending on how many need to be switched out.

Installing New Siding Over Old

Rather than patch or replace individual panels, some homeowners opt to install new vinyl or aluminum siding right over the existing damaged siding if the original is too far gone. This approach fully hides damaged areas under a brand new siding facade. It avoids panel removal work. But the extra siding layer slightly reduces curb appeal and property value compared to replacing only bad sections. Installing over old siding also has an added cost of $3,000 to $8,000 or more depending on home size.

What are some prevention tips for aluminum siding damage?

Here are some tips to minimize the chances of damage occurring to aluminum siding in the first place:

- Inspect siding seasonally and after major storms for signs of damage

- Keep landscaping trimmed back from touching the siding

- Use mild cleaners and avoid pressure washing, which can push water into seams

- Re-caulk any gaps around windows, doors, and trim annually

- Consider installing siding protection in areas prone to impact damage

- Maintain proper drainage and slope around the home’s foundation

- Repaint aluminum siding on schedule, typically every 8-12 years

Being proactive with regular inspections, maintenance, and preventative care makes expensive repairs less likely down the road.

Common Causes of Aluminum Siding Damage

| Damage Cause | Prevention Tips |

| Impact from objects | Install protective barriers/padding in vulnerable areas |

| Thermal expansion issues | Allow adequate expansion joints during installation |

| Moisture penetration | Re-caulk annually, improve drainage |

| Deformation from pressure | Avoid pushing/scratching siding when cleaning |

| Improper Installation | Have certified installer adhere to standards |

Being aware of what typically causes aluminum siding damage allows smart preventative action to be taken.

What are the main advantages and disadvantages of patching aluminum siding?

Advantages

- Low cost compared to full panel replacement

- Less labor intensive than replacing siding sections

- Preserves existing siding finish and appearance

- Can repair isolated damage versus whole panels

- Widely available patching materials

Disadvantages

- May not last as long as panel replacement

- Can appear slightly mismatched over time

- Not suitable for large damaged areas

- Surface preparation is important

- Painting required for best color match

For minor isolated damage, patching provides an economical repair. But it requires skill for best results and has limitations versus full siding replacement when damage is extensive.

Conclusion

Aluminum siding is designed to be low maintenance, but occasional damage does occur. Cracks, holes, dents, and corrosion are common problems that can arise on older or impacted siding. Thankfully, patching offers an affordable solution for repairing small areas up to a few inches in size. With proper preparation, high quality materials, and careful installation, aluminum siding patches can restore the look of damaged areas and provide many additional years of service life.

While patching has some disadvantages versus full siding replacement, it is a fraction of the cost in most cases. For isolated damage under 3 inches, aluminum, composite, and fiberglass patching materials can often remedy the issues at under $100 in material costs. Larger or more widespread problems may require complete panel replacement, but minor damage is what patching handles best.

To maximize durability of patches, proper surface prep, weatherproof sealing, and paint matching is key. But when done right, patches are far more economical than siding replacement and can maintain the protective qualities and appearance of aluminum siding for the long run. So don’t despair when small dents, cracks, and corrosion happen. In many cases, patching provides just what is needed to keep aluminum siding in shape and looking great on your home’s exterior.