Page Contents

Quick Answer

Yes, you can and should put a filter on a well pump. The filter helps protect the pump from damage and extends its life by preventing sediment, grit and other debris from entering the pump. The type of filter used depends on the type of pump, but common options are foot valves, screen filters, sediment filters and sand traps.

Why Put a Filter on a Well Pump?

There are several important reasons to use a filter on a well pump:

- Protects the pump from damage – Well water contains sediment and debris that can wear down pump components like the impeller. A filter prevents this grit from ever reaching the pump.

- Extends pump life – By keeping sediment away from the pump, a filter reduces wear and tear and allows the pump to last longer before needing repair or replacement.

- Improves performance – Sediment can clog up the pump impeller and reduce water flow. A filter maintains optimal water flow.

- Reduces maintenance – Filters mean less wear inside the pump, so less frequent maintenance is required.

- Provides cleaner water – Filters trap debris and sediment to deliver cleaner water to your home.

- Lowers electricity costs – Clean pumps require less energy to operate than clogged pumps.

- Prevents plugging – Filters stop sand and sediment from plugging pipes and water lines.

The nominal upfront cost of a filter is worth it for all these benefits. It is highly recommended to install a filter with any new or replacement well pump.

Where to Install a Well Pump Filter

The filter should be installed on the inlet pipe leading into the well pump. This is located down inside the well casing itself, below the static water level.

Placing it here prevents sediment from ever entering and damaging the pump. It also allows for easier access and maintenance than trying to install it on the outlet pipe.

Submersible Pumps

For submersible well pumps, the filter is installed at the bottom of the drop pipe that connects to the pump. A screen filter or foot valve is commonly used.

Jet Pumps

On shallow well jet pumps, the filter is placed at the inlet to the ejector, which is located at the bottom of the well. Foot valves or screen filters are again typical choices.

Above Ground Pumps

For above ground pumps, a Y-strainer type sediment filter is installed on the inlet line leading down into the well. This should be positioned as close to the top of the well casing as practical.

Types of Well Pump Filters

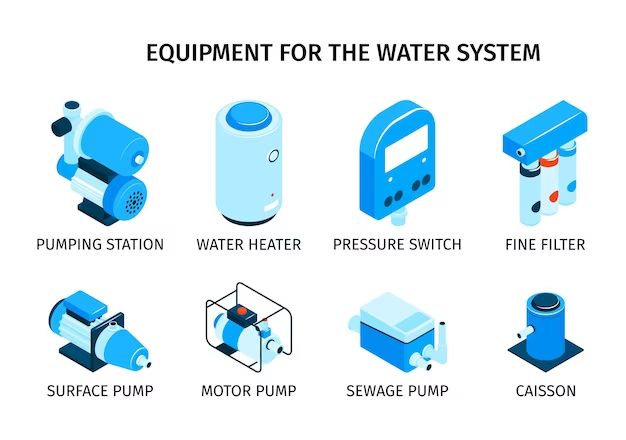

Some common types of filter used to protect well pumps include:

Foot Valve

This is a check valve installed at the bottom of the inlet pipe that only allows water to flow into the pump. It prevents debris settling when the pump shuts off. Simple and inexpensive.

Screen Filter

Made from perforated metal or mesh that allows water in while keeping sediment out. Available in different mesh sizes. Easy to service.

Basket Strainers

Made from wire mesh formed into a basket shape. Collects debris for easy cleaning. Budget-friendly option.

Y-Strainers

A Y-shaped fitting that holds a removable strainer basket. Allows flow in one end and out the other. Easy maintenance.

Sediment Filter

Uses a fibrous pad or other media to trap sediment. More surface area than strainers for fine filtration. Requires replacement when clogged.

Sand Traps

A section of oversized pipe that slows velocity to allow sand to settle out before the pump inlet. No maintenance required.

Automatic Filters

Self-cleaning filter that periodically backflushes away debris. More expensive but less maintenance.

How to Size a Well Pump Filter

Proper sizing of the filter is important for several reasons:

- Prevent excessive pressure drop – An undersized filter can restrict flow too much.

- Avoid clogging – Size for proper flow rate and debris capacity.

- Validate pump capacity – Don’t undersize for the pump flow rate.

- Allow adequate sediment capacity – Match debris volume expected between cleanings.

- Meet service requirements – Factor in required maintenance intervals.

Filter sizing considers the pump flow rate, piping size, water quality, service access and required maintenance schedule.

Manufacturers provide sizing guides and your pump installer can also recommend the optimal filter size and type for your specific well system. Oversizing is preferred to undersizing.

How to Install a Well Pump Filter

Installing a filter on a well pump requires working down inside the well casing itself. Proper safety precautions must be taken against hazardous gases and confined space risks. Well work should be done by an experienced pump installer or plumber unless you have specific well training.

However, the basic installation steps are:

- Shut off power to the pump circuit at the breaker.

- Remove the existing well cap or seal.

- Measure total well depth and depth to water.

- Calculate required piping lengths.

- Assemble filter and inlet pipe sections.

- Lower piping with filter into well and position filter at proper depth.

- Connect inlet pipe to pump discharge.

- Reinstall well cap and seal.

- Turn power back on and test pump operation.

The filter should be positioned near the bottom of the well, below the water level. Foot valves must be submerged to operate. Follow manufacturer’s instructions for that filter model.

Proper alignment, leak-free gaskets, and secure connections are critical. Check for obstructions or debris in the well casing while doing the work.

Maintaining Your Well Pump Filter

Regular maintenance ensures a well pump filter continues removing sediment and debris as designed. The steps involved depend on filter type:

Screen Filters

Remove and physically flush/rinse the screen element to remove collected sediment. Inspect for damage and replace if deteriorated.

Basket Strainers

Pull up the basket and empty out any debris. Rinse out with water. Check and replace gaskets as needed.

Sediment Filters

Replace disposable filter cartridges when pressure drop indicates the media is clogged. Annual cartridge replacement recommended.

Sand Traps

Periodically pump the well to purge any accumulated sand and sediment from the bottom of the casing.

Automatic Filters

Self-cleaning models require less routine maintenance. Inspect per manufacturer. Replace filter elements as needed.

Ideally, check and service the filter at least annually. Increased sediment, reduced flow or pump issues can indicate maintenance is overdue. Well work requires proper training and safety precautions.

Conclusion

Installing a high-quality filter on your well pump provides major benefits for pump longevity, efficiency and delivered water quality.

A variety of filter options exist to match different pump types and well conditions. Proper sizing for flow rate and sediment capacity is important.

Have your well pump installer recommend the right filter and location to protect your pump. With periodic cleaning and replacement, it will help ensure reliable water supply from your well.