Page Contents

Quick Answer

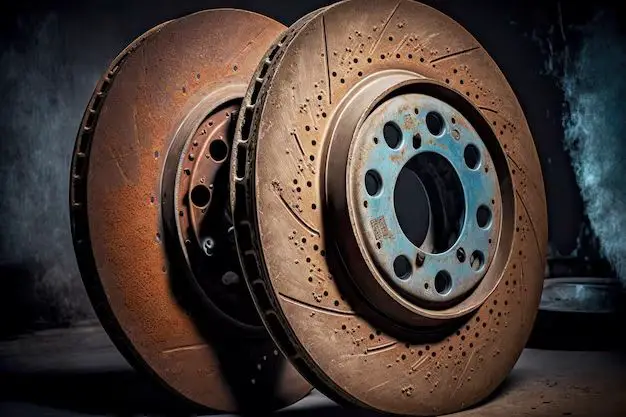

Yes, it is possible to remove rust from brake rotors, but the process requires some work. The most common methods for removing rotor rust are sanding, using a wire brush, or media blasting to strip the rust off down to bare metal. For lightly surface rusted rotors, sandpaper and emery cloth can work well. Heavily rusted rotors usually need more aggressive treatments like wire brushes, naval jelly, or media blasting to fully remove stubborn rust.

What Causes Brake Rotors to Rust?

Brake rotors can start to rust for a few different reasons:

- Exposure to moisture – Wet conditions like rain or snow can cause brake rotors to rust if the vehicle sits unused for an extended period of time. Prolonged humidity in the air can also lead to surface rust on rotors.

- Lack of use – When a vehicle goes unused for weeks or months at a time, the brake rotors are prone to rusting from environmental exposure.

- Damage to the rotor surface – If the outer layer of the rotor gets chipped or damaged, it exposes the raw steel underneath which can then oxidize into rust.

- Using abusive braking techniques – Hard braking with pads that deposit a lot of metallic dust on the rotors can increase corrosion over time.

The iron and steel used to make brake rotors readily reacts with oxygen to form iron oxide, or rust, when exposed to moisture. Frequent use of the brakes helps keep the rotors clean and dry by wearing away any rust that forms on the surface.

Should You Replace or Resurface Rusted Rotors?

Whether heavily rusted rotors need to be replaced or can be resurfaced depends on a few factors:

- Rotor thickness – Rotors have a minimum thickness specification, usually stamped on the mounting face. If rust has caused too much metal loss and reduced the rotor below spec, it will need replacement.

- Severity of rust – Light surface rust can be removed to restore the rotors. But deep rust pitting that affects the rotor friction surface needs replacement.

- Rotor runout – Excessive runout from uneven rust makes resurfacing difficult. Bad runout usually requires new rotors.

- Quality of braking surface – The rotor surface must be smooth after rust removal. Deep pits or ridges mean replacement is better than attempting to resurface.

In general, rotors with light rust can be resurfaced, while extensive rust damage is better addressed by replacing the rotors.

How to Remove Rust from Brake Rotors

Here are some effective methods for removing rust from brake rotors:

Sanding

Using sandpaper and emery cloth to manually sand rotors is a simple rust removal process. Start with a coarse grit like 80 to 100 to aggressively cut into rust, then smooth the surface with 180 to 220 grit. Sanding works best for minor surface rust.

Wire Brushing

A handheld wire brush or rotary wire wheel can scrub off heavy rust layers. Powered wire brushes cover large areas quickly. Brush across the rotor surface until all rust is removed. Wire brushes work well for medium to heavy rust buildup.

Naval jelly is a gel-like metal corrosion remover. Applying naval jelly to rusted rotors helps lift and dissolve rust. Use a plastic scraper to remove the jelly and let the rotor dry completely afterwards. Naval jelly works on heavily rusted and pitted brake rotors.

Media Blasting

Media blasting with sand, glass beads, baking soda, or walnut shells is extremely effective at stripping all rust off down to bare metal. Many brake shops have media blasting cabinets. This aggressive method works even for thick rust buildup.

Vinegar Soaking

Soaking heavily rusted rotors in vinegar can help dissolve and loosen rust. Submerge the rotor in undiluted white vinegar for several hours. Scrub with a wire brush and rinse clean. Repeat as needed for stubborn rust.

Tips for Preventing Brake Rotor Rust

Here are some tips to help avoid rusty brake rotors:

- Drive regularly to keep rotors dry from use.

- Wash wheels often to prevent road grime and salt buildup.

- Wax paint on wheels to prevent brake dust corrosion.

- Avoid puddles and don’t wash undercarriage with high pressure.

- Store vehicle indoors or use a car cover if sitting long term.

- Change brake fluid regularly to prevent rotor corrosion.

Catching and removing rust buildup early is key to extending rotor life. But some rust is unavoidable with time. Knowing how to clean and resurface rotors helps reduce costs compared to always replacing them.

Conclusion

Rust formation on brake rotors is a common problem stemming from moisture exposure, lack of use, and damage accumulation over time. Mild surface rust can usually be removed through sanding, wire brushing, or naval jelly application. Heavier rust requires more aggressive techniques like media blasting or vinegar soaks. The key considerations are measuring rotor thickness, runout, and surface condition to determine if resurfacing is possible or replacement is required. With the right methods, removing rust from brake rotors is very doable and helps prolong their lifespan. Implementing precautions like regular washing, indoor storage, and frequent driving can also prevent rotor rust in the first place.