When it comes to drilling metal, using the right drill bit is extremely important. Regular drill bits made for drilling into wood or plastic will not work well on metal surfaces. Metal is much harder and requires specialty drill bits made specifically for cutting and drilling metal efficiently. So yes, you do need a special drill bit made for metal any time you need to drill into metal.

Page Contents

Why You Should Use Specialized Drill Bits for Metal

Trying to use a standard wood drill bit on metal will likely result in the bit becoming damaged very quickly. High-carbon steel alloys that metal is made out of will wear down the cutting edges on regular drill bits not designed for metal. This can lead to frustrating experiences where the drill bit slips across the surface of the metal preventing you from drilling a hole.

Drill bits made specifically for metal cutting have a number of important design differences that make them optimized for the task:

- The tips are made of extremely hard materials like cobalt or carbide to allow them to cut through tough metal alloys.

- They have a steeper angle on the cutting edges which allows them to scrape away metal shavings efficiently.

- The flutes are designed to efficiently channel metal shavings out of the hole during drilling.

- Special coatings reduce friction and heat during drilling to prevent wearing down the drill bit prematurely.

These specialized design factors make drill bits for metal considerably more effective and durable when drilling metal. This allows clean, fast holes and prevents damage to the drill bit even when drilling through sturdy steel alloys.

Types of Drill Bits for Metal

There are a number of different metal drill bit types that are designed to drill specific types of holes in various metals:

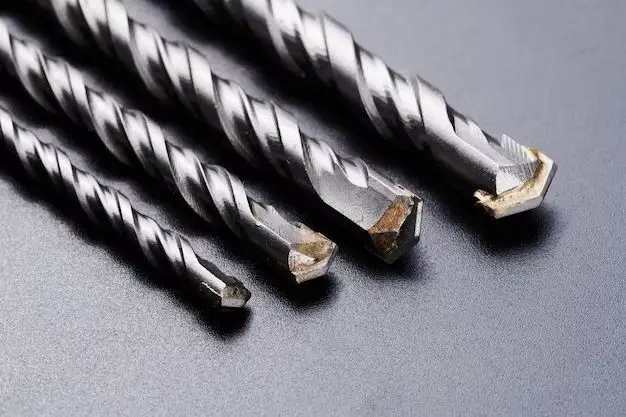

Twist Drill Bits

These are the most common and general-purpose drill bits for drilling metal. Twist drill bits have a pointed tip and two rotating cutting edges that scrape away metal to penetrate the hole. They can drill metal efficiently and come in many different sizes. Twist drill bits are inexpensive and can drill most standard holes in metal.

Brad Point Bits

Brad point bits have a center spur point to keep the drill bit stable and prevent walking across the metal surface when starting a hole. This allows precise placement of the hole and clean entry points. The cutting edges remove material around the initial point to open the hole to full width.

Step Drill Bits

Step drill bits have multiple cutting surfaces of increasing diameter down the length of the bit shank. This allows drilling holes of different diameters using a single bit. Step drill bits are very useful when drilling holes in metal for attaching hardware or running wires and cables through.

Metal Hole Saw Bits

Metal hole saws have a drill bit tip in the center and circular saw-like cutting edges around the perimeter. This configuration can cut wide, clean holes in metal in a range of sizes. They are ideal for applications like installing door knobs or cutting electrical junction box openings in metal panels.

Cobalt Drill Bits

Cobalt drill bits are extremely hard and optimized for drilling through hardened steel and other difficult metals. The cobalt material adds strength to the cutting edges allowing them to cut tough alloys easier while resisting wear. Cobalt bits are more expensive but necessary for drilling very hard metals.

Choosing the Best Drill Bit for a Metalworking Project

Selecting the right drill bit type and size for working with metal depends on several factors:

- Metal Hardness – Harder metals like hardened steel require cobalt or carbide tipped bits to drill effectively. Softer metals can be drilled with standard twist bits.

- Hole Size – The drill bit must match the desired hole diameter but also reach adequate depth. Long, skinny bits are prone to breaking in deep holes.

- Hole Precision – Brad point bits improve precision and reduce walking when starting a hole in an exact location.

- Material Thickness – Step bits or hole saws work best for cutting different sized holes in metal panels for hardware installation, wiring, etc.

- Cost – Specialty drill bits can be more expensive. Standard twist bits work for many basic DIY metal hole drilling tasks.

Considering these factors will ensure you select drill bits that will work quickly and effectively for the metal and holes you need to complete your particular project.

Drilling Metal Properly

While having the correct drill bit is essential, there are additional things to keep in mind when drilling metal to ensure the best results:

Use Cutting Fluid

Cutting fluid like WD-40 helps keep the drill bit cool and lubricated when drilling metal. This prevents overheating and reduces friction for smoother drilling. The fluid also helps flush away metal shavings from the cut to prevent clogging.

Use Low Speeds

Drilling metal requires lower speeds than wood or plastic to prevent damage to the drill bit. Follow the manufacturer’s speed recommendations for metal drilling based on bit size and metal hardness.

Apply Pressure in Steps

Applying too much pressure when starting a hole can cause the bit to walk or snap. Apply light pressure to start the hole, and slowly increase pressure as the hole deepens once the bit is stabilized.

Back Out Regularly

Frequently back the drill bit out of deep holes to clear away metal shavings. This prevents binding and overheating of the bit during extended drilling.

Clamp Your Work

Clamping the metal piece you are drilling helps prevent bending or movement allowing cleaner, more precise holes. Never hold small metal pieces by hand while drilling them.

Conclusion

Drilling metal requires specific drill bits designed to cut metal efficiently. The most common include twist bits, brad point bits, step bits, hole saws, and cobalt bits. Matching the bit to factors like metal hardness, hole size, precision, and material thickness results in the best performance. Additional techniques like using cutting fluid, the proper speed, pressure control, clearing chips, and work clamping also lead to improved drilling results in metal. Following these drill bit selection and drilling practice tips will make your next metalworking project much easier.