Whether a breaker panel needs a cover is an important electrical safety question for any homeowner. The short answer is yes, breaker panel covers are required by code in the United States and Canada. Breaker panel covers, often called dead fronts, are a crucial protective barrier between energized electrical components and people or objects that could come into contact with them. Leaving a breaker panel uncovered poses a serious risk of electric shock, burns, fires, or equipment damage.

Page Contents

What is a breaker panel cover?

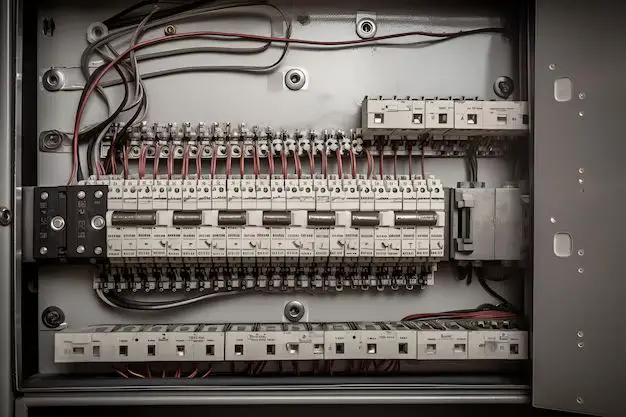

A breaker panel cover, also known as a dead front, is a protective barrier that covers the front of an electrical breaker panel. It has holes or openings that allow access to switches, breakers, and wiring, but prevents accidental contact with live electrical parts inside the panel. Breaker panel covers are typically made of an insulating material like plastic, metal, or a combination of both. They mount to the front of the breaker panel enclosure and are held in place by screws or other fasteners.

Types of breaker panel covers

There are a few different types of breaker panel covers:

- Plastic covers – Made of durable plastic material, these are the most common residential breaker panel covers. They are inexpensive and provide good protection.

- Metal covers – Made from coated sheet metal, these covers offer enhanced durability and fire protection. Often found in industrial settings.

- Clear plastic covers – These allow you to see inside while keeping the panel face covered. Helpful for troubleshooting electrical issues.

- Insulated covers – Designed for maximum insulation and shock protection. Some have insulation built into the cover itself.

While the materials and specific design may vary, all breaker panel covers serve the same essential safety functions.

Why are breaker panel covers required?

Breaker panel covers are universally required by electrical codes and standards like the NEC, CEC, NFPA 70, and CSA C22.1. There are a few key reasons covers are mandated:

- Prevent electric shock – Exposed breakers and bus bars present a serious risk of dangerous or fatal electric shock. Covers provide a protective barrier.

- Avoid arc flash hazards – If live conductors arc internally, the cover contains and deflects the dangerous flash energy away from people.

- Protect from debris – Covers prevent dust, vermin, insects and other debris from entering the panel causing faults.

- Deter tampering – Covers discourage unauthorized handling of breakers by untrained people.

The National Electrical Code (NEC) specifically mandates covers in article 110.27 and article 408.7. Breaker panel covers are considered vital safety equipment and are never optional in a code-compliant installation.

When are panel covers legally required?

Breaker panel covers are required any time a breaker panel is installed or accessible. Specifically, the NEC mandates covers in the following scenarios:

- All new breaker panel installations must have a cover installed before power can be connected.

- An unused opening in an existing breaker panel must be covered to protect against accidental contact.

- Any time access to a panel cover is modified by cutting or drilling holes, the integrity must be maintained by installing shields or other protection.

- In public-access areas, covers must be kept closed unless opened by an authorized person to perform maintenance.

- Covers must be re-installed after any electrical work on the breakers, bus bars or interior wiring is completed.

Essentially, breaker panel covers are mandatory when the breaker panel is energized and physical access is possible. The only exception is when the panel cover has been temporarily removed by a qualified electrician servicing the breaker panel.

Can you remove a breaker panel cover?

Breaker panel covers can only be legally removed under limited circumstances, according to NEC and local electrical codes. The general guideline is that covers may temporarily be removed by a qualified electrician when necessary to perform testing or repairs. Situations where it is acceptable to remove a panel cover include:

- A licensed electrician needs access to check or maintain equipment inside the panel.

- Electrical troubleshooting is needed to find the cause of problems.

- Upgrading wiring, breakers or other components in the panel.

- A home inspection is being conducted by a qualified professional.

In all cases, the breaker panel cover must be immediately reinstalled after the work is complete. The cover should never be left off longer than necessary. Untrained homeowners should never remove covers themselves.

Dangers of removing panel covers

Removing a breaker panel cover exposes very hazardous live electrical equipment. Without the cover, the risk of electrocution, arc flash burns, or blast injuries rises exponentially. According to NFPA 70E safety standards, no part of the body should come within 4-6″ of unprotected electrical conductors. That is nearly impossible with an uncovered panel. Some specific dangers include:

- Direct contact with 240V bus bars causing electrocution.

- Short circuits and arc flash triggering violent explosions.

- Accidentally switching off critical circuits like smoke detectors.

- Severe shock or burns from exposed breaker terminals and wiring.

Leaving a breaker panel cover off for an extended period is illegal and can result in catastrophic injuries or property damage. Cover removal should be avoided unless absolutely necessary, and conducted with extreme caution.

Can you replace a breaker panel cover yourself?

Homeowners should not replace breaker panel covers themselves unless they are fully qualified to work on electrical equipment. Federal and local laws prohibit untrained persons from working on wiring and breaker panels. However, with proper training and precautions, a homeowner may be legally permitted to swap out a broken panel cover themselves in some jurisdictions.

When DIY replacement may be possible

It may be possible for a homeowner to replace a breaker panel cover in specific situations such as:

- The panel cover is clearly damaged or broken, not just removed.

- The main breaker switch can be turned fully OFF while the cover is off.

- All laws and permits for homeowner electrical work are followed.

- Proper safety protocols and gear (PPE, insulating tools etc.) are used.

- The homeowner is trained and competent in electrical equipment.

Safest practice is to have a licensed electrician replace any damaged panel cover. But if the above conditions are met, replacing an identical cover may be DIY-able in some cases. Always check local regulations.

Dangers of DIY panel cover replacement

Attempting a DIY breaker panel cover replacement is extremely dangerous if certain precautions aren’t taken:

- The panel remains energized after shutting off main breaker.

- Arc flash or electrocution if contacting live bus bars and terminals.

- Short circuit risk if cover hits conductors or barriers are moved.

- Hazards are multiplied if working alone without oversight.

- Shock or electrocution from making wiring errors during installation.

With potentially fatal electric shock hazards present, DIY electrical work should only be attempted if following all safety rules and local laws. Unqualified persons should never remove or replace panel covers.

Code requirements for breaker panel covers

For a panel cover to comply with the NEC, CEC, and other electrical codes, it must meet certain requirements:

Material

Covers must be made of sturdy, fire-resistant insulating material capable of withstanding heat and arc flash temperatures. Common materials include:

- Plastic – UL 94V rated thermoplastic

- Galvanized steel – 20 gauge minimum thickness

- Aluminum – 18 gauge minimum thickness

Opening Size

Openings for breakers and cables must align with standard panel board openings. No unused openings are permitted.

Strength

Covers must be firmly secured to panel and strong enough to provide a barrier protecting from incidental contact.

Listing

All replacement covers should be tested and listed by a Nationally Recognized Testing Laboratory such as UL or ETL according to relevant product standards.

Covers that meet the above requirements provide protection, but only properly trained electricians should install or remove them.

How to install a breaker panel cover

Only a fully qualified and licensed electrician should tackle installing a new breaker panel cover. However, the general process involves:

- De-energizing the panel by switching off the main breaker and testing for power.

- Removing any existing old cover if present.

- Checking for damage, dirt, corrosion etc. inside the panel.

- Making sure the new cover aligns with breaker openings and bus stabs.

- Attaching the cover securely with all mounting screws or fasteners.

- Testing operation of all breakers and safety mechanisms.

- Re-energizing the panel once the cover is confirmed securely installed.

Safety gear like arc-rated clothing, insulating gloves, and electrical PPE should always be used when working on live panels. Follow all local building codes and OSHA regulations as well.

Conclusion

Proper breaker panel covers are absolutely vital to safety around electrical systems. By preventing contact with live parts, shielding against arcing hazards, and keeping debris out, covers provide essential protection as required by NEC, CEC, and other electrical codes. While only trained electricians should install or remove covers, homeowners can ensure covers are always securely in place. If a cover ever needs replacement or inspection behind it is needed, call a qualified electrician rather than attempting it yourself. Following basic safety rules and codes for electrical panel covers protects both people and property from potential electrical hazards.