Whether to install drip edge over or under roofing felt is a common question for homeowners and roofing contractors. The short answer is that drip edge should go over felt in most cases. However, there are some nuances to consider when deciding drip edge placement.

Page Contents

What is Drip Edge?

Drip edge is an L-shaped flashing that gets installed along the edges of the roof. It serves several important functions:

- It creates an overhang that allows water to drip clear of the roof edge and fascia.

- It covers the edges of the roof sheathing to protect it from rotting.

- It provides a finished look along the rakes and eaves.

Drip edge is typically made from galvanized steel or aluminum. It comes in 10 foot lengths that get overlapped and nailed into place along the roof edges.

What is Roofing Felt?

Roofing felt, also called tar paper, is a material made of recycled paper or fiberglass soaked in asphalt. It goes under shingles to add an extra waterproofing layer on the roof. The main functions of felt include:

- Creates a water-resistant barrier

- Offers secondary protection in case any shingles are damaged or lifted

- Helps smooth out small imperfections in the roof sheathing

Roofing felt typically comes in rolls of 36″ wide material. Most building codes require at least one layer of felt under asphalt shingles.

Drip Edge Over or Under Felt?

Installing drip edge under the felt leaves the bottom edge of the felt exposed. Any water that gets driven up by wind-driven rain could seep underneath and soak into the roof sheathing. Over time, this could lead to rot, mold growth, and leaks.

Installing drip edge on top of the felt provides extra protection. The metal flashing caps the bottom edge of the felt and diverts water into the gutter system. This prevents bulk water entry under the felt and shields the roof deck from moisture damage.

For these reasons, most roofing experts recommend installing drip edge over the felt in the majority of cases. The International Building Code and some shingle manufacturers specify that drip edge should go over roofing felt.

Exceptions Where Drip Edge Goes Under Felt

There are a couple exceptions where it may be preferable to place drip edge under roofing felt:

- On vulnerable roof pitches – Low slope roofs with a pitch less than 4:12 are more prone to leaks. The added protection of having drip edge under felt may be beneficial.

- In high wind regions – Coastal areas and other places with frequent high winds can drive rain up from underneath shingles. An underlayment sandwich provides robust protection.

- Under metal roofs – The flats of standing seam metal panels may benefit from having felt extend over drip edge.

In these situations, roofers may run the first course of felt over the drip edge to essentially “shingle” the flashing. The remaining courses of felt would be installed on top of drip edge as normal.

How to Install Drip Edge

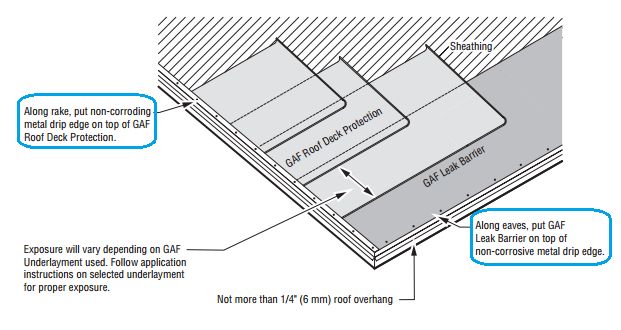

If you decide to place drip edge over roofing felt, the installation sequence would be:

- Install drip edge along the eaves (lower roof edge)

- Lay down eaves felt and overlap it over drip edge

- Install drip edge along rake edges

- Apply felt courses moving up the roof

- Install shingles over felt and drip edge

Proper drip edge installation requires nailing through the flanges into the roof deck. Use roofing nails or corrosion-resistant screws. Overlap pieces by 2-4 inches and caulk seams for optimal water protection.

Felt Underlayment Recommendations

When installing felt under asphalt shingles, synthetic underlayments are preferred by roofers today. The main options include:

- 30 lb. felt – Asphalt-saturated organic paper. Minimum code requirement.

- 15 lb. felt – Lighter synthetic fiberglass reinforced option.

- Peel-and-stick – Self-adhering rubberized underlayment. No fasteners needed.

- Ice & water barrier – Self-adhered membrane for leak protection in vulnerable areas.

Using a high-quality synthetic underlayment provides better traction during installation and can significantly extend the life of a roof compared to standard asphalt felt.

Benefits of Proper Drip Edge Installation

Taking the time to properly install drip edge over roofing felt provides numerous benefits:

- Enhanced protection from wind-driven rain leaks

- Prevents moisture from wicking up from underneath shingles

- Helps satisfy building code requirements

- Required for warranty coverage on some shingle products

- Creates a neat, finished look along roof edges

The small upfront cost of using quality drip edge and underlayments can pay dividends through improved roof performance and longevity.

Conclusion

While drip edge under felt may work fine in some cases, roofing experts overwhelmingly recommend installing drip edge on top of roofing felt. The additional leak protection provided by overlapping the metal flashing over felt is worth the minimal extra effort. Paying attention to proper underlayment installation details like drip edge placement can significantly extend the life expectancy of a roof.