A hot water recirculating pump is an important component of many home plumbing systems. It works by constantly circulating hot water through the pipes, so you don’t have to wait for hot water when turning on a faucet or shower. Over time, recirculating pumps can wear out or break down. But how do you know if your hot water pump needs to be replaced? Here are some signs that your recirculating pump may be failing.

Page Contents

- 0.1 Long wait times for hot water

- 0.2 Pump running constantly

- 0.3 Noisy operation

- 0.4 High energy bills

- 0.5 Burning smell

- 0.6 Leaking water

- 0.7 Reduced water pressure

- 1 What are the components of a hot water recirculating pump?

- 2 Common causes of hot water recirculating pump failure

- 3 Signs it’s time to replace your recirculating pump

- 4 Steps to replace a bad recirculating pump

- 5 How to maintain and extend pump life

- 6 Conclusion

Long wait times for hot water

The main purpose of a hot water recirculating pump is to provide instant hot water at the faucet. So if you find you’re having to wait 30 seconds or longer for hot water, that’s a clue the pump is not working properly. With a good pump, hot water should arrive in 10 seconds or less. The longer the wait, the more likely there is a problem with the pump.

Pump running constantly

Most recirculating pumps are designed to switch on every so often to circulate the hot water. This helps maintain the temperature. If you notice your pump is running non-stop, even when no faucets are open, that indicates a problem. The pump should not need to run continuously if it’s working correctly.

Noisy operation

You should barely notice a working hot water recirculating pump. But a failing pump can become loud with unusual noises like banging, grinding or squealing. If the pump noise is bothering you, it likely needs service or replacement.

High energy bills

Since recirculating pumps use electricity, a malfunctioning pump may drive up your energy costs. If your bills seem higher than normal, check the pump for signs of failure. A bad pump that runs constantly will waste a lot of electricity. Replacing it can potentially lower your bills.

Burning smell

In severe cases, an overloaded pump motor can actually burn out and start smoking. If you notice a burning odor coming from the vicinity of the water heater, the pump may be severely malfunctioning. Have it inspected right away to prevent a fire hazard.

Leaking water

The pump itself should not leak, but you may find water on the floor near the hot water heater and pump system. Leaks often indicate loose pipe fittings or an issue with the pump seals. Leaking water is a sign something needs to be repaired.

Reduced water pressure

If all your hot water faucets have lower pressure than normal, that points to a problem with water circulation. The pump may not be creating enough flow and pressure. Below average water pressure is usually a clear warning of a failing pump.

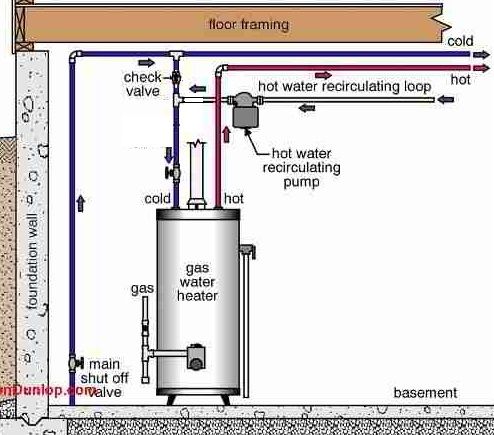

What are the components of a hot water recirculating pump?

To better understand how recirculating pumps work and what can go wrong, it helps to know the basic components:

Pump

This is the circulator unit that pushes hot water through the water lines and back to the water heater. Centrifugal pumps are most common. Problems here can involve broken motor, damaged impeller, worn bearings and more.

Timer

Controls when the pump turns on and off. Keeps the pump from running 24/7. Faulty timers will fail to switch the pump on and off as needed.

Flow check valve

Located between cold and hot water lines. Prevents backflow of water. Valve failure allows water to mix between hot and cold pipes.

Temperature sensor

Monitors water temperature. Signals the pump when to turn on to maintain hot water at a set temperature. Defective sensors give inaccurate readings.

Actuator valve

Opens and closes to allow water flow. Stuck valves can prevent circulation. Valve leaks can reduce pressure.

Check valve

Keeps water flowing one direction through the water heater and pipes. Worn check valves allow backflow.

Wiring

Connects the pump, controls and power supply. Loose or damaged wires can lead to electrical issues.

By understanding these components, you can better pinpoint where problems may arise in the pump system.

Common causes of hot water recirculating pump failure

Based on the pump components above, here are some of the most frequent causes of circulator pump problems:

Broken pump motor

Motors can overheat, short circuit or simply wear out over time. Signs include loud noise, burning smell or no operation. Requires pump replacement or motor rewinding.

Blocked or damaged impeller

Impeller fins break over time or get blocked by debris. Prevents proper water circulation. Usually requires new pump.

Leaking pump seal

Seal around the pump motor shaft wears out. Causes water leaks and allows air into the system. Requires new seal installation.

Defective timer

Timer fails to turn pump on/off automatically. Can cause constant operation. Requires timer replacement.

Clogged flow check valve

Scale, mineral deposits or debris block the check valve. Restricts water flow between hot and cold pipes. Valve needs cleaning or replacement.

Damaged temperature sensor

Cannot accurately monitor water temp. Pump runs incorrectly. Sensor needs calibration or replacement.

Stuck actuator valve

Does not open fully to allow water flow. Causes reduced pressure. May require valve replacement.

Leaking check valve

Allows hot and cold water to mix in pipes. Check valve needs replacement if it cannot seal tightly.

Electrical connection issues

Loose wiring connections can occur over time. Causes power loss to pump components. Wires need re-soldering or replacement.

Being aware of these common failure points can help you determine if your pump needs to be repaired or replaced.

Signs it’s time to replace your recirculating pump

While some pump problems can be repaired, there comes a point when replacement is the better option. Here are signs your recirculating pump is beyond repair:

– Pump is over 10 years old

– Loud noises like grinding or knocking

– Leaking water from pump housing

– Burning smells from pump motor

– Constant need to reset tripped circuit breakers

– Visible corrosion on pump components

– Only works intermittently, frequent breakdowns

Installing a new pump is recommended when you notice these more severe issues. At this stage, repairs may be complicated, risky and not worth the cost compared to replacement. It’s generally advised to replace circulator pumps after roughly 10 years.

Can I repair my recirculating pump?

Minor issues like leaking seals or stuck valves can potentially be repaired. But extensive repairs on the pump motor itself are often not worth it. In most cases, if the pump motor fails it’s easiest and most cost-effective to simply install a new pump unit. Only pumps with easily removed motors lend themselves to repair. It depends on the design and type of your existing pump.

Even with repairs, an older pump may break down again soon. Replacement ensures many more years of reliable service. When pricing repairs versus replacement, go with a new pump if the costs are comparable.

Steps to replace a bad recirculating pump

1. Turn off power and water supply to pump. Turn off circuit breaker and close water valves.

2. Drain any remaining water in pipes near pump. Open drain valve if available.

3. Disconnect water fittings and pipe unions around the pump. Have a bucket to catch water.

4. Unscrew pump mounting fasteners and remove pump.

5. Remove wiring connector from pump motor.

6. Install new pump in same orientation. Attach to piping and remount.

7. Reconnect wiring to pump motor. Verify tight connections.

8. Turn water supply back on and pressurize system. Check for leaks.

9. Turn power back on. Test new pump operation.

10. Flush lines until no air remains. Pump is ready for service.

Always follow pump manufacturer instructions for proper installation steps. Use pipe sealant on fittings and ensure mounting is secure. The process may vary depending on your setup. Hire a plumber if you’re uncertain how to replace the pump properly.

Recirculating pump replacement cost

For a typical 1/12 HP pump, expect to pay $150 to $300 for the pump itself. Labor and fittings will add $200 to $500 or more. Total costs can range from $350 up to around $800, depending on local rates and complexity. Get multiple quotes before choosing a plumber.

How to maintain and extend pump life

Proper maintenance helps recirculating pumps last longer. Here are some tips:

– Flush the pump periodically to clear sediment

– Keep all strainers and filters clean

– Fix any leaks promptly to prevent mineral buildup

– Lubricate motors and bearings yearly if accessible

– Tighten all electrical connections as needed

– Clean out the hot water tank regularly

A well maintained pump can operate for 15 years or longer before needing replacement. But if not maintained, pumps often fail sooner. Keep your system in top shape to maximize pump life.

Signs it’s time for water heater replacement

If your water heater is more than 10-15 years old, it’s likely time to replace the unit along with the pump. Signs you need a new water heater:

– Reduced hot water capacity

– Rust accumulating in tank

– Frequent need to relight pilot light

– Water leaks from tank fittings

– Loud rumbling or boiling noises

– Excessive mineral scale buildup inside tank

Replacing an aging, inefficient water heater provides an ideal time to install a new recirculating pump as well.

Conclusion

Identifying common signs of failure helps determine if it’s time to replace a problematic recirculating pump. While some pumps can operate reliably for 15 years, routine maintenance is required to maximize lifespan. If your pump is causing hot water issues, reference the troubleshooting tips here to decide whether repair or replacement is the right solution. With a properly functioning pump, you can enjoy consistent hot water delivery throughout your home.