An oil pressure gauge sensor is an important component in a vehicle’s engine that monitors oil pressure. The oil pressure sensor sends information to the gauge on the dashboard, allowing the driver to monitor oil pressure at all times. If oil pressure drops too low, it can cause severe engine damage, so having a properly functioning oil pressure sensor is critical.

Installing an oil pressure sensor is a relatively straightforward process that can typically be done in under an hour. With some basic mechanical skills and the right tools, many car owners can tackle this project themselves. In this article, we’ll walk through the full steps for installing an oil pressure gauge sensor.

Page Contents

What You’ll Need

Before starting the oil pressure sensor installation, you’ll want to make sure you have everything you need. Here are the basic supplies you’ll need:

- Replacement oil pressure sensor – Make sure to get the correct part number sensor for your specific vehicle’s make and model.

- Socket wrench and sockets – Usually a 3/8″ drive ratchet with metric sockets.

- Open end wrenches – Common sizes are 14mm, 17mm, 22mm which fit many sensor housing bolts.

- Shop rags – To clean up any oil drips or spills while working.

- Safety glasses – To protect your eyes from debris.

- Gloves – For hand protection when handling hot or sharp engine components.

- Clean funnel and engine oil – To refill the engine oil after installing the new sensor.

You may also need a repair manual for your specific vehicle, which will give you the proper procedure and bolts sizes needed. Make sure you have all the necessary tools and parts before starting.

Locating the Oil Pressure Sensor

The oil pressure sensor is usually located around the engine block, typically mounted somewhere in the crankcase. On many vehicles, the sensor screws into an oil passage hole in the block and has a wiring connector that sends a signal to the oil pressure gauge.

The specific location can vary depending on engine design, but some common sensor locations include:

- Near the oil filter housing.

- Mounted to the engine block behind the intake manifold.

- Behind the cylinder head on the back of the engine.

- Underneath the exhaust manifold.

Refer to a vehicle service manual or look up a diagram for your particular vehicle to find the exact oil pressure sensor location. Some disassembly may be needed to gain access to the sensor.

Removing the Old Sensor

Once you’ve located the oil pressure sensor, you can remove the old faulty unit:

- Make sure the engine is completely cool before starting. The sensor housing will be hot if the engine was recently running.

- Disconnect the negative battery cable to prevent electrical shorts while working.

- Locate the sensor connector wiring plug. Depress the connector clip and separate the plug from the sensor.

- Use a wrench to remove the retaining bolt holding the sensor housing in place. A socket wrench with an extension will usually provide the best access.

- Carefully unscrew the sensor housing and remove it from the engine block. Place a catch pan below it to collect any leaking oil.

- Inspect the sensor opening in the engine and clean off any debris, old oil, or gasket material.

Take care not to drop any hardware or sensor components into the engine when removing the old unit. Thoroughly clean the sensor mounting area on the block in preparation for installation.

Installing the New Oil Pressure Sensor

Once the old sensor is removed, you can install the new replacement pressure sensor:

- Check that the new sensor has the matching thread size to screw into the engine block opening. Confirm the proper orientation and depth as well.

- Apply a small amount of thread sealant to the sensor threads to help prevent leaks.

- Carefully thread in the new sensor by hand until snug.

- Use a wrench to tighten the sensor to the manufacturer’s torque specification, usually around 15-30 ft-lbs.

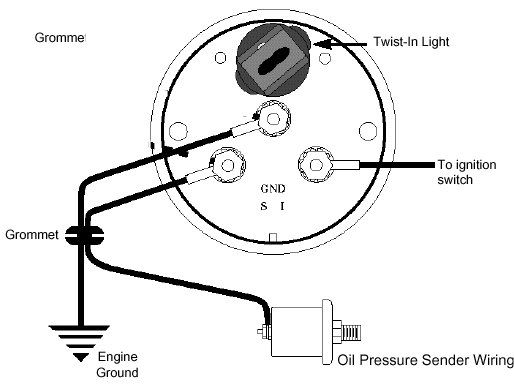

- Reconnect the wiring connector plug to the sensor.

- Check for any oil leaks at the sensor housing. Tighten further or reseal as needed until leaks are stopped.

- Replace any other components you removed to access the sensor area.

Take care not to over-tighten the sensor, as this can damage the housing or engine block. It’s also critical that no leaks are present, so double check your work.

Wrapping Up the Installation

Once the new oil pressure sensor is securely mounted, you can complete the installation:

- Reconnect the battery cable and turn the ignition on to test for proper gauge operation, but do not start the engine.

- Refill the engine with the specified type and quantity of new engine oil.

- Start the engine and let it run for 2-3 minutes while checking that the new sensor reading looks accurate.

- Turn off the engine and check for any leaks at the sensor housing. Re-tighten if any seepage is found.

- Allow engine to fully cool then check oil level and top off as needed.

- Properly dispose of your old oil and any waste.

The new oil pressure sensor should now be fully installed and functioning properly. Be sure to verify the reading looks accurate once the engine is warmed up and running. Check your work over thoroughly to confirm no leaks are present.

Troubleshooting Oil Pressure Sensor Problems

If you installed a new sensor but are still having issues, here are some troubleshooting tips:

- Double check for leaks – Sensor seals may not be fully tight allowing leaks.

- Inspect connections – Faulty wiring or connectors can cause issues.

- Test sensor output – Use a multimeter to check the sensor resistance range.

- Check gauge operation – Gauge may be damaged or need recalibration.

- Verify proper thread fit – Sensor may not be fully tightened down.

- Replace sensor with OE version – Aftermarket sensors can fit poorly or be defective.

Thoroughly going over your installation work can help identify any errors made that allow problems to persist.

When to Call a Professional Mechanic

While the oil pressure sensor is one of the easier DIY repairs on a vehicle, some circumstances do warrant leaving the work to professional auto technicians:

- Engine modifications – Sensor requirements change if engine internals are not stock.

- No access to lifts/tools – Overhead hoists and large socket sets allow for easier access.

- Extensive disassembly required – Taking apart major components should be left to professionals.

- Unfamiliar with procedures – Those new to auto repair are better off having a shop do the install.

- Diagnosing complex issues – Technicians can better pinpoint problems through testing.

- Physical limitations – Challenges reaching certain tight engine areas makes a shop the better choice.

If any of those scenarios fit your particular repair, the extra cost of having a professional mechanic take care of the pressure sensor installation may be worth the added convenience, accuracy, and safety.

Conclusion

Installing an oil pressure sensor is a fairly straightforward automotive DIY project. By having the proper tools, supplies, and access to accurate component torque specs, many vehicle owners can tackle this repair themselves in around an hour or less. Just take care when removing and installing the sensor by not overtightening, verifying no leaks, and rechecking your work. Troubleshoot any lingering issues through careful inspection and testing. While doable as a home mechanic job, more complex situations may warrant leaving the oil pressure sensor replacement to an experienced auto technician.