Measuring the bar length of a chainsaw is an important step in choosing the right chainsaw for your needs or maintaining your existing chainsaw. The bar length determines the maximum cutting capacity of the saw and affects maneuverability and ease of use. With some basic knowledge and simple tools, you can accurately measure your chainsaw’s bar length.

Page Contents

What the Bar Length Represents

The bar length of a chainsaw refers to the cutting bar that extends from the front of the chainsaw body and holds the saw chain. The bar provides rigidity and allows you to guide the chain during cutting. The numeric bar length measurement refers to the portion of the bar from the saw body to the tip of the bar, not including the rounded tip shape.

For example, if you have a chainsaw with an 18-inch bar length, the cutting bar extending from the saw body will measure approximately 18 inches long. However, the entire bar assembly from tip to tip may measure slightly longer due to the curve on the tip. The chain loops around the bar and will also be sized accordingly to match the bar length.

Typical Bar Lengths

Chain bar lengths typically range from 10 inches to over 30 inches on full-size chainsaws. The most common lengths are 14, 16, 18, and 20 inches. The larger the bar length, the more cutting capacity the saw has in a single pass. Here are some general bar length guidelines:

- 10-14 inches – Light duty such as limbing and pruning

- 16-18 inches – General purpose for most homeowners

- 20-24 inches – Professional use for felling trees and large cuts

- 26-32+ inches – Specialized professional saws for very large cuts

Factors in Choosing Bar Length

When selecting the right bar length, consider the types of tasks you’ll use the chainsaw for as well as your experience level:

- Intended use – Larger diameters need longer bars for cutting capacity

- Tree size – Felling small vs. large trees requires different reach

- Maneuverability – Shorter bars are more nimble in tight spots

- Operator strength – Ability to handle saw torque and weight

- Experience level – Start small if you’re a beginner

Measuring Methods

There are a couple of straightforward ways to accurately measure the cutting bar length on your chainsaw. Make sure the saw is turned off for safety.

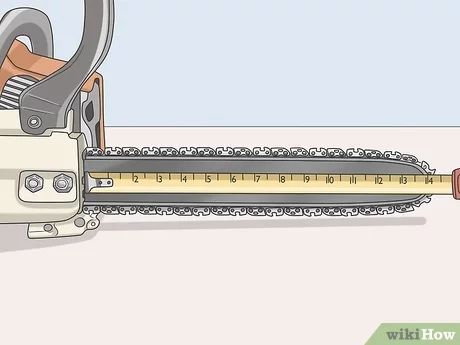

With a Measuring Tape

Using a cloth or metal measuring tape is the simplest way to measure bar length:

- Locate the bolts where the bar attaches to the saw body.

- Note where the bar curves up into the tip and straighten the tape in that area.

- Run the tape along the bottom of the bar from bolt to tip.

- Read the measurement at the tip to get your bar length.

Make sure to avoid any part of the chain or guide rails in your measurement. Press the tape flat along the bar for an accurate reading. Round your measurement to the nearest whole inch.

With a rigid ruler

For another simple option, use a steel ruler or straight edge:

- Lay the ruler flush against the bottom of the bar, starting at the saw body.

- Slide it out until you hit the tip of the bar.

- Read the measurement to get the length.

As with the tape, keep the ruler directly on the bar and avoid the chain. Make sure your ruler is entirely straight for accurate results.

Special Cases

On some chainsaw models, you may encounter special measurement considerations:

Extended Bars

Some bars can be extended with add-on sections to increase reach. Make sure to measure only the fixed portion of the bar itself and not any extensions.

Buried Nuts

On certain saws, the bar attachment nuts sit down in recessed pockets. For accurate results, measure from the outermost edge of the nut pocket rather than the nut itself.

Oregon PowerMatch Bars

Bars made by Oregon using the PowerMatch system have notches cut into the bottom of the bar. Avoid these notches when taking your measurement.

Replacing Bars

When replacing your chainsaw bar, you can use your measurement to find the correct replacement part:

- Refer to your saw manual for suitable bar lengths.

- Match the measured length as closely as possible.

- Many bars come in 2-inch increments (e.g. 16, 18, or 20 inches).

- If in between sizes, choose the next size up for capacity.

Also be sure your new bar matches the mounting pattern and gauge of chain for your particular saw model.

Maintenance Checks

In addition to selecting replacement and upgrade bars, measuring bar length periodically can assist with chainsaw maintenance:

- Stretching – A slightly longer measurement can indicate a stretched bar.

- Wear – Consistent use wears down bar length over time.

- Chain fit – Check that chain length matches bar length.

- Bolt tightness – Loose mounting bolts can affect bar length.

Catching small length changes early allows you to proactively replace stretched and worn bars before potential failure or saw damage occurs.

Cutting Capacity Table

As a quick reference, here is a table relating bar length to maximum cutting capacities:

| Bar Length | Max Cutting Diameter |

|---|---|

| 10″ | 8″ |

| 12″ | 10″ |

| 14″ | 12″ |

| 16″ | 14″ |

| 18″ | 16″ |

| 20″ | 18″ |

| 24″ | 22″ |

| 28″ | 26″ |

| 32″ | 30″ |

Factors Affecting Maximum Diameter

When estimating the maximum size you can cut, also consider:

- Wood type – Hardwoods require more cut capacity

- Cut technique – Felling vs bucking vs boring

- Bind in cut – Bar pinch due to wood pressure

- Saw power – Engine torque and HP rating

Leave a safety margin in your capacity estimates, never try to force a saw to cut at its absolute maximum limit.

Conclusion

Knowing the bar length of your chainsaw is key to choosing the right chainsaw for your needs. Measuring an existing bar is also useful for maintenance checks and identifying when to replace a worn or damaged bar. With basic tools and proper technique, you can easily measure bar length yourself. Match your saw’s capabilities to the cutting jobs at hand for optimal safety and performance.