Reading a chainsaw bar number is important for properly maintaining and operating your chainsaw. The bar number contains useful information about the bar’s size, mount type, gauge, and other specifications. Knowing how to decode a bar number will help you select the right replacement bar when needed.

Page Contents

What is a chainsaw bar?

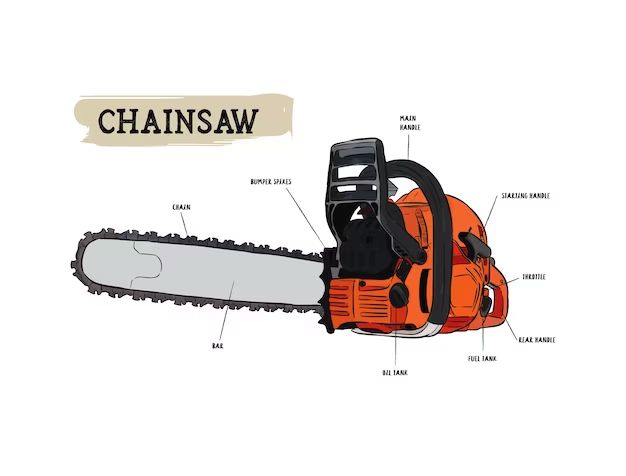

The bar is the long, toothed metal piece that supports and guides the saw chain on a chainsaw. Chainsaw bars come in different lengths, gauges, mount types, and profiles to fit different chainsaw models. The bar mounts to the chassis above the engine and uses the engine’s power to drive the chain around the bar to cut wood.

Parts of a chainsaw bar number

Chainsaw bar numbers are typically 18-20 digits long and contain several pieces of coded information. Here is an overview of the different parts of a typical bar number:

Mount type

The first 1-2 digits indicate the mount style that the bar is designed for. Common mount types include:

– 30 – Oregon 30 mount for smaller homeowner saws

– 50 – Oregon 50 mount for larger professional saws

– 51 – Oregon 51 mount found on older Homelite saws

– 55 – Oregon 55 mount on some larger Stihl saws

Gauge

The next 2 digits refer to the gauge, which is the thickness of the bar. Common gauge sizes are:

– 50 – 0.050″ gauge, for lighter duty saws

– 55 – 0.055″ gauge, also a lighter duty size

– 63 – 0.063″ gauge, the most common general purpose size

– 72 – 0.072″ gauge, used on high powered professional saws

Drive link count

The middle 4-5 digits indicate the number of drive links the bar contains. More drive links means a longer bar. A typical 16″ bar may have 50-55 drive links.

Bar profile numbers

The last 2 digits designate the nose sprocket type. Common profiles are:

– 10 – Standard bar nose found on most saws

– 11 – Sprocket nose bar for saws with a spur drive

– 15 – Sprocket nose for Stihl saws

– 18 – Hard nose for saws without a sprocket drive

Putting it all together

Now that you understand the different components, you can read complete chainsaw bar numbers. Here are two examples:

51ST024G72CK – Breaking this down:

– 51 – Older Homelite saw mount

– S – Special application bar

– T – 0.063″ gauge

– 024 – 24″ bar length

– G – Standard nose sprocket

– 72 – 0.072″ gauge drive links

– CK – Special chillers on rivets

3005 050463 27 – Breaking this down:

– 30 – Oregon 30 small saw mount

– 05 – 0.050″ gauge

– 050463 – 16″ bar length (50 drive links)

– 27 – Standard nose sprocket

As you can see, being able to interpret the bar number provides a lot of useful information about the bar’s specifications. This helps ensure you get an exact replacement bar when needed. Consult your saw’s owner’s manual bar recommendation if you are unsure about matching a replacement.

Why is reading the bar number important?

There are a few key reasons why it’s helpful to understand how to read your chainsaw bar number:

Get the right replacement

If your bar is damaged or worn out, you’ll need to replace it with one that exactly matches your saw’s requirements. The bar number has the details you need to find the right new bar.

Understand saw capabilities

The number signifies important specs like bar length, gauge, and nose type. This gives insight into the intended capabilities and limitations of that particular saw model.

Identify missing information

Sometimes key information like gauge and length are missing from the visible etchings on a worn bar. The number provides those details.

Order parts and accessories

You may need to purchase bar and chain oils, files, sprockets, or other parts that are specific to your bar’s characteristics. The number provides the details to get the right accessories.

Where to find the chainsaw bar number

The bar number is stamped or etched into the side of the bar near the powerhead. It may be quite small and hard to read if worn down over time. Here are some tips for finding it:

– Look near where the bar meets the saw chassis

– Angling the bar in sunlight can help make numbers more visible

– Remove the bar and chain and look closely with a flashlight

– Run your fingers across the surface to feel any raised lettering

– Trace the outline with chalk or graphite to highlight worn etchings

– Refer to your saw’s manual for the stock or recommended bar number

Some bars may only have a partial number stamped that doesn’t include all specifications. If the original number can’t be found, take measurements to determine the gauge, length, nose type, and mount style needed.

How to measure your chainsaw bar

If you can’t find any numbering on your bar or need additional measurements, use the following steps:

Step 1: Remove the bar and chain

This gives clear access to the bar for accurate measuring. Make sure the saw is off and cool before removing components.

Step 2: Measure overall bar length

Use a measuring tape to determine the total length from bar tip to the mount end in inches. Round up to the nearest whole inch.

Step 3: Count drive links

Physically count the number of drive links along the bar, which allows calculation of the precise bar length.

Step 4: Check gauge size

Use calipers to precisely measure bar thickness at the powerhead end to determine gauge. Compare to standard gauge sizes.

Step 5: Identify nose sprocket type

Note whether the nose has a sprocket, spur, or is just a plain hard nose.

Step 6: Determine mount style

Look at where the bar mounts to the saw chassis and compare to bar mount images to identify.

Finding replacement chain and bar

Once you know your bar’s specifications from the number or measurements, use that information to find a replacement bar and chain. Here are some tips:

– Search online using your saw model and bar number

– Check your saw’s owner’s manual for OEM part numbers

– Visit a saw shop with your bar – they can match measurements

– Stick to the same mount style, gauge, sprocket nose and length

– Match chain pitch to the sprocket nose

– Look for branding from reputable bar manufacturers

Be sure to get a complete bar and chain loop replacement for optimal performance. Breaking in the new bar and chain properly helps extend service life. Periodically filing and cleaning bars and chains also improves longevity.

Conclusion

Being able to accurately interpret chainsaw bar numbers enables you to get the right bar for your specific saw model. The number contains important details about bar mount, gauge, length, nose type, and other specifications that influence performance and safety. Measuring your bar and identifying key attributes provides the information needed if the number is unreadable. With the right replacement bar and matched chain loop installed, you can feel confident your saw will operate reliably. Knowing your saw’s capabilities and following operation, maintenance, and safety best practices allows you to take on any woodcutting job.