A pressure washer unloader valve can become stuck due to buildup of debris, corrosion, or wear over time. Unsticking the unloader valve is necessary to allow the pump to build pressure and operate normally. Here are the steps to safely unstick a stuck pressure washer unloader valve.

Page Contents

What is a Pressure Washer Unloader Valve?

The unloader valve on a pressure washer is a critical component that regulates water pressure in the high-pressure pump system. When the trigger on the spray wand is released, the unloader valve opens to allow water to circulate back to the pump inlet. This releases the high pressure and prevents the pump from being damaged by constant high pressure when not spraying.

The unloader valve is typically located on the discharge side of the pump and is connected to the high-pressure outlet. It has a spring-loaded valve mechanism that closes when the trigger is pressed, allowing full pressure to build up. When the trigger is released, the spring pushes the valve open so water recirculates internally.

Unloader Valve Components

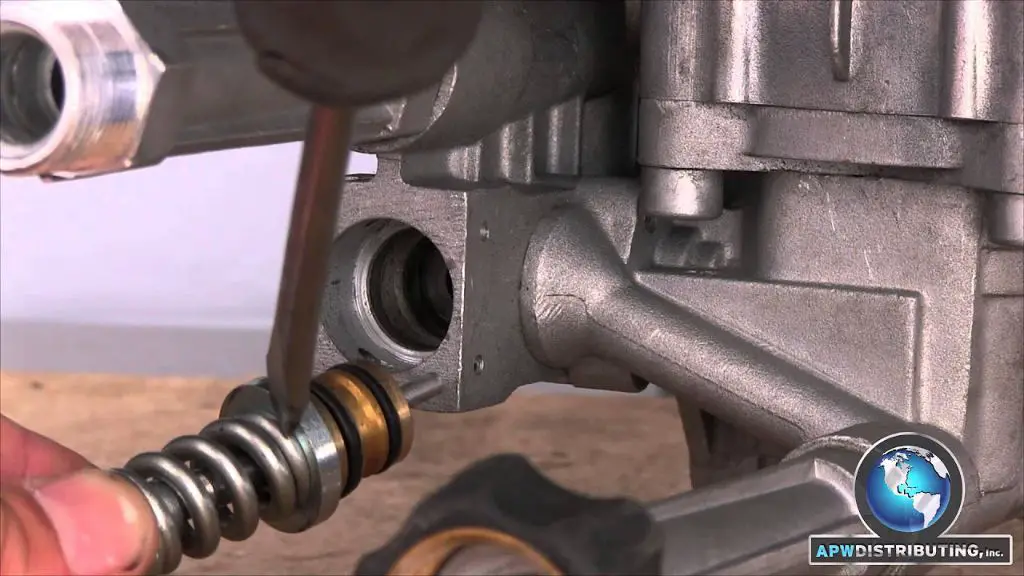

A basic unloader valve consists of the following components:

- Valve body – houses the valve components and channels the water flow

- Valve seal – seals the valve when closed to prevent water bypass

- Spring – provides force to open the valve when the trigger is released

- Valve stem – connects to the trigger mechanism and compress the spring when triggered

The valve body is mounted to the pump discharge port. When the trigger is pressed, the valve stem compresses the spring to close the valve. This allows full pump pressure to be directed through the hose and spray wand. Any issues with these components can cause the unloader valve to become stuck.

Causes of a Stuck Unloader Valve

There are several common reasons why a pressure washer unloader valve may become stuck closed or fail to open properly:

Debris Buildup

Over time, sediment and mineral deposits can accumulate inside the unloader valve body and on the valve components. Small stones, grit, and other debris in the water supply can become trapped and prevent the valve from seating properly or stick the moving components.

Corrosion

Corrosion due to aging, wear, or chemical reactions can cause rust, scale, and deterioration on the unloader valve components. Corroded surfaces may cause the spring to stick or bind and prevent smooth operation.

Wear and Damage

Normal use of the pressure washer causes wear on the valve parts. The valve seal can develop cracks or leaks, the spring can weaken and fail to open the valve, and rough surfaces can develop on the mating parts. Excessive pressure and overuse accelerates wear.

Misalignment

If the unloader valve is misaligned inside the valve body, it may bind against the inner walls or fail to seat correctly. Vibration or impact damage during use or improper installation can cause alignment issues.

Trigger Mechanism

Problems with the spray wand trigger mechanism, such as a weak or broken spring, can prevent the valve stem from moving properly. This leaves the unloader valve stuck closed.

Diagnosing a Stuck Unloader Valve

Before attempting to fix an unloader valve issue, diagnose the cause properly:

- Check for pressure buildup – Press the trigger on the spray wand. If pressure does not build, the unloader valve could be stuck open.

- Listen for bypass – With the trigger released, listen for water flowing back into the pump inlet. No bypass sound indicates the valve is closed.

- Inspect visually – Remove the unloader valve and check for debris buildup, corrosion, wear, and damage.

- Test function – Manually activate the valve stem and feel for smooth operation. The valve should open and close freely.

- Evaluate parts – Closely inspect the valve components for issues and test the spring tension. Worn or damaged parts will need replacement.

Pinpointing the exact problem will direct you to the proper repair method to get your pressure washer working again.

How to Unstick a Pressure Washer Unloader Valve

If you’ve diagnosed a stuck unloader valve, here are steps to unstick it and restore normal operation:

1. Disconnect Power

Before working on the unloader valve, always disconnect the pressure washer pump from its power source. This could be an electrical outlet, battery, or engine. Ensuring the system is depressurized and deactivated avoids dangerous high-pressure water discharge while servicing.

2. Access the Valve

Refer to your pressure washer manual for detailed directions on safely gaining access to the unloader valve. On most models, you’ll need to remove an access panel secured with screws or bolts. The valve is typically located on the discharge side of the pump.

3. Flush the Valve

Once accessible, flush the unloader valve with clean water to remove any built up debris inside the valve body or around components. You can use a garden hose aimed at the valve inlet and outlet ports.

4. Remove the Valve

Completely detach the unloader valve from the pump discharge port to allow further cleaning and inspection. This usually involves unscrewing a retaining nut securing the valve body. Cover the discharge port to prevent debris falling into the pump.

5. Descale and Clean

With the valve fully removed, clean all components to remove scale, corrosion, and debris buildup using a wire brush, scraper, and comprimed air if needed. Soak scaled parts in descaling solution or vinegar to break up mineral deposits.

6. Check Component Condition

Inspect valve parts closely for wear, cracks, or damage. Test the spring tension and valve seal. Any defective components should be replaced with OEM parts. An unloader valve rebuild kit is recommended.

7. Reassemble and Install

Lubricate o-rings with waterproof grease and reassemble valve components in the proper configuration. Refer to your owner’s manual exploded view diagram. Hand tighten only during reinstallation.

8. Test Operation

Reconnect pump power and water supply. Activate the trigger on the spray wand several times. The unloader valve should open and close properly, building and releasing pressure. If problems persist, repeat servicing steps to ensure components are clean and functional.

9. Complete Repairs

Confirm normal unloader valve operation by running the pressure washer through several complete cycles. Tighten any loose fittings to prevent leaks. Reinstall access panels and covers.

With proper servicing, a stuck unloader valve can usually be successfully unstuck and restored to working order. But repeat sticking or other performance issues indicate replacement may be needed.

When to Replace a Pressure Washer Unloader Valve

If an unloader valve remains stuck after thorough cleaning and troubleshooting, replacement is likely needed. Valves that exhibit the following issues typically require replacement:

- Stuck open or closed and not responding to cleaning

- External leaks around the valve body

- Visible cracks or damage on the valve body

- Worn or damaged internal valve components

- Weak or broken valve spring

Replacement unloader valves are readily available from pressure washer parts suppliers. Match the new valve to your model specifications for proper fit and performance. A valve rebuild kit is another option for fixing certain failures without fully replacing the valve.

Unloader Valve Maintenance Tips

Regular maintenance helps minimize unloader valve problems:

- Check and clear valve debris filters often

- Use water softener if hard water deposits are an issue

- Avoid running pump dry for extended time

- Winterize system properly for storage in freezing climates

- Lubricate o-rings and seals

- Follow manufacturer’s maintenance schedule

With attention to regular care procedures, your pressure washer unloader valve can enjoy maximum life span and trouble-free performance.

Conclusion

Stuck unloader valves are a common issue on pressure washers that prevents building of proper cleaning pressure. Typical causes include debris accumulation, corrosion, wear, misalignment, and problems with associated trigger components. Careful diagnosis of the specific problem is key to getting the unloader unstuck.

A combination of flushing, disassembly, cleaning, inspection, lubrication, reassembly, and testing steps will often get a stuck unloader valve functioning again. But valves with significant internal damage or component failures will need replacement. Following manufacturer maintenance recommendations helps minimize unloader valve problems.

With some basic mechanical skills and troubleshooting, an unresponsive pressure washer unloader valve can often be serviced and unstuck to extend the life of your pressure washer. But when replacement is needed, new or rebuild kit valves are readily available for most models.