Molding is used to accent walls, ceilings, windows, and doors in homes. Getting clean, accurate cuts when installing molding can be tricky without the right tools. A miter box is an indispensable tool that allows you to make precise angled cuts needed for installing molding.

Page Contents

- 1 What is a Miter Box?

- 2 Why Use a Miter Box?

- 3 Types of Miter Boxes

- 4 How to Use a Manual Miter Box

- 5 Cutting Various Angles

- 6 Cutting Long Moldings

- 7 Using a Compound Miter Saw Box

- 8 Using a Chop Saw Miter Box

- 9 Miter Box Tips and Tricks

- 10 Miter Box Maintenance

- 11 Troubleshooting Miter Box Issues

- 12 Safety Tips

- 13 Conclusion

What is a Miter Box?

A miter box is a guide that holds your molding at the proper angle while cutting. It has angled slots that align with common miter angles like 45 and 90 degrees. The slots guide your saw at the desired angle to make clean, accurate cuts.

Miter boxes are commonly made of plastic or wood. The slots are sized to fit standard hand saws or miter saw blades. Using a miter box ensures your molding will have neatly angled ends so it fits together properly.

Why Use a Miter Box?

There are a few key reasons to use a miter box when cutting molding:

- Allows accurate angled cuts. The guide slots ensure you cut at the right angle.

- Quick and easy to use. Just align the molding and make the cut.

- Versatile for cutting different angles. Most boxes have 45° and 90° slots.

- Portable to use anywhere. Doesn’t require any power source.

- Provides safety over freehand cutting. Keeps hands away from the blade.

- An inexpensive DIY tool. Can be purchased for $20 or less.

Without using a guide like a miter box, it’s quite difficult to cut accurate and consistent angles by hand. The miter box provides precision and repeatability for installing moldings and trims.

Types of Miter Boxes

There are a few common types of miter boxes:

Manual Miter Box

The most basic type is an all-manual miter box made of plastic or wood with designated slots for angled cutting. You slide the molding into the appropriate slot and cut with a hand saw. Manual miter boxes are inexpensive and don’t require any power.

Compound Miter Saw Box

This is a miter box designed specifically for compound miter saws. It holds the molding at adjustable angles while you make cuts with a powered miter saw. The angles can be adjusted more precisely compared to a manual box.

Chop Saw Miter Box

Some miter boxes accommodate chop saws. Chop saw miter boxes hold the molding vertically at an angle rather than horizontally. This allows the chop saw to cut through the edge of the molding at the desired angle.

How to Use a Manual Miter Box

Using a basic manual miter box only takes a few simple steps:

- Place the miter box on a flat, steady surface.

- Choose the appropriate slot for the desired angle. Most boxes have 45° and 90° slots.

- Insert the molding into the slot so it fits snugly against the back and bottom of the slot.

- Hold the molding firmly in place while cutting.

- Use a hand saw or backsaw to cut the molding following the angle of the slot.

- Make test cuts on scrap pieces first to check angles.

Position the molding so the saw blade enters the cutting slot at the far end. This helps provide blade clearance so you can make a complete cut. Apply steady pressure when cutting to keep the molding from shifting or vibrating.

Check that cuts fit properly by testing pieces before cutting your final molding length. Adjust the molding angle or position as needed until your test cuts are accurate.

Tips for Using a Manual Miter Box

Follow these tips when using a manual miter box:

- Make sure the molding fits snugly in the slot.

- Hold the molding firmly in place as you cut.

- Cut slowly and smoothly along the slot angle.

- Use a sharp fine-tooth backsaw or hand saw.

- Keep the miter box securely positioned.

- Check angles with test cuts first.

- Use a stop block to ensure consistent length cuts.

Cutting Various Angles

The most common miter slot angles are:

- 45° – Used for joining two mitered pieces at a 90° corner.

- 90° – Used for cutting ends perpendicular for butting against another piece.

- 60° – Used for hexagonal structures like gazebos.

- 22.5° – Used for octagonal structures like turrets.

Specialized miter boxes may include slots for compound angles. Make sure to position the molding correctly in the slot for the angle you need to cut.

45 Degree Miter Cuts

45° miter cuts are the most common for installing molding. Each end is cut at 45° to join at a 90° corner:

Position the molding vertically in the miter box aligned with the 45° slot. The two 45° angled ends will fit together cleanly.

90 Degree Cross Cuts

A 90° cross cut is used when you need to cut a straight end perpendicular to the length:

Align the end to be cut with the 90° slot. This creates a nice clean edge for butting against another perpendicular piece.

60 Degree Miters

60° miters create angles needed for hexagonal structures:

Each piece is cut at 60° on both ends. The six pieces then fit together to form a hexagon. A 60° slot is required to guide the cut.

22.5 Degree Miters

22.5° miters are used for octagonal structures like octagon gazebos:

Cut both ends at 22.5° using the appropriate miter slot. Eight pieces cut this way will form an octagonal shape.

Cutting Long Moldings

For longer molding pieces that don’t fit in the miter box, use stop blocks:

- Place a block at the inner end of the slot to stop the molding at the proper cutting position.

- Cut the first end of the molding.

- Reposition the block further out for the next cut length.

- Rotate the molding and cut the other end.

Stop blocks ensure each piece is cut to consistent lengths. Use pieces of wood cut to length or purchase stop block accessories made to work with your miter box.

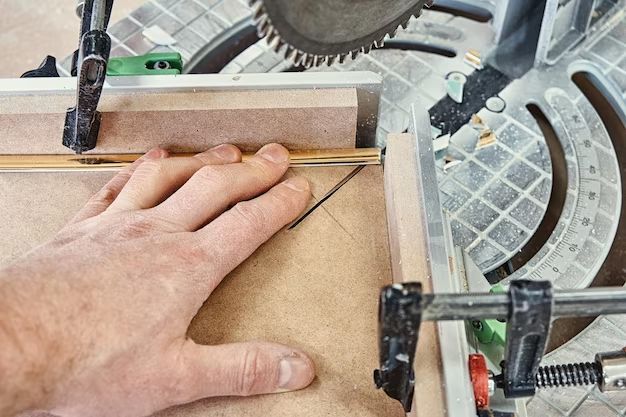

Using a Compound Miter Saw Box

Compound miter saw boxes provide more versatility than basic manual miter boxes. They allow you to dial in exact miter and bevel angles using the adjustments on a powered compound miter saw.

To use a compound miter box:

- Place the saw box securely on a flat surface.

- Lock the molding into the holding clamps at the desired position.

- Adjust the miter and bevel angles as needed.

- Support the molding near the cut.

- Make the cut using the miter saw.

- Check cut accuracy and adjust angles if needed.

The adjustable clamps hold the molding at the proper angle for the saw. Supports adjacent to the cut prevent vibration. Dialing in the perfect miter and bevel angles results in professional cuts.

Benefits of a Compound Miter Box

Compound miter saw boxes provide:

- Precise angle adjustment capabilities.

- Ability to set specific miter and bevel angles.

- versatility for various cutting needs.

- Heavy-duty steel construction for stability.

- Clamps to firmly hold molding while cutting.

- Compatibility with different miter saw brands.

The flexibility of setting the saw to any angles needed makes a compound miter box useful for crown molding, door and window trim, baseboards, and any decorative trim.

Using a Chop Saw Miter Box

Chop saw miter boxes are designed for use with chop saws. The molding is held vertically rather than horizontally:

The advantage of using a chop saw is the ability to cut through thicker molding and trim stock vertically versus cutting through the thin edge.

To use a chop saw miter box:

- Lock the vertical molding support at the desired angle using the angle adjustment knob.

- Tighten the hold down clamp around the molding to secure it.

- Support the end of the molding on the base plate.

- Line up the chop saw blade with the desired cut line.

- Make the angled cut through the edge of the molding.

Chop saw miter boxes allow you to quickly make vertical angled cuts through moldings up to 5 in. thick. The wooden support backing helps prevent tear-out on the backside of the cut.

Miter Box Tips and Tricks

Follow these tips when using a miter box to help ensure proper cutting and fitting of moldings:

Use Good Blade

The quality of cut directly impacts how accurately moldings fit together. Use a sharp fine-toothed backsaw or miter saw blade. 10-12 teeth per inch is a good range for smooth cuts.

Check Angles Before Cutting

Always cut a test piece out of scrap to verify the angle before cutting your final molding length. Adjust the miter box or saw angle slightly if needed to dial-in accuracy.

Secure Molding When Cutting

Make sure the molding is held tightly and cannot vibrate or twist. Apply firm downward pressure when cutting to prevent movement.

Support Near The Cut

Use a piece of wood to provide support against the bottom of the molding near the cut line. This prevents the cut end from breaking off due to weight.

Cut At Full Blade Depth

Allow the saw blade to cut fully through the molding thickness. Partial cuts will not fit well. Go slow for full cut depth.

Use Stop Blocks For Consistency

Position stop blocks in the miter box to ensure each piece gets cut to the same standardized length.

Clean Out Slots

Debris in the miter slot can throw off cutting accuracy. Use compressed air to periodically blow out dust and chips.

Miter Box Maintenance

Just a bit of regular maintenance keeps your miter box in good shape for years of use. Follow these miter box care tips:

- Check for debris before each use and clean slots as needed.

- Wipe down box with a damp cloth to remove dust and dirt.

- Use wax or silicone spray to lubricate slots.

- Inspect plastic boxes for cracks and replace if damaged.

- Sand dents out of wooden miter boxes.

- Replace any loose screws or hardware.

- Store miter box protected indoors when not in use.

Take a few minutes periodically to clean your miter box and keep the slots free of sawdust. This allows moldings to glide smoothly into position for the next project.

Troubleshooting Miter Box Issues

Having some problems getting perfect cuts? Here are solutions to common miter box cutting issues:

Gaps in Corners

- Verify miter angles with test cut pieces.

- Make sure molding sits tight to the slot bottom when cutting.

- Check for debris in the miter slot.

- Cut at full blade depth without tearing backside.

Uneven Cut Depth

- Apply firm downward pressure when cutting.

- Support molding near the cut to prevent teetering.

- Use a sharp blade for clean, even cuts.

- Slow down blade speed for hard woods.

Splintering or Rough Cuts

- Use a fine-tooth blade with at least 10 teeth per inch.

- Ensure blade is sharp and undamaged.

- Cut with smooth constant pressure.

- Apply painter’s tape to the cut line.

Crooked or Inaccurate Angles

- Check for twisted or warped miter slots.

- Make sure molding sits fully into slot when cutting.

- Clean debris from miter slots.

- Hold molding tight against slot as you cut.

Safety Tips

Always make safety a priority when using cutting tools:

- Wear eye protection to prevent debris from getting in your eyes.

- Use saw guards and keep hands away from the blade.

- Unplug power tools before adjusting or making repairs.

- Don’t force cuts – go at proper blade speed for material.

- Make sure work area is free of clutter and trip hazards.

- Follow all manufacturer safety instructions.

Be mindful of where your hands are positioned in relation to the blade. Never reach across or near the blade while it is moving. Stay focused and never cut when tired or rushed.

Conclusion

A miter box is an essential tool for trim carpentry. It allows you to make clean precise angled cuts needed for installing molding and creating professional looking finished products. Investing in a good miter box saves time, frustration, and waste when cutting moldings.

There are several types of miter boxes available to suit different cutting needs. A basic manual miter box works well for small jobs. Larger compound and chop saw boxes provide versatility for more heavy-duty molding projects. Set up and learn how to use a miter box properly before your next trim carpentry project.