A recirculating pump on a water heater helps provide hot water more quickly when a hot water tap is opened. It works by circulating water between the water heater and the fixtures needing hot water. This allows hot water to be immediately available at the tap, without having to wait for cold water sitting in the pipes to flow out first. Understanding how recirculating pumps work can help with proper installation, settings adjustments and troubleshooting.

Page Contents

What is a recirculating pump?

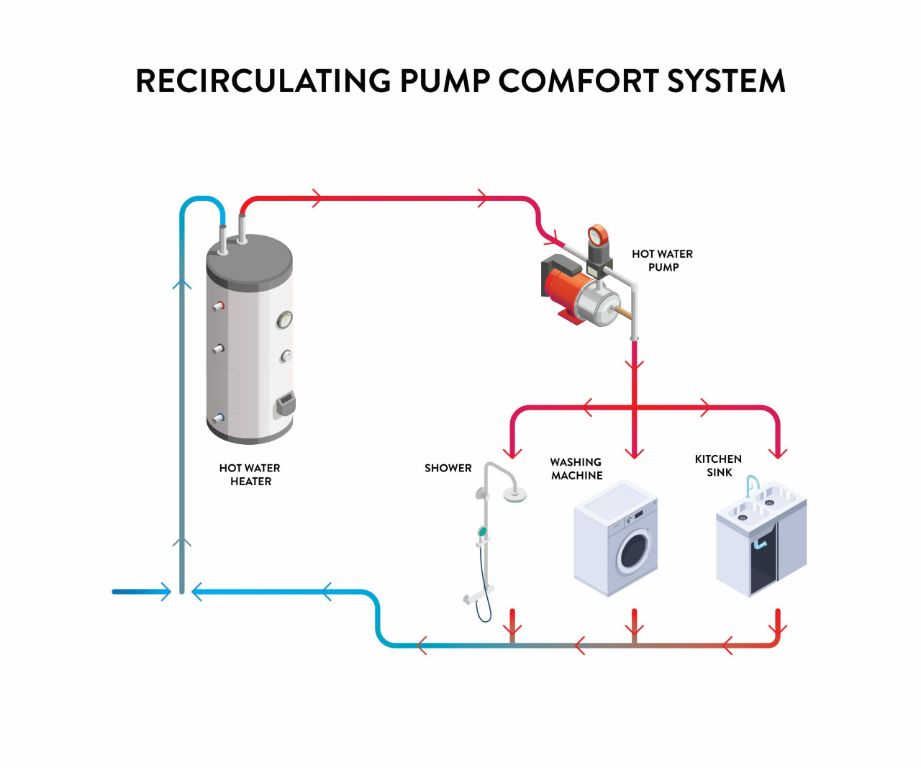

A recirculating pump is a small pump that gets installed on the hot water plumbing system. It is connected to the hot water line near the water heater on one side, and to the hot water line going back to the fixtures needing hot water on the other side. When the pump runs, it circulates hot water from the water heater through the hot water plumbing and back again in a loop. This keeps hot water circulating near all the hot water fixtures, eliminating the cold water sitting in the pipes that must be purged before hot water can flow when a tap is first opened. The pump may run on a timer or use a sensor to determine when hot water is being used.

Recirculating pump system components

A basic recirculating pump system consists of:

- Small pump – Usually under 1/12 horsepower and rated for potable water.

- Recirculation line – Dedicated hot water line completing the loop back to the water heater.

- Check valve – Lets water flow only in one direction in the loop.

- Aquastat – Controls the pump based on water temperature.

- Timer – Can be used instead of or with an Aquastat for pump control.

- Return line – Small line connecting pump back to water heater.

Optional accessories include things like an electronic controller, thermostatic valves, cycle stop valves and unions for simplifying installation and service.

How does a recirculating pump provide instant hot water?

When the recirculating pump runs, it takes hot water from the hot water pipes near the water heater and pumps it through the recirculation line and back to the water heater storage tank. This creates a continuous loop of hot water flow. The hot water loop allows hot water to be “pre-staged” near any hot water fixtures, eliminating the wait for cold water sitting in the pipes to be flushed out. Opening the hot water tap provides an immediate flow of hot water that was already circulating nearby.

Recirculating pump operation

Understanding how a recirculating pump works involves looking at the flow path it creates and how it gets controlled.

Recirculating loop flow

When the recirculating pump turns on, it takes suction from the hot water line near the water heater. It pumps through a dedicated return line, also called a recirculation line. This line makes a loop throughout the hot water plumbing system, returning back to the water heater. A check valve in the return line ensures water flows in only one direction through the loop.

As hot water is pumped through the loop, cold water sitting in the pipes gets displaced. This hot water remains near fixtures, so when a hot water tap is opened, hot water is readily available. The recirculation line is insulated to help minimize heat loss as the hot water flows through it repeatedly.

Pump control settings

For the recirculating pump system to work properly, the pump needs to run on a setting that activates it when needed, but doesn’t allow it to run constantly. This is achieved through temperature and/or timer based controls. Here are some common options:

- Aquastat – Turns pump on based on low return water temperature. Turns it off when water reaches desired temp.

- Timer – Runs pump on a set schedule during times hot water is typically used.

- Timer with Aquastat – Timer activates pump during set times. Aquastat turns pump off when loop reaches proper temperature.

- Demand control – Sensor at fixture detects when hot water is running. Activates pump as needed.

The best setting depends on the household’s hot water usage patterns. Timers and aquastats are commonly used for their simplicity and low cost. More advanced demand controls can maximize efficiency but have a higher initial cost.

Recirculating pump installation

Proper installation is important for a recirculating pump system to function effectively. Here are some key steps:

Mounting the pump

The recirculating pump must be installed on the hot water line near the water heater. It often gets mounted on the wall within several feet of the heater. The pump should be installed according to manufacturer instructions, following all applicable plumbing codes.

Connecting plumbing

The pump connects to the hot water line through two connections:

- Suction line – Leading from hot water line to pump inlet

- Return line – Leading from pump outlet back to water heater

These lines need to be properly sized and oriented according to the pump specifications. A check valve is installed on the return line to prevent backflow. The plumbing must be insulated to reduce heat loss.

Wiring

The pump motor requires an electrical connection. This is wired to a control like an aquastat or timer. Power may come from the water heater circuit or a separate pump circuit. Low voltage controls make wiring easier. All electrical work must be done per local codes.

Settings

Once installed, the pump and controls need to be adjusted for proper operation. This includes setting clock timers and the aquastat activation temperature. Settings may need adjustment over time for maximum efficiency.

Recirculating pump troubleshooting

Some common recirculating pump issues and troubleshooting techniques include:

Pump not running

- Check circuit breaker or fuse

- Inspect pump wiring connections

- Test outlet for power with multimeter

- Press reset button on motor

- Replace bad motor capacitor

Pump runs constantly

- Adjust aquastat to higher temperature

- Check aquastat wiring

- Replace faulty aquastat

- Repair stuck check valve

- Ensure proper water flow

Noisy pump operation

- Tighten mounting and plumbing connections

- Clear blockages affecting water flow

- Ensure no air bubbles are present

- Replace worn pump impeller

Insufficient hot water

- Check for cold water crossovers in plumbing

- Increase aquastat temperature setting

- Modify timer settings to match usage

- Repair leaks allowing heat loss

- Insulate exposed plumbing

No hot water at fixtures

- Check recirculation line valves are open

- Inspect for obstructions or kinks in lines

- Repair leaks or breaks in plumbing

- Replace faulty check valve

- Purge air trapped in plumbing

Benefits of a recirculating pump

Here are some benefits that a properly operating recirculating pump can provide:

- Faster hot water delivery – Eliminates wasted time waiting for hot water

- Water savings – Avoid running tap to waste cold water while waiting for hot

- Energy savings – Less heat loss from water sitting in pipes constantly

- Convenience – Hot water readily available when needed

- Versatility – Can be used with any water heater fuel type

- Comfort – Enjoys benefits of instant hot water

Conclusion

Installing a recirculating pump is a comfort and efficiency improving upgrade for any water heating system. It saves time, water and energy by providing instant hot water at every hot water tap. Understanding how recirculating pumps work and properly installing them allows homeowners to enjoy the full benefits.