A trip lever drain stopper is a type of drain stopper that is opened and closed by a lever mounted on the tub or sink. When the lever is lifted up, it pulls on a linkage that lifts the stopper up to allow water to drain. Lowering the lever pushes the linkage down to seal off the drain again.

Page Contents

- 1 What is a Trip Lever Drain Stopper?

- 2 How Does the Trip Lever Mechanism Work?

- 3 Types of Trip Lever Mechanisms

- 4 Materials Used in Trip Lever Mechanisms

- 5 Different Designs of Trip Lever Stoppers

- 6 Advantages of Trip Lever Drain Stoppers

- 7 Disadvantages of Trip Lever Drains

- 8 How to Install a Trip Lever Drain Assembly

- 9 How to Repair a Trip Lever Drain

- 10 Conclusion

What is a Trip Lever Drain Stopper?

A trip lever drain stopper consists of several components:

- Lever – The lever is mounted on the tub or sink deck. It is connected to the linkage.

- Linkage – The linkage connects the lever to the pivot rod. It converts the up/down motion of the lever into vertical motion to raise and lower the stopper.

- Pivot rod – The pivot rod runs vertically down into the drain pipe. It is attached to the stopper and lifts it up when pulled upwards by the linkage.

- Stopper – The stopper seals off the drain opening. It has a gasket or seal that makes contact with the drain flange when closed.

- Tailpiece – The tailpiece is a short length of pipe that the stopper assembly mounts to. It connects to the drain pipe.

Lifting the trip lever pulls the linkage up, which pulls the pivot rod and stopper up to open the drain. Lowering the lever reverses the motion to seal the stopper back over the drain opening. The linkage provides a mechanical advantage that allows the stopper to be operated with minimal effort.

How Does the Trip Lever Mechanism Work?

Here are the steps involved in operating a trip lever drain stopper:

- The lever is lifted up from the tub or sink deck. It pivots up on a fulcrum or hinge point.

- As the lever lifts, it pulls on the linkage. The linkage is connected to the lever’s arm and to the pivot rod.

- The linkage pulls the pivot rod up vertically. The pivot rod runs down through the tailpiece into the drain pipe.

- The stopper is connected to the bottom of the pivot rod. As the pivot rod travels up, it pulls the stopper up off the drain opening.

- With the stopper open, water can now drain freely down the tailpiece and out the drain pipe.

- To close the drain, the lever is lowered back down. This pushes the linkage down.

- The linkage pushes the pivot rod back down into the tailpiece, which lowers the stopper back over the drain opening.

- The stopper seals against the drain flange, preventing any more water from draining out.

The linkage mechanism allows the up/down motion of the lever to be transmitted to the pivot rod. The linkage gives the lever a mechanical advantage, allowing the stopper to be raised and lowered easily by lifting or lowering the lever.

Types of Trip Lever Mechanisms

There are a few different types of trip lever mechanisms:

Bell Crank Lever

This uses a bell crank linkage. The lever attaches to one end of a pivoting bell crank. The other end of the bell crank attaches to the pivot rod. As the lever is lifted, it rotates the bell crank to pull up the pivot rod.

Swing Arm Lever

The lever is attached to a swing arm that pivots at one end. The other end of the swing arm connects to the pivot rod. Lifting the lever rotates the swing arm in an arc to pull up on the pivot rod.

Direct Pull Lever

In this design, the pivot rod extends up into the lever. Lifting the lever pulls directly on the pivot rod without any intermediate linkage.

Push Button Lever

Pushing down on a button depresses the pivot rod to open the stopper. The button is on the end of a lever arm above the pivot rod.

Materials Used in Trip Lever Mechanisms

- Lever – Usually plastic, metal, or ceramic.

- Linkage – Metal rods and swing arms.

- Pivot rod – Stainless steel, copper, or plastic rod.

- Stopper – Rubber, plastic, or silicone stopper.

- Drain flange – Metal or plastic flange that stopper seals against.

The materials must withstand constant exposure to water without corroding over time. Lifting mechanisms are designed to operate smoothly and not get stuck or corroded.

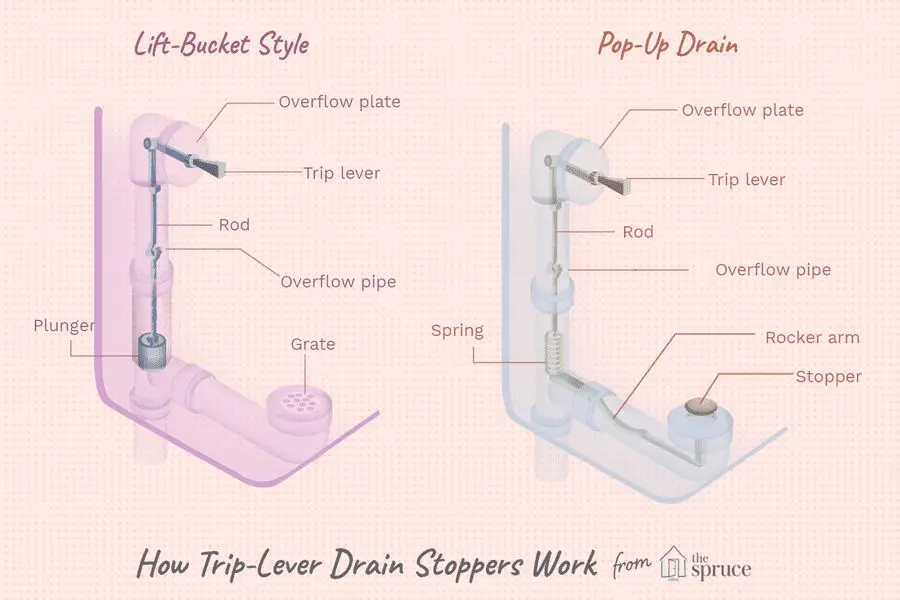

Different Designs of Trip Lever Stoppers

There are a few common trip lever designs:

Lift and Turn Stopper

Lifting the lever raises the stopper. Turning the lever locks it in the open position. Turning it back allows the stopper to close.

Foot Lock Stopper

A pedal-like lever near the floor locks the stopper open hands-free. Stepping on it again releases the stopper.

Push Button Stopper

Pushing a button opens and closes the stopper. The button can be mounted on the tub deck or wall.

Toe-Touch Stopper

A large lever is activated by tapping it with the toe to open or close the drain.

Pop-Up Stopper

On vessel sinks, a pop-up rod raises the stopper up through the sink drain hole to open it.

Advantages of Trip Lever Drain Stoppers

Trip lever drains have some advantages over other types:

- Easy to operate – Just lift the convenient lever to open and close.

- Fast draining – Raises stopper high for full drainage.

- Adjustable – Stopper seal height is adjustable on some models.

- Reliable – Linkage provides consistent operation over years of use.

- Hidden construction – Linkage is concealed under the tub or sink.

- Hands-free models – Allow stopper to be opened/closed without using hands.

- Smooth control – Lever provides smooth operation and control over drainage.

The lever mechanism provides an effortless way to reliably control water flow without having to manually engage the stopper. Hands-free options allow added convenience.

Disadvantages of Trip Lever Drains

Some potential downsides of trip lever drains include:

- More difficult installation – Requires access below the sink/tub to install linkage.

- More parts – Added linkage pieces can fail over time.

- Not universal – Many cannot be installed on old or unusual drain configurations.

- Stopper may not fully close – The lever does not seal the stopper like a manual stopper.

- No overflow option – Unlike some pop-up assemblies, trip levers lack an overflow outlet.

- Can’t be fully disassembled – Linkage prevents removing all parts for cleaning.

- Corrosion – Exposed linkage can corrode over time and fail.

While trip lever mechanisms provide hands-free convenience, the added linkage means they may not work in all drain configurations. The lack of an overflow and greater difficulty fully disassembling for cleaning are other disadvantages for some homeowners.

How to Install a Trip Lever Drain Assembly

Follow these basic steps to install a trip lever drain:

- Remove old drain – Disconnect and remove existing drain stopper and flange from sink or tub.

- Clean drain – Remove old plumber’s putty from drain hole and clean surfaces thoroughly.

- Dry fit parts – Test fit new drain flange and trip lever assembly to ensure proper fit.

- Apply putty – Apply plumber’s putty around underside of new drain flange.

- Install flange – Press flange into drain hole firmly to seal putty beneath.

- Tighten nut – Tighten retaining nut from below to hold flange in place.

- Install tailpiece – Screw new tailpiece with stopper onto drain body protruding below.

- Connect linkage – Attach bell crank or swing arm linkage pieces to tailpiece and lever.

- Adjust stopper – Test operation and adjust stopper seal height as needed.

Always follow manufacturer’s specific instructions for your model. Use silicone sealant instead of plumber’s putty if installing on a marble, granite, or other delicate sink. Take care not to damage porcelain enamel surfaces while working underneath.

How to Repair a Trip Lever Drain

Trip lever drains may need occasional repairs. Here are some steps for diagnosing and fixing common issues:

Loose Stopper Seal

- Tighten pivot rod nut or adjust stopper cam to raise stopper height.

- Replace worn or cracked stopper if damaged.

Leaking Around Flange

- Tighten flange retaining nut from below.

- Seal with new plumber’s putty if loose or cracked.

- Replace flange if damaged or leaking continues.

Slow/Clogged Drain

- Remove stopper and clean out drain pipe.

- Clear debris or hair tangled around stopper seal.

- Use drain cleaning tool to clear clog below stopper.

Stopper Sticking

- Lubricate pivot rod and linkage with silicone spray.

- Replace corroded or jammed components.

- Adjust bent linkage stopping normal operation.

Loose Lever

- Tighten lever retaining screw to secure it.

- Replace stripped lever threads with new lever.

Consult manufacturer instructions for your specific model to troubleshoot other issues. Drain stoppers should provide years of smooth, reliable performance when properly maintained.

Conclusion

Trip lever drain stoppers provide a convenient hands-free way to operate a sink or tub drain stopper. The lever connects to a linkage mechanism that smoothly raises and lowers a stopper to seal or open the drain. Different styles are available, but all allow reliable drainage control via a simple lift of the lever. With proper installation and periodic maintenance, a trip lever drain can provide years of trouble-free use. The lever allows effortless drain control while keeping moving parts hidden from view for a clean look. For most bathrooms, the benefits of a trip lever’s easy operation outweigh the minor potential downsides.