Properly lubricating the wheel bearings on your boat trailer is essential to protect them from wear and tear. Greasing the bearings regularly can help prevent premature failure, extend the life of the bearings, and avoid costly repairs down the road.

Page Contents

- 1 What are boat trailer wheel bearings?

- 2 Why is proper lubrication important?

- 3 How often should you repack trailer wheel bearings?

- 4 How do you repack trailer wheel bearings?

- 5 Tips for repacking trailer wheel bearings

- 6 Bearing Buddies

- 7 When to seek professional help

- 8 Frequently Asked Questions

- 8.1 What type of grease should be used on boat trailer wheel bearings?

- 8.2 How can you tell if trailer wheel bearings need to be repacked?

- 8.3 Is it okay to mix different brands or types of grease when repacking bearings?

- 8.4 Should you rotate boat trailer tires?

- 8.5 How can you avoid boat trailer bearing failure while traveling?

- 8.6 Why do boat trailer bearings fail in saltwater?

- 8.7 Can you pack wheel bearings by hand?

- 8.8 How tight should a boat trailer wheel bearing be?

- 9 Conclusion

What are boat trailer wheel bearings?

Boat trailer wheel bearings are sets of steel balls or tapered rollers contained in a metal housing that allow the trailer’s wheels to spin freely along the axle. The bearings are lubricated to reduce friction and enable smooth rotation under the weight of the trailer and boat.

Most boat trailer wheel bearings typically utilize tapered roller bearings. Tapered roller bearings are designed to handle both radial and thrust loads exerted by the weight of the trailer. Other types of bearings used include ball bearings and roller bearings.

Why is proper lubrication important?

Greasing the wheel bearings at regular intervals is vital to prevent wear and tear as the bearings roll over the axle thousands of times. The lubricant helps reduce friction and heat buildup while protecting against corrosion. Without adequate lubrication, the steel balls or tapered rollers would grind against the metal housing causing the bearings to fail prematurely.

The most common cause of a failed boat trailer wheel bearing is insufficient or improper grease. Lack of lubrication leads to excess friction, which can cause the bearings to overheat. The grease breaks down when overheated and no longer properly cushions the bearings. This can eventually lead to bearing wear, loss of structural integrity, and bearing failure.

How often should you repack trailer wheel bearings?

Most manufacturers recommend repacking boat trailer wheel bearings at least once a year or every 12,000 miles. However, the frequency depends on several factors:

- Type of use – If the trailer is used in saltwater, bearings should be repacked more frequently, as often as every 3 months. Saltwater is very corrosive and can contaminate and degrade the grease quickly.

- Mileage – Bearings on boat trailers that are hauled long distances need maintenance more often than those used locally.

- Road conditions – Rough, bumpy roads can cause more vibration and accelerate wear on bearings.

- Load – Larger, heavier boats put more strain on the bearings and require more frequent repacking.

- Maintenance history – If the bearings have been poorly maintained, they would need attention more frequently.

You should inspect the bearings regularly and look for signs they need service, such as excessive noise or looseness when the wheel is spun. Any hint of trouble means don’t wait – repack the bearings immediately.

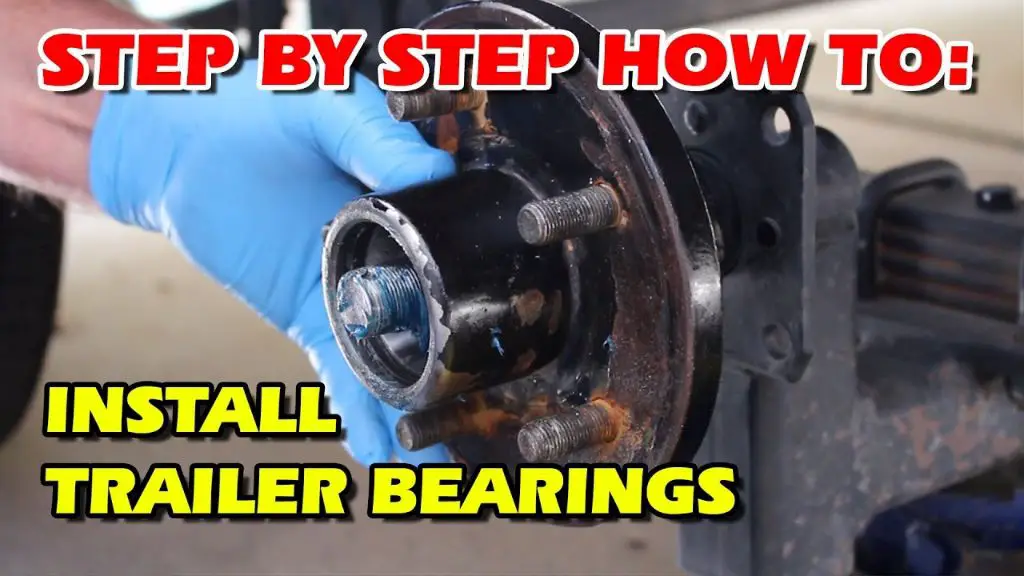

How do you repack trailer wheel bearings?

Here are the basic steps to safely repack boat trailer wheel bearings:

- Jack up the trailer and secure it on jack stands.

- Remove the hubcap, cotter pin, spindle nut and washers.

- Pull the hub assembly off the spindle.

- Thoroughly clean all old lubricant from the hub and bearings using solvent or kerosene.

- Inspect the bearings, races, and seals for any signs of wear, pitting, or damage. Replace any questionable parts.

- Pack the bearings by forcibly pressing fresh grease into the cavities between the roller balls or tapered rollers.

- Install the inner bearing into the hub and then pack the outer bearing.

- Place the grease-packed outer bearing into the hub.

- Install the bearing seal or retainer.

- Put the hub assembly back onto the spindle and replace the washers and spindle nut.

- Tighten the spindle nut just to the point where the hub has no free play, but still spins freely.

- Replace the cotter pin through the spindle nut and bend the ends over.

- Replace the hubcap.

- Repeat the process for the other wheel hub.

- Lower the trailer and test that the wheels spin freely without wobbling.

Be sure to use a high-quality marine-grade trailer wheel bearing grease. Look for a water-resistant formulation made specifically for boat trailer applications. Never use automotive chassis grease or standard multi-purpose grease.

Tips for repacking trailer wheel bearings

- Work in a clean area to avoid contaminating the bearings and grease.

- Always repack both the inner and outer bearings as a set, even if only one side’s hub is removed.

- Pack plenty of grease into the cavities between the bearing balls/rollers. Press new grease in until it oozes out the sides.

- Avoid spinning the bearings during packing, which can damage the grease matrix.

- Make sure to reinstall bearings, races, seals, etc. in the correct direction and orientation.

- Don’t overtighten the spindle nut – it only needs to be just snug enough to remove wheel wobble.

- Rotate tires and check tires pressures while performing bearing maintenance.

Bearing Buddies

Some boat trailers use a grease fitting device called a Bearing Buddy to allow quick, no-mess re-lubrication of bearings. A small plastic chamber is installed on the hub in place of one bearing seal. This chamber has a spring-loaded rubber piston that presses against the bearing. A grease zerk fitting allows fresh grease to be pumped into the chamber where it presses through the piston to replenish the bearing.

Bearing Buddies make it convenient to periodically add small amounts of grease while on the road. Just a shot or two is needed to freshen the lubrication. However, the chamber needs to be disassembled and bearings fully repacked at least annually.

When to seek professional help

While DIY bearing repacking can save money compared to taking the trailer to a repair shop, don’t hesitate to seek professional assistance if:

- You don’t feel fully comfortable with the repacking procedure

- You don’t have the necessary tools and jack stands

- The hub and bearings are stuck from corrosion or damage

- The races are damaged and need to be replaced

- The trailer has been immersed in saltwater

- There are any signs of abnormal wear or damage upon inspection

A professional mechanic has the expertise and equipment to thoroughly inspect the bearings, races, seals, and hub components. They can catch small issues before they become big problems and perform necessary repairs. Periodic pro maintenance and repacking of your boat trailer wheel bearings gives peace of mind for safety on the road.

Frequently Asked Questions

What type of grease should be used on boat trailer wheel bearings?

Always use a high-quality marine trailer wheel bearing grease designed specifically for boat trailer applications. Look for lithium complex or calcium sulfonate greases that provide excellent water resistance.

How can you tell if trailer wheel bearings need to be repacked?

Signs that the bearings need fresh grease include excessive noise when spinning the wheels, looseness or play when rocking the tire, overheating hubs, leaking or damaged seals, corrosion, and degraded or discolored grease.

Is it okay to mix different brands or types of grease when repacking bearings?

No, it is best to completely clean out old grease and use only fresh grease of the recommended type. Mixing grease chemistries could lead to breakdowns or failure.

Should you rotate boat trailer tires?

Yes, rotating the tires when repacking the bearings helps promote more even wear. Swap the left tires to the right side and vice versa.

How can you avoid boat trailer bearing failure while traveling?

Check hubs for abnormal heat after the first few miles of towing. Pulll over immediately if a hub feels hotter than normal. Let hubs cool completely before continuing. Make extra stops to give the bearings a rest on long hauls.

Why do boat trailer bearings fail in saltwater?

Saltwater is extremely corrosive and contaminates grease rapidly. Frequent washing, more frequent repacking, and using water-resistant marine grease can help combat saltwater damage.

Can you pack wheel bearings by hand?

Yes, but using a bearing packing tool makes the job easier, cleaner and more thorough. The tool presses grease deep inside the bearing.

How tight should a boat trailer wheel bearing be?

The spindle nut only needs to be tight enough to remove any play or wobble in the wheel hub. Over-tightening can damage bearings. Rotate the wheel while tightening the nut in small increments.

Conclusion

Proper lubrication is essential to keep boat trailer wheel bearings operating smoothly and prevent premature wear. Repacking the bearings annually or every 12,000 miles is recommended, along with more frequent maintenance if hauling in saltwater. Watch for warning signs like noise, looseness, or overheating hubs to indicate when fresh grease is needed. Take care to thoroughly clean old grease and properly reassemble components. Consider having a professional mechanic service the bearings if you are uncomfortable with the DIY process. Keeping up with routine repacking, inspection, and maintenance will extend the life of your trailer wheel bearings and prevent costly roadside failures.