Properly tightening wheel bearings is crucial for safe driving and preventing premature wear on your vehicle’s components. Wheel bearings that are too loose can cause excessive play in the wheel hub, resulting in clunking noises when cornering, uneven tire wear, and vibrations in the steering wheel. On the other hand, overtightening wheel bearings can lead to premature failure, overheating, and seizing of the bearings. So how tight should wheel bearings be torqued to avoid these problems?

Page Contents

What are wheel bearings?

Wheel bearings are rolling-element bearings that allow the wheels to spin smoothly while supporting the weight of the vehicle. Most modern vehicles use tapered roller bearings, which consist of an inner and outer race (metal rings) with tapered rollers between them. The bearings are contained within a bearing housing that bolts to the steering knuckle. A circular cap called the adjusting nut sits on the end of the axle hub and is used to preload the bearing by tightening it to specified torque specifications.

Purpose of proper torque when tightening wheel bearings

Applying proper torque when installing wheel bearings serves several important purposes:

- Creates correct preload on the bearings to eliminate play while allowing low-friction rotation

- Evenly distributes load across all the roller elements in the bearing

- Prevents overtightening that can cause excess friction, heat buildup, and premature failure

- Secures the bearings in place to prevent loosening over time

- Minimizes stresses on bearing components and mounting hardware

- Helps optimize bearing life, performance, and reliability

The specified torque values are carefully calculated based on the bearing design, size, materials used, and application. Proper torque allows the bearings to handle their load carrying function optimally.

Signs of improper torque

Here are some symptoms that may indicate improper torque on the wheel bearings:

- Wheel wobble when spinning

- Clunking or clicking noises when cornering

- Growling or grinding from the wheel area

- Vibrations felt in the steering wheel

- Uneven tire wear (feathering or cupping)

- Wheel bearing feels too loose when rocked by hand

- Excessive heat around the bearing area

- Grease leakage from the bearing seals

- Difficulty turning the wheels by hand

These symptoms typically mean the bearings are under-torqued. Overtightening can also cause some of these issues and is often indicated if the wheel hub is very difficult to turn.

Finding manufacturer torque specifications

The recommended torque for tightening wheel bearings is provided by the vehicle or bearing manufacturer. Here are some ways to find the correct specifications:

- Vehicle owner’s manual

- Shop service manual for exact model and year

- Printed on the bearing packaging or box

- Listed in manufacturer product catalogs

- Available from manufacturer websites

- Marked on the bearing housing

- Listed on shop repair databases like Alldata or Mitchell

Torque values can range from about 50 ft-lbs for small passenger cars to over 200 ft-lbs for 3/4 and 1 ton trucks. Be sure to get the exact specifications – never guess or use a general guideline.

Using a torque wrench properly

A good quality torque wrench is essential to tighten wheel bearings to the correct torque. Here are some tips on using a torque wrench properly:

- Select a torque wrench suitable for your application based on the torque range and drive size (1/2″, 3/8″ etc.)

- Keep the wrench calibrated – check calibration regularly

- Make sure you understand the wrench markings and how to set the desired torque

- Rotate the handle or dial to the specified torque setting

- Apply force slowly and evenly until the wrench signals (clicks, lights up) that target torque is reached

- Do not exceed the torque setting or overtighten once the signal occurs

- Apply torque evenly in a crisscross pattern if tightening multiple bolts

- Avoid dropping or abusing the torque wrench

Using a quality torque wrench and technique helps eliminate guesswork and human error for consistent, accurate tightening of wheel bearings.

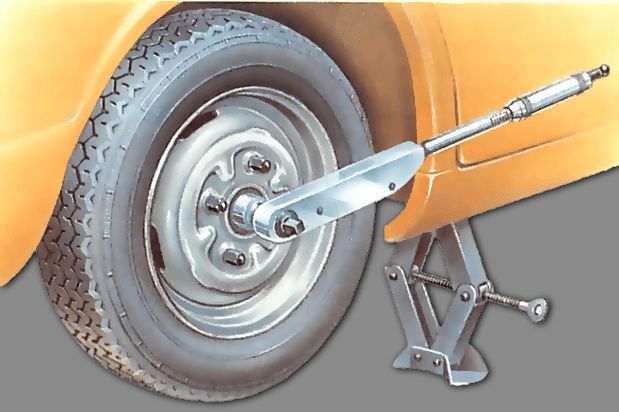

Step-by-step wheel bearing torque procedure

Here is a general step-by-step process for properly torquing wheel bearings:

- Consult vehicle service manual and locate proper torque specification for the specific bearing application.

- Inspect bearing, mounting hardware, and mating components. Make sure all are clean and in good condition.

- Pack the bearing with fresh wheel bearing grease if a sealed/maintenance-free unit is not being used.

- Install inner bearing race onto spindle and then install hub and outer bearing.

- Install washer and adjusting nut onto spindle and tighten to specification using a torque wrench.

- Check that the hub rotates freely without play.

- Install locking tab or bolt to secure adjusting nut.

- Recheck torque after test driving and double check proper end play.

Refer to the service manual for the full detailed procedure, specific to the vehicle’s bearing configuration. The above covers the critical torque aspects.

Troubleshooting wheel bearing torque problems

Here are some troubleshooting tips if you encounter problems related to improper wheel bearing torque:

- Double check torque specifications and that proper torque wrench and technique were used

- Inspect mounting hardware – damaged or stripped threads can affect proper torque

- Remove bearing and check for defects like pitting, flat spots, cracks etc.

- Make sure the spindle mounting surfaces are smooth and undamaged

- Use a dial indicator to check for excess endplay or too much preload

- Try a different brand new bearing – inferior quality bearings may be problematic

- Have mounting holes checked for roundness and proper dimensions

If bearing damage is found, the hub, seals, and races should be inspected too. Seek help from an experienced mechanic if the problem persists after checking all components.

Conclusion

Wheel bearings must be torqued to OEM specifications using proper tools and technique. This ensures the bearings are preloaded correctly to eliminate play while minimizing friction. Torque values are carefully calculated based on bearing type, size, vehicle load, and other factors. Under-torqueing can lead to noise and looseness while over-tightening causes excessive heat and rapid failure. Always torque wheel bearings based on factory procedures. Investing in a quality torque wrench and routinely checking calibration helps eliminate improper torque issues down the road.