Hot tubs are a great way to relax and unwind, either in your backyard or indoors. However, installing a hot tub directly on the ground can cause several problems. The weight of the full hot tub can cause the ground to become uneven or sink over time. Sitting directly on the ground can also allow moisture to seep in under the hot tub, potentially causing mold or mildew. To prevent these issues, it’s highly recommended to build a sturdy platform for your hot tub to sit on.

Building a platform helps level and support the weight of the hot tub. It raises the hot tub off the ground, preventing moisture issues. Platforms also provide easy access to the equipment and plumbing underneath the hot tub for maintenance. While you can hire a professional, building a hot tub platform yourself is an affordable DIY project. If done properly, it will provide a stable, long-lasting base for your hot tub.

This article will provide detailed steps on how to build a hot tub platform. We’ll cover how to plan the design, choose materials, lay the foundation, install the decking, and add final touches. Let’s get started!

Page Contents

Planning the Platform Design

The first step is to plan out the design for your hot tub platform. Here are some key factors to consider:

– Hot tub size – Measure your hot tub’s dimensions to determine the required platform size. Add 12 inches of overhang on all sides. This allows room to access plumbing and provides stability.

– Weight – Check the hot tub manual for the total filled weight. The platform must support this much weight. Larger hot tubs may require extra reinforcement.

– Location – Pick a flat, level area in your yard with good drainage. Consider ease of access to hook up utilities.

– Height – Typical height is 4-6 inches above ground. You want enough height for drainage without too much difficulty getting in and out.

– Shape – Make the platform the same shape as your hot tub. Rectangular and square platforms are most common.

– Materials – Pressure treated lumber is long-lasting outdoors. Composite decking is attractive but more expensive.

Once you know the size, shape, and height, you can start planning the structural support system.

Choosing Materials for the Platform

Here are the main materials needed to build a hot tub platform:

– Foundation blocks – Concrete blocks, concrete pavers, or treated timber to support base frame.

– Base frame – Pressure treated 4×4 or 4×6 beams to build the substructure.

– Joists – Pressure treated 2×8, 2×10, or 2×12 lumber spaced 16 inches on center.

– Decking – 5/4 or 2x pressure treated deck boards, cedar, redwood, or composite decking.

– Fasteners – Hot dipped galvanized screws or nails. Avoid plain steel fasteners.

– Vapor barrier – 6 mil polyethylene sheet placed under hot tub.

– Insulation – 2 inch rigid foam boards for leveling and insulating (optional).

The foundation blocks lift the wood framing off the ground. The base frame and joists provide structural strength. Decking creates the flat surface. Vapor barrier and insulation help control moisture and temperature.

Hot tub platforms are exposed to a lot of moisture. Use pressure treated lumber rated for ground contact. Pre-treated decking boards are fastened on top of the joists to create the platform surface.

Lumber Size and Quantity Estimates

The amount of lumber needed depends on your platform size. A typical 6 person hot tub platform would require:

– Foundation blocks: 16

– 4×6 beams: 8 at 10 ft length

– 2×8 joists: 15 at 12 ft length

– 5/4 decking: 24 at 16 ft length

Use these estimates to calculate your own lumber requirements once you know the platform dimensions.

Building the Foundation

The foundation established a solid base to frame the platform on. Here are the steps for this process:

1. Level and clear the build area of debris and grass.

2. Dig holes for the foundation blocks, spacing them about 6 ft apart.

3. Fill the holes with gravel and compact down 2-3 inches.

4. Position foundation blocks into holes, verifying blocks are level from side to side and front to back.

5. Use a gravel base if needed to level the blocks. Check with a 4 ft level.

6. Backfill dirt around blocks and pack firmly to hold in place.

The foundation blocks should now be stable, level, and ready to support the wood framing.

Framing the Platform

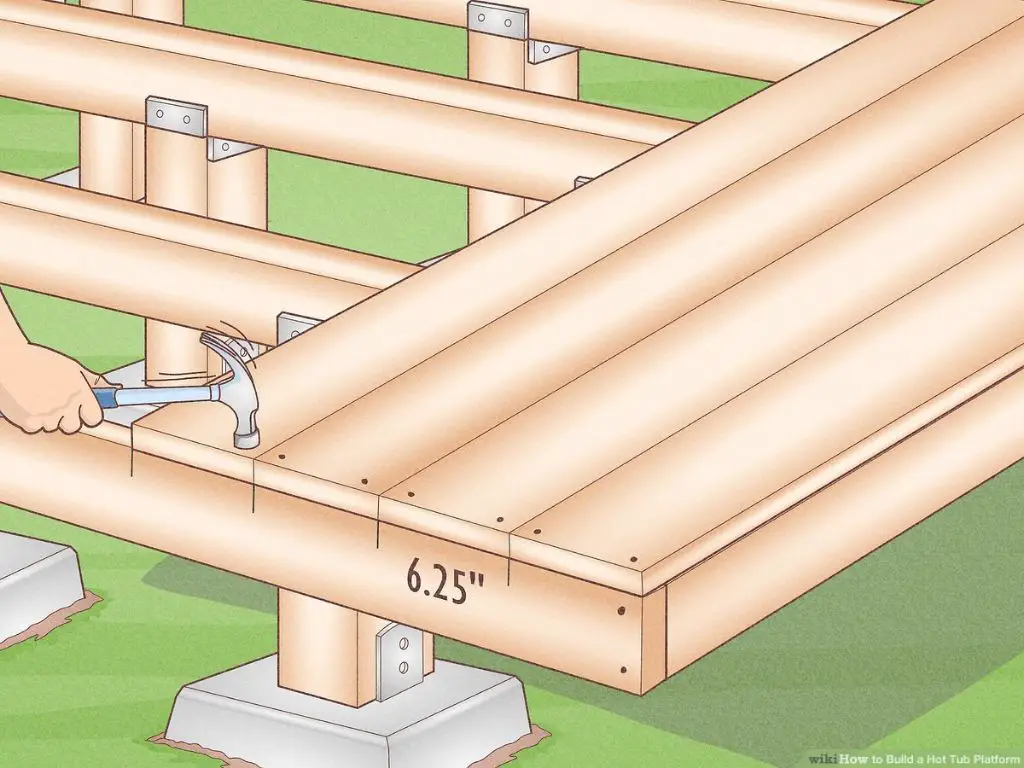

Once the foundation is laid, the next step is assembling the frame and joists. Follow these steps:

1. Cut (2) 4×6 beams to span the width of the platform.

2. Layout the beams parallel, 8 ft apart center-to-center.

3. Cut (2) more 4×6 beams to span the length, perpendicular to the first beams.

4. Fasten beams together with galvanized framing brackets and bolts.

5. Cut 2×8 joists to correct length, usually 12 ft long.

6. Layout joists 16 in on center between beams. Use joist hangers to attach.

7. Fasten rim joists around the outer edge.

8. Install blocking between joists around the perimeter.

The wood framing is now complete. Before installing decking, the next step is to cover the joists with a vapor barrier for moisture protection.

Table 1. Standard Joist Spacing

| Joist Size | On Center Spacing |

|---|---|

| 2×8 | 16 inches |

| 2×10 | 24 inches |

| 2×12 | 24 inches |

Adding Vapor Barrier

Condensation can drip from the hot tub and get trapped underneath the platform. A vapor barrier blocks moisture from seeping into the deck framing. Follow these steps:

1. Roll out 6 mil polyethylene sheeting over the joists.

2. Overlap seams at least 6 inches and tape together.

3. Cut sheeting around posts and obstructions.

4. Extend sheeting over outer rim joists.

5. Fasten sheeting to framing with deck screws every 12 inches.

The vapor barrier should now cover the entire frame surface before installing decking.

Installing Decking

With the frame and vapor barrier complete, you’re ready to fasten deck boards across the joists. Here’s how to complete the decking:

1. Start with perimeter deck boards. Rip boards to correct width.

2. Fasten boards to rim joists with 2 screws at each joist.

3. Fill in center decking boards, spacing 1/8 inch between boards.

4. Stagger end seams at least 4 joists apart.

5. Use screws spaced every 8 inches along joists. Countersink.

6. Miter cut final boards and use trim pieces around outside edges.

7. Make sure deck boards are smooth and no nails protrude.

The platform is really coming together now! Once decking is installed, only a few finishing touches remain.

Table 2. Recommended Decking Materials

| Material | Cost | Durability |

|---|---|---|

| Pressure Treated | $$ | High |

| Cedar | $$$ | Good |

| Composite | $$$$ | High |

Finishing Touches

The last steps complete the platform and get it ready for the hot tub:

– Seal all decking screws with exterior sealant to prevent corrosion.

– Attach trim boards around exposed joist ends and other openings for a finished look.

– Stain or seal the platform if desired. Allow any finish to fully dry.

– Cover the platform when not in use to protect from weathering.

– Build steps for easy access into the hot tub.

– Level the ground around the hot tub pad to prevent water runoff issues.

Once complete, carefully move the hot tub into position on the platform. It’s also recommended to place a foam pad on top of the platform where the hot tub will sit to better protect the finish from chemical damage.

Connect the utilities, fill it with water, and your hot tub platform is ready for relaxation! Proper maintenance will keep your platform level and intact for many years.

Conclusion

Building a hot tub platform is an important step when installing a hot tub, both for functionality and longevity. This article provided a detailed overview of the entire process from start to finish:

– Design considerations – size, shape, height

– Material selection – foundation, framing, decking

– Step-by-step instructions for each phase – foundation, framing, vapor barrier, decking, finishing

– Recommendations for best practices

The process requires proper planning, an understanding of building principles, and correct tool usage. But the end result is well worth it – a stable, level hot tub base that will last for decades. Constructing your own hot tub platform is an extremely rewarding project that will save thousands over hiring a professional.