Fluorescent light fixtures have been a staple in offices, schools, hospitals, and other commercial buildings for decades. They provide bright, energy-efficient illumination. However, fluorescent lights rely on a ballast to regulate power flow and start the lamps. Over time, old electromagnetic ballasts can fail or cause flickering, buzzing sounds, and other issues. Replacing just the failed ballast provides an easy fix, but installing a new electronic ballast offers advantages. Below we’ll explore common ballast problems, the pros and cons of ballast replacement, and help determine if an upgrade is worthwhile.

Page Contents

What is a ballast?

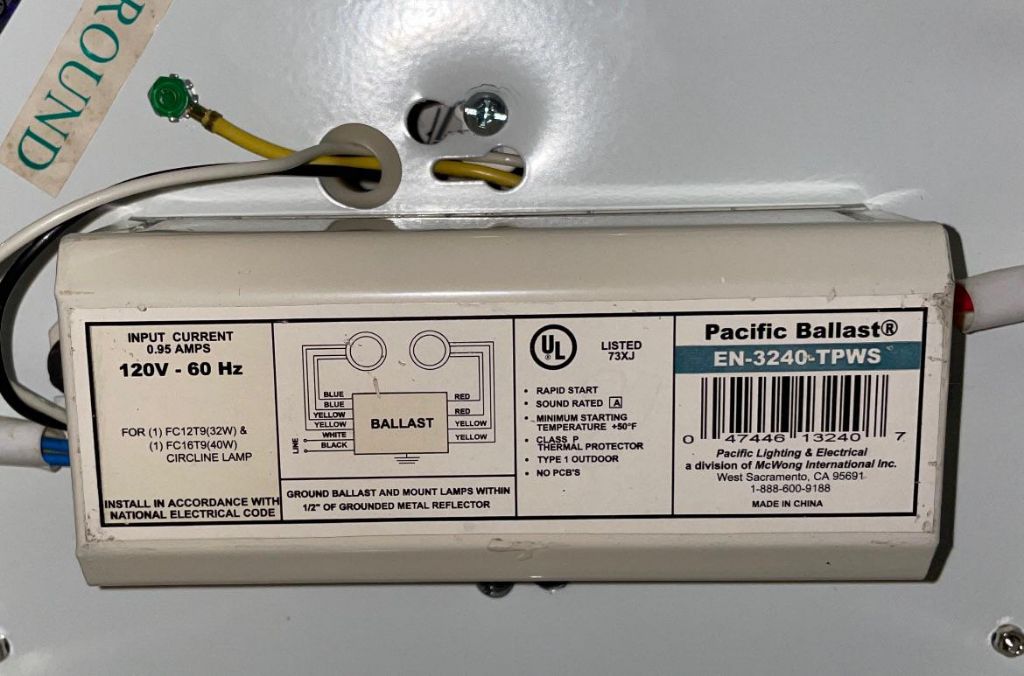

A fluorescent light ballast is a critical component that controls the start-up process and operation of fluorescent lamps. There are two main types of ballasts:

Electromagnetic ballasts

Early fluorescent lighting systems used electromagnetic ballasts. An electromagnetic ballast contains a coil of wire that forms a magnetic field when electrical current flows through it. The changing magnetic field induced in the coil acts as a voltage transformer and provides the high starting voltage required to initially ionize the gas and mercury vapor in fluorescent tubes. Once the lamps have started, the magnetic field drops to a lower level to limit the current flowing through and prevent overheating.

Electromagnetic ballasts are large, heavy devices that can produce an audible humming or buzzing noise during operation. They lack efficiency compared to modern electronic ballasts.

Electronic ballasts

Electronic ballasts use solid-state electronic circuitry instead of bulky coils and magnets. The circuitry efficiently provides the starting voltage spike and stable operating current to fluorescent lamps. Electronic ballasts operate silently and have many advantages over electromagnetic types:

– More energy efficient – Use 10-25% less power

– Lighter weight

– No humming or buzzing sounds

– No flickering issues

– Longer bulb life

– Operate well in cold temperatures

– Dimming capability

Most fluorescent lighting systems manufactured after 1990 contain electronic ballasts. Since they have fewer components, electronic ballasts are also more reliable and last longer on average.

Common ballast problems

Faulty ballasts cause many problems with fluorescent lights. Some common symptoms include:

Frequent bulb failure

If lamps burn out repeatedly after short periods, the ballast is likely overheating and damaging the bulb cathodes. An electromagnetic ballast nearing the end of its service life may overheat. Installing a new electronic ballast will prevent premature bulb failure.

Flickering/strobing lights

A flickering fluorescent light with a strobe effect indicates a bad ballast. Electromagnetic ballasts can cause flickering as they age. Loose internal connections can also cause intermittent problems. Replacing the failing ballast cures the issue.

Buzzing or humming

Noisy ballasts are annoying. The buzzing or humming is caused by electromagnetic interference in the coil inside electromagnetic ballasts. Magnetic ballasts should be replaced with quieter electronic models.

Slow starting/low light output

If fluorescent bulbs take a long time to start or seem dim, the ballast may not be providing the proper starting voltage and power. A bad ballast prevents the fluorescent tubes from lighting fully. Replacing the faulty ballast restores proper starting and operation.

One bulb out/end blackened

Blackened ends or one bulb not lighting indicates the ballast failed in an open-circuit mode. This prevents voltage from reaching the affected socket. Replace the ballast to restore normal operation.

Won’t start

If a fluorescent light does not start at all, the ballast is likely dead. Ballasts can suddenly stop working if an internal component fails. Simply replacing the ballast will get the light working again.

Reasons to replace a ballast

Here are the main benefits of replacing defective or older electromagnetic ballasts:

Fixes lighting issues

Replacing a bad ballast cures many problems, including flickering lights, slow starting tubes, and premature bulb failure.

Improves efficiency

Upgrading to electronic ballasts can cut lighting power consumption by up to 25%. This saves on electricity costs.

Eliminates buzzing/humming

New electronic ballasts operate silently. Workers will appreciate the removal of annoying electromagnetic ballast noise.

Enhances brightness

A properly operating electronic ballast delivers optimal voltage to maximize fluorescent light output. Rooms will be brighter.

Increases reliability

Electronic ballasts last longer, with a typical lifespan over 50,000 hours. Facility maintenance is reduced.

Simplifies repairs

Faulty ballasts are quick and easy to replace. Trying to repair old electromagnetic ballasts is not worthwhile.

Prepares for upgrades

New electronic ballasts are compatible with T8 and energy-saving T5 fluorescent lamps. Upgrading now eases the transition to more efficient lighting.

Reasons not to replace a ballast

Here are a few reasons you may want to hold off on ballast replacement:

Recent installation

If fluorescent fixtures with new electronic ballasts were recently installed, leave them alone. Typical ballast life is over 50,000 hours, so replacements should not be needed.

Planned lighting upgrades

Ballast replacement may not be worthwhile if planning a complete lighting system upgrade to LED technology in the next 1-2 years.

Low-use fixtures

Fix or replace ballasts in frequently used lights first. Ballasts in fixtures rarely turned on may have more years of service life left.

Insufficient budget

Postpone upgrades if the budget is not available. Focus funds on critical lighting needs first.

Unsure of ballast issues

Diagnose ballast problems first before replacing. Intermittent flickering or slow starting bulbs can also stem from faulty lamps or loose connections.

DIY or hire an electrician?

Replacing ballasts in commercial lighting fixtures often requires a qualified electrician. Here are important considerations:

Know safety procedures

Ballast replacement involves high voltages. Ensuring circuits are disconnected is critical for safety. Leave the work to experienced pros.

Have technical expertise

Electrical knowledge is required to properly wire the variety of ballast types you may encounter. Mistakes can cause dangerous shorts or shocks.

Meet code requirements

Commercial ballast retrofits must adhere to electrical and building codes. Licensed electricians understand the requirements.

Use lifts for high ceilings

Equipment like scissor lifts or scaffolding is needed to safely access light fixtures with high ceiling mounting heights. Rentals are expensive.

Manage lamp disposal

Fluorescent lights contain mercury and must be disposed of properly as hazardous waste. Companies are better equipped to handle.

Have group relamping capability

To maximize savings, companies can replace all lamps throughout a building when servicing ballasts. This group relamping is challenging solo.

For most commercial properties, the scale of required ballast upgrades makes hiring an electrical contractor the smartest choice. Paybacks from enhanced efficiency and reliability outweigh the project costs.

Ballast replacement project steps

If you are considering a ballast replacement project, follow these key steps to ensure success:

Audit lighting and identify bad ballasts

Survey all fluorescent fixtures to find units with failed or noisy ballasts. Note locations and quantities for planning.

Evaluate replacement options

Decide between altering existing fixtures to accept new ballasts or completely replacing old lighting equipment. factor in costs, installation time, payback period, and expected results.

Create a project plan

Define the scope, budget, timeline, resources required, electrical considerations, disposal needs, and all aspects of the project.

Hire contractors

Solicit bids from qualified electrical contractors experienced in fluorescent lighting retrofit projects. Verify all licensing and certifications.

Schedule installation

Time the project to avoid disrupting critical facility operations. Coordinate to avoid problems.

Inspect final results

When finished, thoroughly inspect all changed fixtures for proper operation. Confirm expected energy savings via metering.

Cost of ballast replacement

Here are typical ballast replacement costs:

| Item | Cost per unit |

| New electronic ballast | $25-$60 |

| Ballast installation labor | $100-$200 per fixture |

| Group relamping with new bulbs | $10-$25 per lamp |

| Lamp disposal fees | $1-$4 per bulb |

| Lift/equipment rentals | $100-$500 per day |

Total costs for an entire retrofit project vary based on the number of fixtures serviced, ceiling height, and local labor rates. Budget appropriately based on the specific conditions.

Payback period

The costs of ballast replacement can pay for themselves through lower energy bills. With new electronic ballasts cutting lighting power use by 20% or more, payback takes 1-3 years in many cases. Facilities with 24/7 operation achieve payback quickest.

We can calculate the payback period using this formula:

Payback Period = Ballast Replacement Cost / Annual Energy Savings

For example, replacing ballasts in 100 fixtures cost $7,500 total. The project cut lighting energy use by 25%, saving $1,500 annually. The payback period is:

$7,500 / $1,500 per year = 5 years

After the payback period, the lighting upgrades continue providing savings each year. For most companies, a lighting retrofit paying for itself in 5 years or less is an excellent return on investment.

Should you replace fluorescent light ballasts?

Here is a summary of when fluorescent light ballast replacement makes sense:

If ballasts are failing

Replace any ballasts causing flickering, buzzing, or illumination issues. This will restore proper fixture operation.

To stop frequent lamp failures

Upgrade electromagnetic ballasts overheating and burning out bulbs prematurely.

For energy and cost savings

Take advantage of energy savings from electronic ballasts. The payback period is relatively short.

Removing annoying ballast noise

The humming and buzzing of magnetic ballasts detracts from the work environment. Replace for quieter fixtures.

As part of lighting upgrades

When upgrading to T8 or T5 lamps, install compatible electronic ballasts at the same time.

Before switching to LEDs

If LED lighting retrofits are planned within 5 years or so, replace ballasts now to improve fluorescent fixture performance in the interim.

Conclusion

Replacing fluorescent light ballasts provides many benefits. New electronic ballasts fix lighting problems, enhance efficiency and brightness, operate quietly, and have excellent lifespans. With attractive payback periods of just a few years, ballast upgrades are worthwhile for most organizations. Proper project planning and hiring qualified electrical contractors ensures the retrofit goes smoothly. For better performing and more sustainable fluorescent lighting, replacing worn or electromagnetic ballasts with electronic models is typically a smart long-term investment.