Paper faced corner bead is a common drywall accessory used to create clean corners and edges on walls and ceilings. It consists of a paper tape laminated to a metal or plastic L-shaped strip. But is it a good choice for your drywall project? There are pros and cons to consider when deciding between paper faced corner bead and alternatives like metal corner beads or flexible corner beads.

Page Contents

- 1 The Pros of Paper Faced Corner Bead

- 2 The Cons of Paper Faced Corner Bead

- 3 Better Moisture Resistance with Plastic Beads

- 4 Fibglass Mesh Corner Bead Alternatives

- 5 When to Use Metal Corner Beads

- 6 Flexible Vinyl Corner Beads

- 7 Conclusion

- 8 Frequently Asked Questions

- 9 Installing Paper Faced Corner Beads

- 10 Typical Prices

- 11 Common Sizes

- 12 Types of Paper Beads

- 13 Paper vs Mesh Tape for Finishing

- 14 Painting Tips

The Pros of Paper Faced Corner Bead

Here are some of the benefits of using paper faced corner bead:

- Easy installation – Paper faced corner beads are relatively easy for DIYers to install. The paper tape strips make it simple to embed the beads in joint compound and blend them seamlessly into the wall.

- Smooth finish – The paper covering gives an immediate smooth surface for applying joint compound and finishing the corner. This can reduce the amount of coats and sanding required.

- Damage resistance – The metal or plastic reinforcing strip behind the paper provides impact protection. Corners finished with paper faced beads resist cracking and denting better than corners without reinforcement.

- Inexpensive – Paper faced metal corner beads are generally one of the most economical corner bead options. Plastic paper faced corner beads are also very affordable.

- Widely available – Paper faced corner beads are easy to find at home improvement stores and construction supply retailers. They come in various styles and sizes to suit different applications.

The Cons of Paper Faced Corner Bead

There are also some potential downsides with paper faced corner bead to consider:

- Durability issues – The paper surface is vulnerable to damage from moisture and physical impacts. The laminated paper can bubble or delaminate over time.

- Limited flexibility – Paper faced beads are rigid and difficult to bend, which can make installing them on curved or uneven walls challenging.

- Difficult repairs – Damaged paper beads are not easily repairable. Entire sections often need to be removed and replaced.

- Messy cuts – Cutting or notching paper faced beads to size produces paper debris that must be cleaned up before finishing.

- Prone to cracks – The paper and joint compound over it can develop hairline cracks at the apex of the corner over time.

Better Moisture Resistance with Plastic Beads

One of the biggest issues with paper faced metal corner beads is that moisture can cause the paper to bubble or delaminate. Plastic paper faced corner beads offer better water resistance. The plastic-paper coating is more durable and flexible. Plastic corner beads are ideal for bathrooms, basements, kitchens, and other damp areas prone to splashing.

Fibglass Mesh Corner Bead Alternatives

Fiberglass mesh corner beads are another choice that avoids the vulnerabilities of paper materials. Mesh corner beads have an open weave fiberglass fabric coating over a metal or plastic form. The mesh material embeds easily into joint compound for smooth finishing. Since there is no paper, moisture damage is not an issue. Mesh corner beads are also very flexible and easy to install around curved walls.

When to Use Metal Corner Beads

For very high-impact areas, metal corner beads may be the best option. Some metal corner beads have no covering at all and provide the most durable reinforcement. These work well for garage walls, basements, and commercial buildings that will experience a lot of abuse. The bare metal beads require some extra skill to feather out the joint compound and achieve smooth finished corners.

Flexible Vinyl Corner Beads

Flexible vinyl corner beads offer an alternative with more bend and impact resistance than paper beads. These have a thin vinyl coating over metal or plastic. The flexible material makes installing around curved walls easy. The vinyl provides good moisture resistance too. Flexible corner beads cost a bit more than paper faced beads but are very durable.

Conclusion

Paper faced corner beads are a good economical choice for many drywall projects. They are easy to install and create nice finished corners. However, the vulnerability of the paper to moisture and damage makes them less than ideal for some situations. Plastic, mesh, metal, and flexible vinyl corner beads can be better suited for bathrooms, high-traffic areas, curved walls, and extreme impacts. Consider the location and your own DIY skill level when deciding between the different corner bead options.

Frequently Asked Questions

What are the advantages of paper faced corner beads?

Some key advantages of paper faced corner beads include:

- Smooth finished surface

- Impact resistance

- Low cost

- Easy installation

- Wide availability

What are the disadvantages of paper faced corner beads?

Some potential disadvantages of paper faced corner beads are:

- Prone to moisture damage

- Can crack over time

- Not very flexible

- Difficult to make repairs

- Messy to cut and install

When should other corner bead options be used?

Alternatives like plastic, mesh, metal, or flexible vinyl corner beads may be better choices for:

- Bathrooms or damp areas

- Highly curved walls

- Areas that experience frequent impacts

- Commercial construction

- DIYers with less experience

Are plastic paper faced beads more water resistant?

Yes, plastic paper faced corner beads generally provide better resistance to moisture and water damage compared to paper faced metal beads. The plastic helps prevent bubbling or delamination.

Do mesh corner beads crack easily?

No, fiberglass mesh corner beads are less prone to cracking than paper faced corner beads. The mesh material and joint compound flex over time to resist cracks better.

Installing Paper Faced Corner Beads

Installing paper faced corner beads takes some practice but can be managed by novice DIYers with proper techniques. Here are some tips for smooth installation:

- Cut beads slightly longer than the wall – Leave 1/4″ to 1/2″ extra and trim to fit cleanly.

- Embed beads in joint compound – Apply compound to the corner, spread flat, and press in the bead.

- Smooth with finesse – Carefully glide a 6″ drywall knife along the edges to avoid tearing the paper.

- Apply three coats – Build up the corner with progressively wider coats for a seamless finish.

- Avoid over-sanding – Lightly sand each coat but don’t sand down to the paper.

With some practice and the right techniques, paper faced corner beads can be installed perfectly on both inside and outside drywall corners. Take it slowly and let joint compound fully dry between coats. The finishing results will be smooth, strong corners that resist cracking and impacts.

Typical Prices

Paper faced corner beads are very economical. Here are some typical price ranges:

- Paper faced metal corner beads – $1 – $3 per 8-10′ length

- Plastic paper faced corner beads – $2 – $5 per 8-10′ length

- Vinyl and metal corner beads – $3 – $7 per 8-10′ length

- Fiberglass mesh corner beads – $5 – $10 per 8-10′ length

Prices vary based on the corner bead width, brand, and retailer. But paper faced metal beads are generally the least expensive option for most projects.

Common Sizes

Paper faced corner beads come in a range of widths to suit different wall thicknesses:

| Corner Bead Width | Wall Thickness Fit |

|---|---|

| 1/2″ | 1/2″ drywall |

| 5/8″ | 5/8″ drywall |

| 3/4″ | 1/2″ drywall with plaster |

| 7/8″ | 5/8″ drywall with plaster |

| 1-1/4″ | Thick 9/16″ or 5/8″ fire-rated drywall |

| 1-1/2″ | Multiple layers of drywall |

Measure wall thickness and existing corner gaps when selecting the right paper bead size.

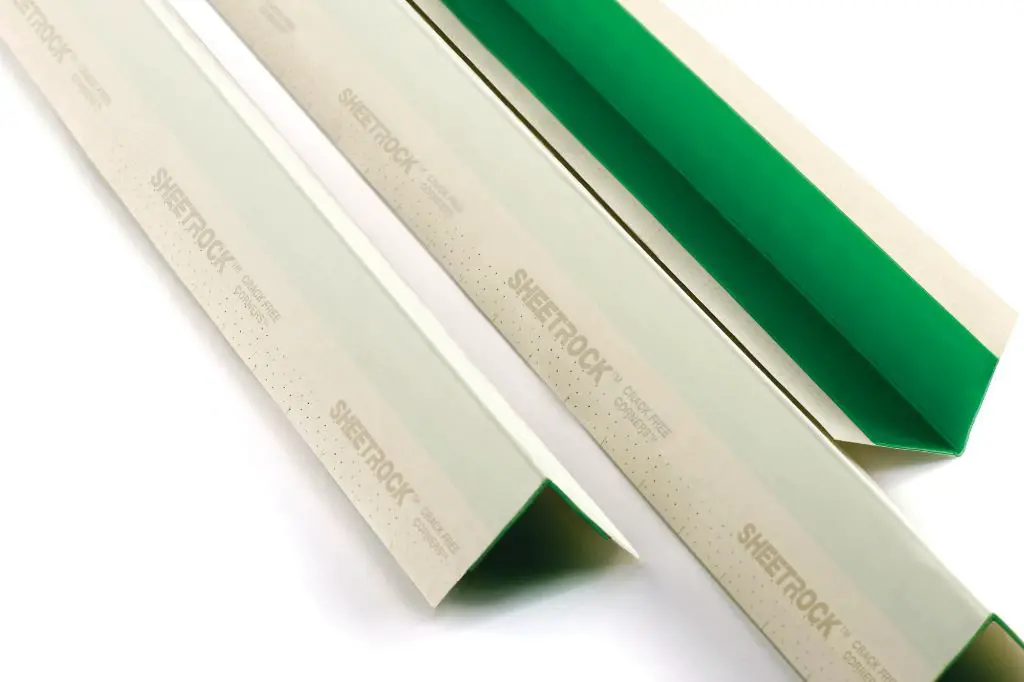

Types of Paper Beads

There are a few specific types and styles of paper faced corner beads:

- Bullnose – Rounded tapered edges

- L-beads – 90 degree inside/outside corners

- U-beads – Finishing bead for drywall edges

- Archway – Pre-formed curved arches

- Offset – For right angle offsets in walls

Bullnose and standard L-bead corner beads are the most widely used. But other styles are also available for specialty applications.

Paper vs Mesh Tape for Finishing

For the final layer of joint compound over corner beads, paper drywall tape or mesh tape can be used. Here’s how they compare:

- Paper tape – Blends into compound well but prone to bubbling

- Mesh tape – More resistant to cracks but shows through thinner coats

Mesh tape works best for the final thin skim coat. Paper tape is good for the first thicker coats but may bubble. Using mesh over paper combines the benefits of both.

Painting Tips

To achieve smooth painted corners, follow these tips after installing paper faced corner beads:

- Feather out joints with wide drywall knife

- Fill any cracks or pits with spackle

- Sand lightly when dry

- Prime before painting

- Apply two coats of quality paint

Take time to properly prepare the corners and avoid glossy paints that will highlight imperfections. The end results will be crisp, clean painted corners.