Page Contents

Quick Answer

Using a belt dressing on a serpentine belt is generally not recommended. Serpentine belts are made from advanced rubber compounds that are designed to grip pulleys without the need for additional products. Belt dressings can actually cause the belt to slip more by making the pulleys slick. They can also damage the rubber and cause the belt to wear out faster. The best way to care for a serpentine belt is through proper tensioning and alignment. If squeaking persists, the root cause should be addressed rather than just applying a dressing.

What is a Serpentine Belt?

A serpentine belt is a multi-ribbed belt that powers multiple accessories on the front of an engine. It replaced the older V-belts and single belts that were used for each accessory. Serpentine belts wrap around pulleys for components like:

- Alternator

- Power steering pump

- Air conditioning compressor

- Water pump

Modern serpentine belts are made from advanced EPDM (ethylene propylene diene monomer) rubber. This provides excellent flexibility, strength, and grip. Many also have aramid or carbon fiber cords to add durability and prevent stretching.

Benefits of a Serpentine Belt

Some key benefits of serpentine belt systems include:

- Powers multiple accessories with one belt

- Simplifies maintenance – only one belt to replace

- Smoother and quieter operation

- More efficient use of engine power

By turning several accessories with a single belt, there is less load on the engine. This increases fuel efficiency. The serpentine belt system was an important innovation for modern engines.

Should You Use Belt Dressing?

Belt dressings like Belt Grip and Belt Sauce used to be recommended for older V-belts that slipped. But serpentine belts are made from modern compounds that grip better. Applying belt dressing to a serpentine belt can actually do more harm than good. Here’s why it’s generally advised against:

- Makes pulleys slick – dressings act as lubricants, reducing grip

- Attracts dirt – slick pulleys attract more dirt and debris

- Damages belt – petroleum distillates soften rubber

- Causes belt wear – dressing leads to slippage and wear

Rather than just masking symptoms of a slipping belt, it’s better to address the root cause. Problems like misalignment, low tension, or a bad pulley or idler should be fixed.

Signs You Shouldn’t Use Belt Dressing

Here are some signs that indicate dressing won’t help and the underlying problem needs to be addressed:

- Belt has visible damage like cracks

- Belt is very worn or glazed

- A pulley bearing or bushing is failing

- There’s debris buildup on pulleys

- Belt has been slipping for a long time already

In these cases, a new belt and/or pulley repairs are needed. Covering them with dressing won’t provide a lasting fix.

How to Maintain a Serpentine Belt

Here is the proper way to care for a serpentine belt:

Check Condition

Inspect belts periodically for signs of cracking, fraying, or damage from foreign objects. If deterioration is found, replace the belt.

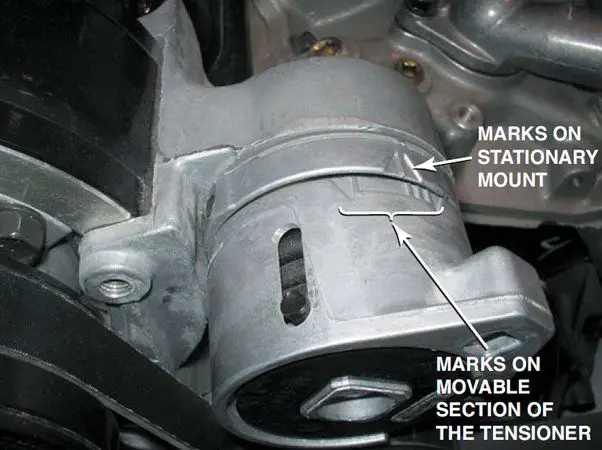

Ensure Proper Tension

Loose belts will slip and fail prematurely. Use a belt tension gauge to check tension against manufacturer specs. Increase tension using an auto-tensioner or manual adjuster.

Verify Alignment

Misalignment causes uneven wear and noise. Check that pulleys are parallel using a straightedge. Correct minor issues by adjusting pulley mounts.

Check Pulleys and Bearings

Damaged, bent or seized pulleys put additional strain on belts. Test pulleys for smooth, free rotation. Replace any worn components.

Clean Pulleys

Use a degreaser and stiff brush to remove built-up grime on pulleys. This prevents belt slippage.

Following proper maintenance intervals will maximize belt life and prevent slipping issues. Address alignment, tension and pulley issues immediately.

Alternative Solutions

If you’re experiencing belt noise or slippage, here are some better solutions than just using dressing:

New Belt

Installing a fresh belt is the easiest solution that immediately stops slippage. Ensure it’s tensioned correctly.

Realign Pulleys

Check pulley alignment with a straightedge and adjust mounts as needed to line them up.

Replace Pulleys

Worn, bent or seized pulleys put strain on belts leading to failure. Install new pulleys and bearings to prevent slipping.

Correct Idler Position

Idler pulleys maintain proper tension. Make sure they pivot freely and are in the right position.

Check Belt Type

Verify you have the correct belt for your accessory configuration and pulley sizes. An incorrect belt won’t grip right.

Taking the right steps to fix underlying problems will eliminate the need for questionable belt dressings. Your serpentine belt system will last longer and run quieter.

When Belt Dressings May be Acceptable

While not generally recommended, here are some cases where a belt dressing could have some temporary benefit:

- Emergency roadside fix to stop slipping long enough to get home or to a shop

- Older classic cars with worn V-belts that can’t be replaced readily

- Agricultural equipment uses in remote areas to prevent downtime during harvest

- Reducing noise from minor belt slippage that doesn’t impact function

But even in these situations, it’s wise to thoroughly inspect the belt system and have proper repairs done soon. Avoid using dressing for an indefinite period of time.

Conclusion

Serpentine belt dressing or grip spray is not the best answer for most slipping belt issues. These products can actually make problems worse long-term. It’s better to properly maintain belts and fix underlying issues like tension, alignment and damaged pulleys. This will maximize the belt life while minimizing noise.

The exceptions are temporary, emergency scenarios to get a short reprieve from annoying slippage. But a belt dressing should never be used as an ongoing maintenance practice for modern serpentine belt drive systems. Seeking out and repairing root causes is far more effective. This prevents accelerated belt wear and damage from inadequate grip on the pulleys. With proper belt care, dressings are unnecessary.