A pocket hole jig is a handy woodworking tool that allows you to drill angled holes to create strong joints by driving screws at an angle into the wood. However, not everyone has a pocket hole jig or wants to buy one. Luckily, there are some good alternatives you can use to achieve similar strong joining results without this specialized tool.

In this article, we’ll go over what exactly pocket holes are, why they are useful, and then provide a variety of options for alternatives you can use if you don’t have a pocket hole jig. We’ll cover both temporary solutions using items you likely have on hand as well as other jigs or techniques you can invest in for repeated use.

Page Contents

What Are Pocket Holes?

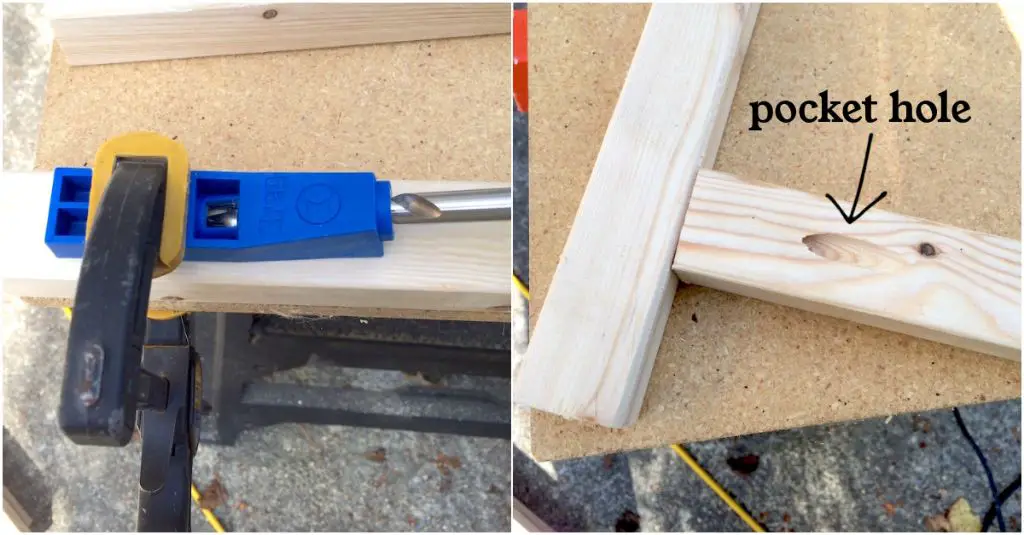

Pocket holes, also sometimes called pocket screw holes, are angled holes drilled into one piece of material (like a wood board) so that you can join it securely to another piece by driving a screw into the angled hole.

The screw gets driven into the second board at an angle, allowing for a strong mechanical connection. The angled hole also allows the screw head to nestle into the hole below the surface so it can be concealed for a cleaner look.

The key advantage of pocket screws over other joints like butt joints is that they allow you to create frames, boxes, cabinets, and other right angle joints that are both strong and attractive looking. The angled screw allows for good clamping force to join the two boards tightly together.

Why Use Pocket Holes?

Here are some of the main benefits pocket hole joinery provides:

– Strong mechanical joint – The angled screw provides excellent holding power to tightly join boards together. The resulting joint can often be stronger than the wood itself.

– Concealed joinery – With the screw head buried in a hole, the joint has a smooth, seamless look when assembled.

– Quick and easy assembly – Pocket holes allow you to drill angled holes ahead of time. Then assembly is as easy as adding glue and driving in screws.

– Versatile – Pocket holes can be used to create all kinds of right angle joints like frames, boxes, tables, cabinets, and any situation where two boards meet at a 90 degree angle.

– No specialty clamps needed – The angled screw provides the clamping force to pull joints tightly together as you screw them in.

So in summary, pocket holes create strong joints quickly, cleanly, and without need for additional clamps or complicated joinery techniques. But you need the right pocket hole jig and drill bit to drill the properly angled holes.

Pocket Hole Jig Alternatives

If you don’t have a pocket hole jig, don’t worry, you still have many options for creating similar strong mechanical joints. Here are some alternatives to consider:

Use a Block of Wood

You can create a simple pocket hole jig substitute by using an angled block of scrap wood. Just cut a block at the required angle and clamp it to your workpiece to drill into. The angle for most pocket holes is 15 degrees, but you can adjust the angle of your block as needed.

Sandwich the block between your workpiece and a drill guide or another clamped block to drill straight angled holes. This won’t allow the precision of a jig but can work in a pinch.

Use a Screw Insert Drill Bit

Special stepped drill bits are made to create angled holes for inserting threaded inserts. While designed for inserts, these can also be used just to drill pocket screw holes at the desired angle in your boards.

Simply clamp your work and use one of these stepped drill bits in your drill press or handheld drill to bore the angled holes. You get accurately angled holes without a jig.

Kreg Jig Knock-Offs

Many power tool brands offer their own pocket hole jig systems that are compatible with Kreg pocket screws and drill bits. These are basically Kreg jig knock-offs – they copy the Kreg design and function but at a lower price point.

Brands like Wolfcraft, Milescraft, Triton, and Powertec all offer Kreg-like pocket hole drilling guides often at about half the Kreg price. The quality may not be quite as good, but they will get the job done.

Woodworker Pocket Hole Jigs

There are also pocket hole jigs geared specifically for the serious woodworker rather than occasional home DIY use. Brands like Woodpeckers, Rockler, and Eagle America offer premium cast iron pocket jigs for those wanting the best quality and most precise holes.

For example, the Woodpeckers Unibody jig has a beefy one-piece cast body and precision ground drill bushing for added accuracy. For avid woodworkers, an upgrade like this may be worth the higher price over time.

Make Your Own Pocket Hole Jig

You can also find many plans online for making your own pocket hole jig completely from scratch. This is a good option if you have access to woodworking tools and want the challenge of creating your own.

Most DIY jig plans involve building a sliding table to adjust for different wood thicknesses. You can reuse a stepping drill bit holder or install a drill bushing at the required angle. Add stops for consistent hole depth and you’ve got a homemade jig!

Use an Adjustable Angle Drill Guide

Another handy tool that lets you drill angled pocket holes is an adjustable angle drill guide. MilesCraft, Wolfcraft, and other brands make drill guides that attach to your workpiece and allow you to dial in and lock the angle you want to drill.

Just set it to the proper pocket hole angle, lock it, and drill away. Like DIY jigs, most of these guides lack the refinements of a dedicated pocket hole jig but can work.

Toekick Drill Jig

Jigs made for drilling toe kick ventilation holes in cabinets and furniture are also handy for pocket holes. Brands like Milescraft offer drill guides with a fixed 15 degree angle, perfect for pocket holes. You just align and clamp the jig to drill straight into the workpiece.

Again, not as precise as a real pocket hole jig but a good workaround that won’t break the bank.

Use a Doweling Jig

Here’s an outside-the-box idea – use a doweling jig! Dowel jigs are made to line up holes to join boards with wood dowels. But you can also drill pocket holes with many models.

Search for a dowel jig with a capacity of at least 2” to allow enough room for pocket screws. Drill out the dowel holes but insert screws instead of dowels to take advantage of the angled alignment of the jig.

Alternative Joints and Joinery

Beyond just recreating the pocket hole, there are also some alternate forms of joinery and joints you can use instead that will still give strong results:

– Butt Joints – A simple flat butt joint glued and screwed from the face into the edges of the boards.

– Biscuits – Small football-shaped biscuits you glue into slots to help align panels and boards.

– Dowels – Glue and drill evenly spaced dowels to join boards. Similar to biscuits.

– Dado Joints – Dado grooves cut in one board to accept the mating piece for shelf-like joints.

– Box Joints – Interlocking “fingers” cut into the wood edges that fit together like a puzzle.

– Rabbet Joints – A rabbet notch cut into one board to receive the mating piece. Great for cabinet backs.

– Tongue and Groove – Boards with a protruding “tongue” that fit into a grooved board.

– Mortise and Tenon – A tenon cut on one board that fits into a mortise hole on the mating piece. Very strong.

Each has its own advantages and drawbacks depending on your specific project needs. Experiment to see which might replace pocket holes well for your application.

Temporary Pocket Hole Substitutes

The options above are good alternatives if you’ll be doing a lot of pocket hole joinery-type projects. But for a temporary quick fix, here are some options using supplies you likely already have on hand.

Use Drywall Screws

For lightweight DIY and repair projects, simply driving long drywall screws at an angle into the mating pieces can provide enough holding strength. The angled screw provides some clamping force and mechanical grip.

Use Finish Nails

Another temporary option is finishing nails. Drive sturdy finish nails at angles through the top board and partially into the bottom board. The angled nails act like mini versions of pocket screws to hold boards together.

Use a Construction Adhesive

For small projects or repairs that don’t bear heavy loads, construction adhesive alone may work. Apply adhesive to both mating surfaces, clamp pieces together tightly, and allow the adhesive to cure fully.

The glue bond is surprisingly strong on its own in ideal conditions. Just don’t expect it to be as strong as with screws or nails.

Conclusion

While pocket hole joinery is an extremely useful technique, you’re not necessarily limited if you don’t have the proper jig on hand. Using angled blocks or drill guides, buying knock-off jigs, making your own, or simply utilizing alternative joinery methods can all give comparable results.

And for lightweight or temporary repairs, common supplies like screws, nails, or glue can also substitute in a pinch. Just remember most alternatives won’t provide the same strength and precision as a dedicated pocket hole jig. But with some creativity, you can still find ways to drill angled pocket holes or make comparable joints without this specialty tool.

Frequently Asked Questions

What angle do I need to drill pocket holes?

Most pocket hole jigs are designed to drill holes at a 15 degree angle. However, you can adjust this angle as needed – some woodworkers use angles between 10-20 degrees depending on the application.

What screws work best for pocket holes?

Special hardened pocket hole screws are best since they have a pointed tip, coarse threads, and flat screwdriver head. However, you can also use other screws like exterior wood screws. Avoid finer thread screws like sheet metal or drywall screws.

Do I need special clamps with pocket holes?

A benefit of pocket holes is that the angled screw provides the clamping force, so no special clamps are required in most cases. You can typically assemble joints by driving screws alone. Apply glue as well for a stronger bond.

How deep should I drill pocket holes?

Drill your pocket holes deep enough that the screw head and half the screw shaft buries into the hole. On thinner material, the screw can go through completely while thicker boards will conceal the top half of the screw.

Can I use pocket holes on softwoods and hardwoods?

You can use pocket joinery on virtually any wood material including softwoods, hardwoods, plywood, and more. Just adjust the screw size and angle as needed based on density of the wood. Harder woods may require a shallower angle.

Key Takeaways

– Pocket hole jigs are used to drill angled holes to join boards together with screws in a concealed, strong joint.

– Alternatives like drill guides, knock-off jigs, or making your own allow you to create pocket holes without a jig.

– Other joints like dowels, biscuits, rabbets, and dadoes can also substitute for pocket hole joinery in certain situations.

– Temporary solutions include using angled screws, nails, or adhesives for less demanding projects.

– With some creativity, it’s possible to emulate pocket holes or achieve similar results through myriad alternatives.