Stripping a wire is the process of removing the insulation from the end of an electrical wire. This exposes the inner copper conductor and allows the wire to make electrical contact with connectors, terminals or other wires. Understanding wire stripping and how to do it properly is an essential skill for electricians, DIYers and anyone working with electrical wiring.

Page Contents

Why Strip Wires?

Insulated electrical wires have a plastic or rubber coating that surrounds and protects the inner metal conductor. This insulation prevents contact between wires and prevents shorts or shocks. However, for wires to be connected in circuits and devices, the ends need to contact connectors or other wires. The insulation must be stripped off the tips to allow this contact.

Some common reasons for stripping wire ends include:

- Connecting wires to terminals or posts on devices like switches, outlets and light fixtures

- Splicing wires together with wire connectors

- Attaching wires to the screws or clamps of electrical devices

- Connecting the end of a wire to a circuit board or component

Without stripping the insulation first, the wire ends would not make full electrical contact with the metal surfaces they are attached to. Poor contact could lead to wires loosening over time, intermittent connections or even sparks and electrical fires in severe cases.

How Much Insulation to Strip

It’s important to strip the right amount of insulation off the wire ends – too much or too little could cause problems:

- Too much stripped – Exposes extra bare wire which could touch other wires or conductive surfaces causing shorts.

- Too little stripped – Prevents the wire from making full contact, resulting in loose connections.

The appropriate amount to strip depends on the type of wire connection being made:

| Connection Type | Recommended Strip Length |

|---|---|

| Screw terminal | 5/8 inch |

| Push-in connector | 1/2 inch |

| Binding post | 1/2 to 3/4 inch |

| Wall outlet | 1/2 inch |

| Light fixture terminal | 1/2 inch |

These distances are common recommendations that leave enough bare wire to make a solid connection without exposing excess. Refer to the manufacturer’s instructions for the exact strip length needed for specialty connectors or devices.

Wire Stripping Tools

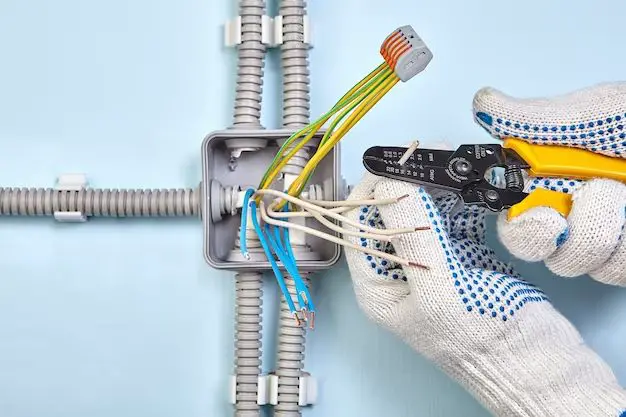

Specialized wire stripping tools are made to quickly and easily remove the right amount of insulation. The main types are:

- Wire stripper pliers – This common style has notched jaws that grip and slice through the insulation when squeezed.

- Automatic strippers – These use spring-loaded blades that strip insulation when the wire is inserted in the right notch.

- Electrician’s scissors – Scissors designed for electrical work can be used to carefully cut and strip insulation.

- Wire brush – A brush with metal bristles helps clean copper conductors after stripping.

Choose a wire stripper suitable for the gauge and type of wire being worked on. Using the right tool makes stripping faster and easier while minimizing the risk of nicking or cutting wire strands.

How to Strip Wire

The technique for stripping wire insulation depends on the tool being used, but generally involves these steps:

- Measure and mark the insulation to be removed. A strip gauge on the tool can help measure.

- Score the insulation around the circumference at the stripping marks.

- Grip the wire beyond the scored mark to avoid damaging the conductor.

- Use the tool to slice through and peel away the section of insulation.

- Carefully trim any stray strands or insulation.

- Clean wire ends with a wire brush to remove residue.

Practice this on scrap wires until you get a feel for using the right pressure and technique to avoid nicking the inner conductors. Be extra careful when working with small, delicate wires.

Precautions for Safe Wire Stripping

These tips will help avoid shorts, shocks and other hazards while stripping wires:

- Make sure all power is turned OFF before stripping any wires that are part of live circuits.

- Wear safety glasses to protect your eyes from flying debris.

- Use sharp, quality tools designed for wire stripping.

- Grip past the area being stripped to avoid cutting strands.

- Double check strip lengths to avoid exposing too much bare wire.

- Don’t rush – stripping takes precision and focus.

- Make clean, straight cuts through the insulation.

Special Situations

Fine Stranded Wires

Fine stranded wire made up of very thin strands are easily damaged when stripped. Special pointed pliers designed for this wire help grip and peel the insulation without cutting strands. Twist connectors may also be needed to keep the fine strands together.

Old Brittle Insulation

Insulation that is very aged can crack and crumble when stripping is attempted. In this case, carefully score the insulation with a utility knife then gently break it free from the wire. Soak any remaining debris in solvent before brushing.

Wires in Tight Locations

Use sharp diagonal cutters to carefully shave the insulation when stripping wires in tight, confined locations. Take extra care not to nick the inner conductors.

Coaxial Cable

Coaxial cable has a center wire surrounded by insulation, a braided shield, and an outer jacket. Special “coax stripper” tools make precise cuts through each layer as needed for connections.

Conclusion

Learning proper wire stripping techniques is crucial for both DIY and professional electrical work. Always use the correct type and size of wire stripper for the job. Measure and mark insulation to be removed based on the wire gauge and connection type. Make clean, straight cuts through the insulation while taking care not to damage inner conductors. With practice, you’ll be stripping wires like a pro in no time.