When working with metal, having the right drill bit is crucial for making clean and precise holes. The wrong drill bit can lead to frustration, wasted time and damaged material. So what are the best drill bits for drilling into metal? Let’s take a look at the top options.

Page Contents

- 1 Best Drills Bits for Metal Overall

- 2 Best for Hardened Steel

- 3 Best for Stainless Steel

- 4 Best for Thick Metal

- 5 Best for Thin Metal

- 6 Best for Cast Iron

- 7 Best CNC Router Bits for Metal

- 8 Drill Bit Materials for Metal

- 9 Drill Bit Styles

- 10 Drill Bit Sizes

- 11 Recommended Speeds and Feeds

- 12 Drilling Techniques

- 13 Conclusion

Best Drills Bits for Metal Overall

If you need a drill bit that can handle most metal drilling jobs, a cobalt steel drill bit is a top choice. Cobalt drill bits are made of high speed steel (HSS) with added cobalt. This gives them excellent hardness and heat resistance. Here are some of the reasons cobalt drill bits are ideal for metal:

- Hardness – The cobalt allows the bits to maintain hardness and avoid premature wear, even under high temperatures.

- Prevents overheating – The hardness also prevents the drill bits from overheating and losing their temper. This allows for smoother, faster drilling.

- Resists abrasion – Cobalt bits are very resistant to abrasive wear, helping them last longer.

Cobalt drill bits can drill through hardened steel, stainless steel, cast iron and other tough metals. They work with hand drills, drill presses and CNC machines. Overall, they provide the best balance of durability, cutting speed and cost for most metalworking applications.

Best for Hardened Steel

Hardened steel, with a Rockwell hardness over C45, is one of the most challenging metals to drill. To drill clean holes in hardened steel, specialized drill bits are needed. Here are top options for hardened steel:

Cobalt Steel Bits

As mentioned above, cobalt steel bits are an excellent choice for hardened steel. Their extreme hardness enables them to cut through the tough material without excessive wear. For best results, choose cobalt bits with extra cobalt content (8% or higher). Slow speeds and light feed rates are also recommended.

Carbide-Tipped Bits

Carbide-tipped drill bits have small carbide inserts brazed to the cutting edges. The carbide provides extreme hardness for drilling abrasive materials like hardened steel. Carbide-tipped bits last significantly longer than standard HSS bits. However, they are also more prone to chipping if used incorrectly. Use these bits with machines only, as the brittle inserts can chip when used manually.

Best for Stainless Steel

Stainless steel’s high strength and gummy chips make it difficult to drill. Special drill bits are needed to avoid work hardening and built-up edge. Here are recommended bits for stainless steel:

Cobalt Bits

Again, cobalt steel bits are a top choice. Their hardness enables them to drill stainless steel with minimal wear or work hardening. Make sure to use high quality bits, as cheaper cobalt bits may not hold up. Slow speeds, moderate feed rates and plenty of lubricant will help them last longer.

Titanium Bits

Titanium coated drill bits are uniquely suited for stainless steel. The titanium coating provides hardness while resisting the gummy buildup that plagues other drill bits. Built-up edge is minimized, allowing for faster, cleaner cuts. Titanium bits are a pricier option, but can dramatically improve results in stainless steel.

Best for Thick Metal

Drilling through thick, heavy metal requires specialized drill bits. Here are the top options for thick metal:

Cobalt Step Bits

Cobalt step bits (also called uni-bits) have tapered cutting edges that gradually increase in diameter. This allows a single bit to drill holes with a wide range of diameters. Step bits are extremely useful for drilling large diameter holes in thick metal. Make sure to choose bits with cobalt content for best performance in metal.

Indexable Insert Bits

Indexable insert bits have removable carbide or ceramic inserts that can be replaced when worn or damaged. Multiple indexes around the bit let you rotate the insert for a fresh cutting edge. Indexable bits are ideal for drilling big holes in thick metal, as well as abrasive materials like cast iron. They provide excellent cutting speed with minimal wear.

Best for Thin Metal

Drilling sheet metal and thin metal stock requires different techniques to avoid distortion. Here are the best drill bits for thin metal:

Standard Twist Bits

Standard high-speed steel twist bits work well for routine drilling in thin metal. Use a stepped bit or Brad point bit for clean entry. Maintain slow speeds and low feed pressure. Clamp the metal securely and use a backing block if possible.

Left-Hand Bits

Left-hand spiral bits cut in the opposite direction to standard bits. This counter-clockwise cutting action helps prevent thin metal from warping or catching on the bit. Lubricant will also help reduce binding and tearing.

Best for Cast Iron

Cast iron’s brittle, abrasive nature calls for specific drill bits to avoid premature wear. Here are top choices:

Titanium Bits

As mentioned for stainless steel, titanium coated bits are highly effective in cast iron. The slick titanium coating resists fouling, while the hardness stands up to cast iron’s abrasiveness. These bits stay sharper longer for smooth, fast drilling in cast iron.

Cobalt Bits

The extreme hardness of cobalt steel makes it well-suited for cast iron drilling applications. HSS cobalt bits hold their edge better to drill faster and cleaner through brittle cast iron. High cobalt content (8% or more) provides maximum abrasion resistance.

Best CNC Router Bits for Metal

CNC routers require specialized bits for metalwork. Here are the most suitable CNC bits for metal:

Coated Solid Carbide Bits

Solid carbide bits with titanium aluminum nitride (TiAlN) coating are often used for CNC metal routing. The carbide provides hardness and edge retention. The coating reduces friction and resists metal buildup. These bits hold up to high speeds and feed rates from CNC machines.

Multi-Flute Bits

Multi-flute carbide router bits, like quad-flute or variable-helix bits, are also common. The additional flutes provide sharper, faster cutting and efficient chip removal. This helps maintain cutting speed and bit life when used on CNC routers.

Drill Bit Materials for Metal

Drill bits for metal are available in several materials. Each has pros and cons:

| Material | Best For | Pros | Cons |

|---|---|---|---|

| High-Speed Steel (HSS) | Most general purpose metal drilling | Good hardness; low cost | Prone to overheating; moderate wear resistance |

| Cobalt HSS | Hardened steel; abrasive metals | Extreme hardness; excellent heat/abrasion resistance | More expensive than standard HSS |

| Carbide-Tipped | Hardened steel; thick metal | Very hard; impact/abrasion resistant | Brittle; prone to chipping; higher cost |

| Titanium-Coated | Stainless steel; cast iron | Slick coating; resists metal buildup | Coating can wear over time |

Drill Bit Styles

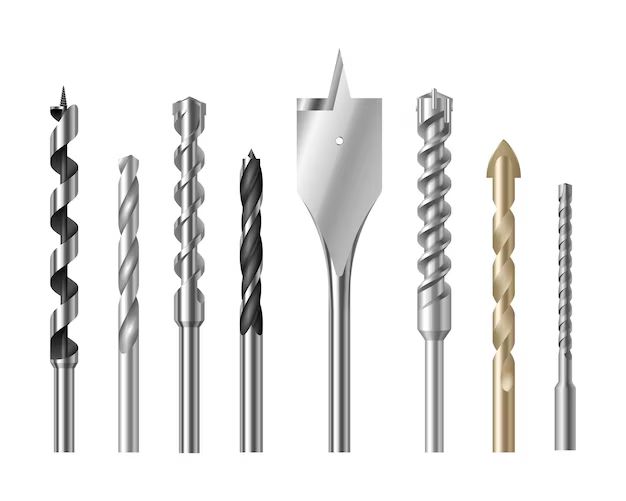

Drill bits for metal are available in various styles. The most common include:

- Twist – The most common drill bit type, with a helical groove wrapping around the conical body. Universal style suitable for hand and machine drilling.

- Brad Point – Pointed tip with spurs around the perimeter for clean entry into metal. Reduces walking and tearing out backside of holes.

- Step/Uni-bit – Single bit with gradually tapering steps for drilling a range of hole sizes. Good for thick metal.

- Indexable Insert – Replaceable carbide inserts provide durability when drilling large, deep holes. Mostly used in machining.

Drill Bit Sizes

Metal drill bits are measured based on the diameter of holes they can drill. Common sizes include:

- Small – up to 1/8″ diameter

- Medium – 1/8″ to 1/4″ diameter

- Large – 1/4″ to 3/8″ diameter

- Extra-large – over 3/8″ diameter

Miniature bits with diameters under 1/16″ are also available for drilling very small holes in thin metal. Larger bits over 1/2″ diameter are used with machine tools for thick metal drilling. Match your bit size to the intended hole size for best accuracy.

Recommended Speeds and Feeds

Proper drill speeds and feeds are important when working with metal. Follow these general guidelines:

Speed

- Softer metals – Faster speeds around 2500 RPM

- Hard/tough metals – Slower speeds around 800 RPM

- Thin metals – Slow speeds below 1500 RPM

Feed Rate

- Soft metals – Faster feed rate

- Hard metals – Slower feed rate

- Thin metals – Light feed pressure

Always start at a slower speed and light feed rate, increasing gradually as needed. Use plenty of lubricant as well. Let the drill do the work, not too much pressure.

Drilling Techniques

Proper technique is key for clean, accurate holes in metal. Here are some tips:

- Use cutting fluid or oil to lubricate and cool drill bit

- Clamp workpiece securely to prevent vibration/slipping

- Start with centering punch or spot drill to guide bit

- Peck drill deep holes to clear chips and prevent binding

- Back up thin metal with wood block to prevent distortion

- Sharpen bits regularly for maximum cutting efficiency

Taking your time and using the right techniques will lead to better hole quality in metal. Rushing the process with dull bits, too much speed, and insufficient lubrication will cause problems.

Conclusion

Drilling metal requires drill bits engineered for hard, abrasive materials. Cobalt steel bits are top performers for most metals, providing hardness and heat resistance. Carbide-tipped, titanium-coated and indexable insert bits are other good options. Using the proper bit for your metal type, along with recommended speeds and best practices, will ensure fast, accurate and clean holes.