Page Contents

Can You Glue PVC to ABS?

It is generally not recommended to glue PVC and ABS pipes together. PVC (polyvinyl chloride) and ABS (acrylonitrile butadiene styrene) are two different types of plastic that require different types of glue. Using the wrong glue can result in a weak bond that is prone to leaking or separating.

However, in some cases it may be necessary to join PVC and ABS, such as when combining existing pipes made of different materials. With the proper adhesive and preparation, PVC and ABS can form an adequate bond for low or moderate pressure applications. However, for critical high-pressure systems, it is best to use the same material for all pipes and fittings.

Challenges of Gluing PVC to ABS

There are a few key challenges when attempting to glue PVC and ABS together:

- Chemical incompatibility – PVC and ABS do not chemically bond to each other with standard glues.

- Different expansion/contraction rates – PVC and ABS expand and contract at different rates with temperature changes, potentially weakening the joint.

- Difficult surface preparation – The smooth surfaces of PVC and ABS can be difficult to rough up for gluing.

Standard PVC and ABS pipe cements only bond to their intended material. The glue will either not cure properly or will create a weak bond when used on the wrong pipe material. Solvent cements work by actually melting and fusing the plastic pieces together, but PVC and ABS require different solvents.

The different expansion rates of PVC and ABS mean the joint may gradually separate over time as the pipes expand and contract at different temperatures. This can lead to leaks or failure.

And unlike materials like wood, plastic pipes are very smooth, which can make it hard to rough up the surface for the glue to mechanically adhere to.

Adhesives for Joining PVC to ABS

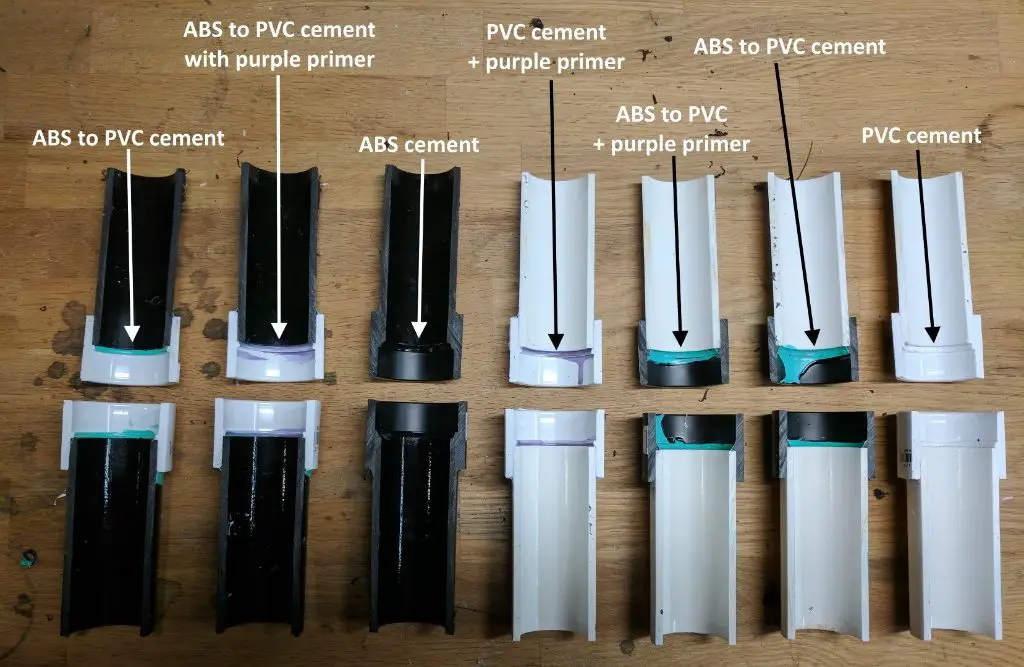

While standard PVC and ABS cements won’t work, there are a few adhesive options that can be used to glue PVC and ABS together:

PVC to ABS Transition Cement

PVC/ABS transition cement is specifically designed to bond PVC and ABS together. It contains a blend of solvents and additives that allow it to break down and fuse both surfaces. This type of cement is readily available from most hardware stores and plumbing suppliers.

Transition cement provides a decent bond between PVC and ABS and can be used for low or moderate pressure applications. It is generally not recommended for hot water, pressure, or chemical lines. Follow the application directions for proper joint strength.

Multi-Purpose Adhesives

Some multi-purpose adhesives like epoxy or methyl methacrylate can create a good bond between PVC and ABS surfaces. These adhesives work by mechanically adhering to the pipe rather than fusing/melting the plastic.

Epoxy creates a very strong and rigid bond, while MMA adhesives like PVC/ABS glue are more flexible. However, surface preparation is very important with these adhesives to rough up and clean the PVC and ABS prior to application.

PVC Pipe Primer and ABS Cement

Some plastic pipe installers have reported success joining PVC and ABS by first applying PVC primer to both surfaces, allowing to dry, and then applying ABS cement over the primer.

The PVC primer etches and softens both surfaces, while the ABS cement fuses the ABS side of the joint. However, this method is not recommended by manufacturers and results may be inconsistent. Thorough surface prep and following the ABS cement directions is critical.

How to Glue PVC to ABS

Here are the general steps for gluing PVC to ABS with transition cement, epoxy, or MMA adhesive:

- Sand and clean all surfaces – Rough up PVC and ABS with coarse sandpaper and wipe away any dirt or residue with a clean rag.

- Dry fit pipes – Test fit the PVC and ABS together without cement to ensure proper alignment and a tight fit.

- Apply adhesive – Use a high-quality transition cement, epoxy, or MMA adhesive, applying a thin layer to both surfaces according to directions.

- Assemble joint – Quickly assemble pipes with a slight twisting motion to spread the glue. Hold in position firmly for 30 seconds.

- Support joint – Use clamps, tape, or additional bracing to support the joint while the adhesive cures. Do not handle or stress the joint.

- Allow to fully cure – Allow several hours or overnight for adhesive to fully cure before pressure testing.

Avoid getting excess cement, epoxy, or adhesive on the interior of the pipe to prevent contamination. Wear gloves and safety glasses when working with chemical adhesives.

How Strong is a PVC to ABS Joint?

When glued properly with an appropriate adhesive, a PVC to ABS joint can potentially be very strong. However, strength depends heavily on the specific adhesive used, pipe sizes, and precision gluing the joint.

Here are some general strength characteristics:

- PVC/ABS transition cement – Approx. 500 psi strength when allowed to cure fully

- 2-part epoxy – Up to ~2,000 psi, but very rigid and more likely to crack under pressure

- MMA adhesives – Around 2,000 psi strength when prepared correctly

While testing shows these adhesives can produce very strong PVC to ABS bonds, there are several important caveats:

- Bond strength decreases as pipe size increases due to greater surface area

- Failure often occurs from improper surface prep or application of adhesive

- Strength can deteriorate over time from expansion/contraction stresses

For these reasons, glued PVC to ABS joints should only be used for low or moderate pressure applications. For any critical water, chemical, or hot water plumbing connections, using the same pipe material throughout is strongly advised over joining dissimilar plastics.

Examples of When to Glue PVC to ABS

Here are some common examples of when it may be useful or necessary to glue PVC to ABS pipes:

Drainage Joints

Gluing PVC to ABS is most often done on drainage pipes, typically non-pressure applications like gutter downspouts, drain lines, or vent stacks. Transition cement creates solid joints for these low-stress uses.

Repairing Existing Pipes

When attempting to splice a repair piece into an existing ABS or PVC plumbing line, transition glue can join the new and old plastic to avoid replacing the entire run.

Mixing Plastic Types

Sometimes ABS and PVC are mixed in the same system, for example ABS drains and PVC vent pipes. Transition cement is useful here since standard ABS or PVC glues won’t work between both materials.

Emergency Leak Repairs

PVC and ABS can be joined as a temporary emergency fix for leaks in less critical systems until a more permanent repair is made. The joint may not hold long term but can stop the leak.

Precautions When Gluing PVC to ABS

While PVC and ABS can be glued together, it’s important to take the following precautions:

- Surface preparation is critical – Thoroughly sand and clean joining surfaces

- Avoid use on pressurized water or hot water lines

- Allow full cure time before stressing joint – 12-24 hours minimum

- Support joint firmly with tape, clamps or bracing until cured

- Test at low pressure, gradually increasing to check for leaks

- Expect shorter service life than joints of same material

- Not approved for potable water or food contact applications

Only use transition cement or other adhesives specifically designed for PVC and ABS. Avoid any bending or torsional stress on the joint. Allow time for thorough curing rather than rushing the repair. And confirm no leaks before returning any system to full normal pressure.

Other Options for Joining PVC and ABS

If gluing PVC to ABS is not an option, here are a couple other alternatives:

Transition Couplings

There are special transition fittings molded from both ABS and PVC allowing the two materials to be joined with standard solvent cement on their respective sides. These couplings can adapt pipe sizes as well.

Mechanical Couplers

Mechanical couplers join pipes without cement or glue. Metal clamping rings compress rubber sleeves around each pipe to create a seal. These can join any pipe material combination, including PVC and ABS.

Conclusion

Gluing ABS and PVC together can be done in certain circumstances using the proper transition cement or other multi-material adhesive. This allows PVC and ABS pipes to be adapted or repaired without replacing entire ABS or PVC system runs.

However, for critical applications, it is still best practice to use the same pipe material throughout the system. The joint between ABS and PVC is less reliable than consistently using PVC or ABS. But for temporary low pressure uses, a PVC to ABS cemented joint can provide an adequate solution.