When it comes to determining the optimal size for a cross cut sled, there are a few key factors to consider. The main purpose of a cross cut sled is to provide a stable, flat surface to push your workpiece through the blade while cutting cross grain pieces on a table saw. Having the right size sled for your table saw and workpieces will ensure accurate, safe, and repeatable cuts.

Page Contents

What size table saw do you have?

The size of your table saw will dictate the maximum size your cross cut sled can be. Most contractor style table saws have a 20-27 inch deep rip capacity. Cabinet saws generally range from 25-30+ inches of rip capacity. You’ll want your sled to be narrow enough to easily fit in the rip fence guides without binding or getting stuck.

It’s recommended to make your sled about 1-2 inches narrower than the available rip capacity of your saw. This allows some wiggle room for adjustment and prevents potential binding issues. For example, if your saw has a 27 inch rip capacity, making the sled 25 inches wide would be a good fit.

Table Saw Rip Capacities

| Table Saw Type | Typical Rip Capacity |

|---|---|

| Contractor/Portable | 20-27 inches |

| Cabinet | 25-30+ inches |

What are you cutting?

The next thing to factor is the size of your workpieces. Your sled needs to be large enough to fully support the size of stock you’ll be cutting for your projects.

For smaller workpieces like narrow rips or crosscutting boards up to 8 inches wide, a standard 24 inch crosscut sled is usually sufficient. But if you routinely work with wider stock, make doors, cut sheet goods down to size, or do larger projects you’ll want a larger sled in the 28-32 inch range.

The sled length should be enough so the workpiece is fully supported past the back edge of the saw blade through the entire cut. A good rule of thumb is to make it 6-12 inches longer than the longest board you expect to crosscut.

Recommended Sled Size by Workpiece Width

| Workpiece Width | Minimum Sled Size |

|---|---|

| Narrow rips, up to 8 in. | 24 inches |

| 8 – 12 in. boards | 26 – 28 inches |

| Wider stock, large projects | 30+ inches |

Sled width – finding the sweet spot

When deciding on width, you generally want to find the maximum size that fits your saw while still being compact enough to maneuver and store easily. A few inches smaller than the full rip capacity is ideal.

Too narrow, and the sled won’t provide enough support for wider boards, limiting its usability. Too wide creates handling problems – a bulky sled that’s awkward to move around the shop and difficult to store.

The sweet spot for most home shops is right around 26 inches wide. This allows you to rip up to 12 inch stock with full support, while still being nimble enough to easily move the sled onto and off of the saw.

Sled length – provide ample workpiece support

For length, err on the side of being longer than your workpieces to provide rear support throughout the cut. Anything shorter leaves your material unsupported and unstable as it passes the blade, risking binding and inaccurate cuts.

Most DIYers find a length between 24 – 36 inches to be ideal for general use. This gives you 6 – 12 inches of rear support when cutting common board lengths in the 12 – 24 inch range.

If you work exclusively with longer stock or sheets, build your sled even longer. Up to 48 inches is suitable for cuts on 8 foot long boards or breaking down full sheets.

Additional design considerations

In addition to size, there are some other factors that impact the usability of a crosscut sled:

Rather than maxing out capacity, leave some margin

Even if your saw can rip 30 inches, making a 30 inch wide sled is asking for trouble. A few inches less creates some margin so the sled rides smoothly in the tracks without binding.

Support the entire workpiece

The sled should be long enough to provide solid support underneath the entire workpiece, not just at the front edge where the blade meets the cut.

Smooth moving

Wax the underside of the sled to help it glide smoothly over the table surface without sticking.

Secure the workpiece

Add clamps, stops, and hold downs to lock the workpiece in place during the cut.

Easy storage

Make sure your sled design allows it to be easily stored off the saw when not in use. Some mount vertically on the wall. Carts with wheels also work great.

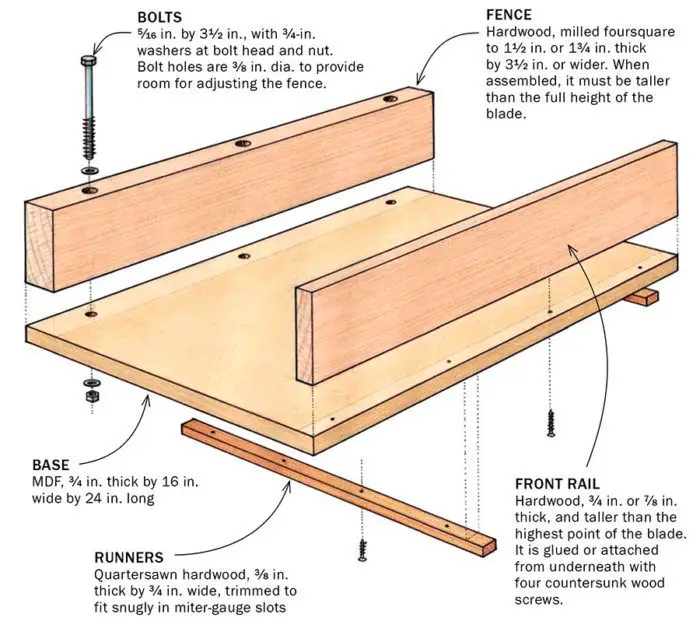

Materials and construction

Use plywood or MDF at least 3/4″ thick for the base – avoid solid wood that can warp. Hardwood edging around the perimeter helps reduce tear out and friction while adding durability.

The front fence should also be a stable, straight material. Many DIY sleds use a 2×4 screwed to the front edge to register the workpiece squarely.

Safety considerations

Since you’ll push this sled through the spinning blade by hand, safety is critical in the design.

Zero clearance at the blade

Cut a slot in the sled base that matches your blade height and provides zero side-to-side clearance around the blade. This prevents tear out on the underside of the workpiece.

Stable and flat

Any flexing, cupping, or twisting as you cut can lead to binding and kickback. Use thick, flat plywood.

Smooth bottoms

Wax or adhesive plastic slides underneath the sled reduce friction and sticking on the tabletop as you cut.

Precise fence

The guide fence must be square and parallel to the blade to ensure straight, accurate cuts.

Hand protection

Don’t allow your hands to get near the blade path during cuts!

Conclusion

Finding the ideal cross cut sled size depends on your particular saw and workpieces. While large cabinet saws allow huge sleds up to 32 inches wide and 48 inches long, most DIYers will find a slightly more compact 24-28″ wide by 30-36″ long sled provides the versatility to safely tackle most common cuts.

The key is ensuring your sled fully supports the workpiece while not being dangerously bulky. Allowing a couple inches of margin under your saw’s max rip capacity is ideal. Smoothing out the glide across the table and building in safety features are also critical.

With the right sled dimensions and design considerations addressed, you’ll be able to achieve years of enhanced, precise crosscutting on your table saw.