Cutting off sway bar links is a common task when working on vehicle suspensions. Sway bar links connect the sway bar to the control arms or struts. Over time, the ball joints and bushings on sway bar links can wear out, causing excessive play, clunking noises, and poor handling. When this happens, the best solution is to replace the sway bar links. However, to remove old sway bar links, you first need to cut them off. Having the right tool for this makes the job much easier. So what is the best tool for cutting off sway bar links? There are a few good options that each have their advantages.

Page Contents

What are Sway Bar Links?

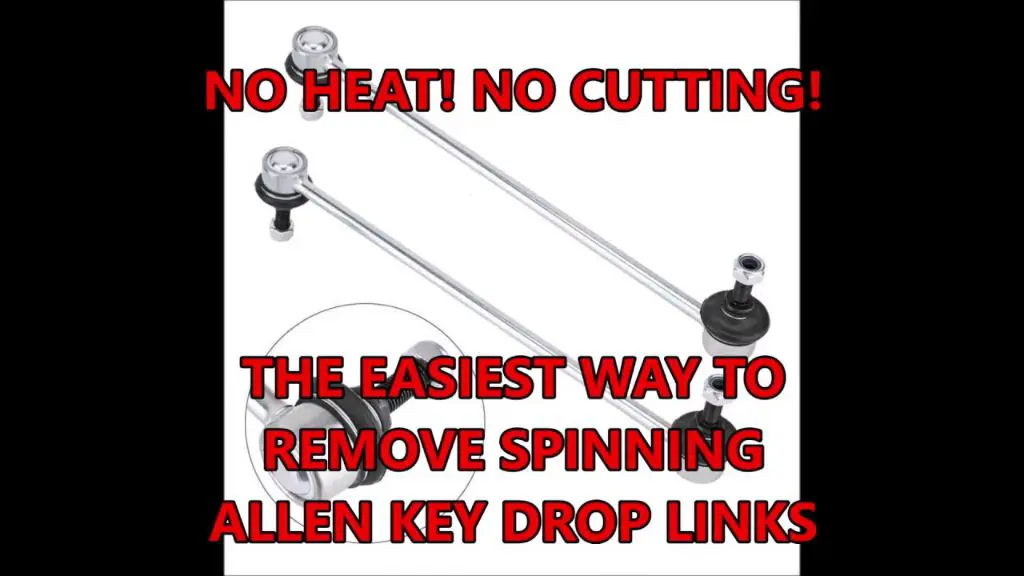

Sway bar links are short arms that connect the sway bar to the suspension on each side of the vehicle. The sway bar spans the width of the vehicle and works to reduce body roll in corners. As the body leans, the sway bar twists and transfers force to the opposite side to counteract the leaning motion. This improves handling and stability.

The sway bar links allow this motion to transfer between the sway bar and suspension. Most sway bar links have ball joints at each end to allow angle changes as the suspension travels up and down. Rubber or polyurethane bushings around the ball joints cushion the motion and suspension noise.

Over time, the ball joints and bushings wear out, resulting in looseness, clunking, and poor handling. Replacing worn out sway bar links restores proper suspension function and handling. But first, you need to cut off the old links to remove them.

Maneuverability and Access

One of the challenges of cutting off sway bar links is getting tools up to the links. Sway bars are located deep in the wheel wells, often obstructed by suspension and brake components. This means you need tools that are compact and maneuverable enough to fit in the tight space. An ideal cutting tool will have a short profile that allows it to fit around obstructions.

Longer tools like hacksaws can be difficult to position correctly. So compact tools like mini bolt cutters tend to work better. Cordless angle grinders are also very maneuverable for getting on top of sway bar links. Choose a small 4.5” or 5” angle grinder for best access.

Make sure to use the proper wheel chocks and jack stands to safely raise and support the vehicle. This will provide the access you need to get cutting tools onto the sway bar links. Raising just one side of the vehicle at a time will allow the best room to work.

Cutting Strength

Sway bar links are made from rugged steel and are designed to handle road impacts and suspension forces. So they are very strong parts. Cutting through sway bar links takes significant cutting force and strength. Any tool you choose needs enough mechanical advantage and leverage to cut through the thick steel.

Mini bolt cutters can provide the needed cutting force in a compact tool. A quality 14” or 18” mini bolt cutter like those made by GEARWRENCH or Crescent can cut through sway bar links. Full size 24” bolt cutters also work if space allows.

For cordless angle grinders, use a 4.5” grinder minimum. The most power you can get is best, as cutting will require a lot of battery life. A brushless motor angle grinder like the Milwaukee 2763-20 provides excellent power-to-size ratio. Use cut-off wheels for the fastest cutting action.

Safety Gear

Cutting off metal suspension components will send sparks and shards flying. Be sure to wear proper safety gear when cutting off old sway bar links. At minimum, you should wear eye protection and thick work gloves. The eye protection guards against flying debris and shards getting in your eyes. Gloves protect your hands from sharp burrs on the cut ends.

A long sleeve shirt is also a good idea to protect your arms from sparks and metal fragments. Closed toe shoes and hearing protection are also recommended when using loud power tools like angle grinders. Have a fire extinguisher on hand in case any sparks ignite materials under the vehicle.

Cutting Methods

With the right cutting tool, there are a couple methods that work well to cut off sway bar links.

For bolt cutters, position the joint in the center of the cutting blades. Take care to properly align the blades on either side of the link. Slowly squeeze the handles with even pressure and let the tool do the work. Don’t twist or wiggle the handles, as this can damage the cutting edges. Be patient and make repeated full cuts to slowly notch through the steel.

With a compact angle grinder, make sure the cut-off wheel is rated for cutting metal. Position yourself with good leverage and balance. Keep the spinning wheel perpendicular to the link and gently feed it into the steel. Let the wheel slowly cut through the metal, being careful not to bend the disc. Make shallow cuts if needed versus trying to cut through in one pass. Watch for binding which can overload the wheel. Grind/cut from both sides to finish separating the link.

Other Cutting Options

While mini bolt cutters and small angle grinders tend to work best, here are a few other tools that can also cut through sway bar links:

– Full size bolt cutters – The long handles provide more leverage for cutting thick steel. But the large size limits maneuverability.

– Reciprocating saw – Can work in tight spaces. But the blades may bind or break when trying to cut thick sway bar steel.

– Mini hacksaw – Compact like a reciprocating saw but slower cutting requiring patience. The thin blades are prone to breaking.

– Oscillating tool – Small size allows getting into tight areas. But the fine oscillating motion isn’t ideal for cutting thick hardened steel.

– Chisel – Can chip/shatter the metal when struck with a hammer. But this takes a lot of effort and metal shards can fly dangerously.

While these tools might work, the mini bolt cutters and compact angle grinder are the cleaner and more efficient choices for cutting off old sway bar links.

Replacing Sway Bar Links

Once you’ve cut off the original sway bar links, removing any remaining studs or balls joints will allow the installation of new replacement links. Be sure to get links that exactly match the original ones. Forging alloy steel links will provide the most rugged and long-lasting replacement.

New nuts and bolts will usually be needed to attach the new links to the sway bar and control arm. Torque all hardware to the vehicle manufacturer’s specs. Lubricate any ball joints on the new links per the instructions. As a final step, have the vehicle suspension alignment checked to ensure proper tracking after working on the steering linkage.

Replacing worn out sway bar links and getting an alignment will restore responsive handling and control to your vehicle. The job will be much easier by having the right tools to cleanly cut off the original links. Compact bolt cutters and small angle grinders allow quick work of cutting off sway bar links even in tight spaces.

Conclusion

Cutting off stubborn sway bar links can be a challenge without the proper tools. Long reach and maneuverability are required to access the links mounted deep within the suspension. Mini bolt cutters and compact 4.5” angle grinders are the best options for getting in and cutting off links. Their short size allows them to fit around suspension and brake components.

Look for mini bolt cutters in the 14” size range to provide enough leverage and cutting force in tight quarters. For angle grinders, choose a model with a brushless motor to provide as much power as possible in a small grinder. Proper protective gear like gloves and eye protection are a must when cutting off metal suspension parts.

Equipped with the right cutting tools, you can make short work of removing worn out sway bar links. New links are then easily installed to restore proper suspension function and handling performance. Your vehicle will be back to controlling body roll and cornering flat in no time.