HEPA filters and HEPA vacuums are both designed to trap tiny particles and help improve indoor air quality. But there are some key differences between the two.

In short, a HEPA filter is a type of filter that can be used in various appliances and systems to remove small particles from the air. A HEPA vacuum is a vacuum cleaner that uses a built-in HEPA filter system to trap particles during the vacuuming process.

Here is a quick overview of the key differences:

| HEPA Filter | HEPA Vacuum |

|---|---|

| Filter that can be used in various appliances/systems | Type of vacuum cleaner with built-in HEPA filtration |

| Traps particles as air passes through the stationary filter | Traps particles as vacuumed air passes through the filter |

| Must be replaced periodically | Filter may need replacement over time |

| Effectiveness depends on proper installation/maintenance | Self-contained particle removal system |

Now let’s take a more in-depth look at HEPA filters vs. HEPA vacuums.

Page Contents

What is a HEPA Filter?

A HEPA filter is a type of pleated mechanical air filter that satisfies certain standards of efficiency at trapping very small particles. HEPA stands for “high efficiency particulate air.”

The key criteria for a HEPA filter are:

– It must remove at least 99.97% of particles that have a size of 0.3 μm at a specified flow rate.

– It must have an efficiency rating of 12 or higher on the IEST (Institute of Environmental Sciences and Technology) standard scale. This measures fractional particle removal efficiency for particle sizes between 0.1 – 0.2 microns.

Some key applications and uses of HEPA filters include:

– Air purifiers: Portable HEPA air purifiers use a fan to force air through a HEPA filter to remove airborne particles. This filtered clean air is then blown back out.

– HVAC systems: HEPA filters can be installed as part of central heating, ventilation and air conditioning systems to purify the air in whole buildings.

– Vacuum cleaners: Some vacuums use HEPA filters to trap dust and allergens before exhausting the air back out.

– Hospitals: HEPA filters are critical in hospital isolation rooms and operating rooms to control the spread of infectious diseases.

– Manufacturing: HEPA filters help create ultra clean environments for certain manufacturing processes.

– Nuclear sites: HEPA filters help prevent the escape of radioactive particles at nuclear sites.

The filtration process works as contaminated air is forced through the maze-like structure of densely packed fibers inside the filter. Particles become trapped in the fibers and cannot pass through, while clean air emerges from the other side.

Over time, the accumulated particles start to increase resistance to airflow, indicating the filter needs replacement. Proper installation and maintenance are key to ensuring HEPA filters perform as designed.

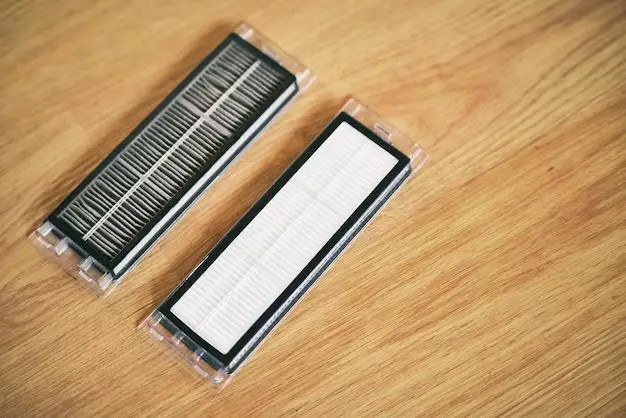

HEPA Filter Construction

There are a few key elements that make up an effective HEPA filter:

– Fiberglass or similar media: The filter media features very fine glass fiber strands or similar material woven together. This creates a matrix of ultra-fine pores that trap particles.

– Pleated design: The media is folded into pleats to maximize surface area. This increases airflow capacity.

– Sealing frame: Polyurethane or similar material forms a tight seal around the periphery of the filter to force air to only flow through (not around) the media.

– Support structure: Sheets of media are spaced apart and affixed to a structural support that allows air to permeate while maintaining the media’s shape. Supports are often made of cardboard, plastic or metal.

While the above describes the most common HEPA filter design, there are also some alternative constructions. For example, some filters use a series of stacked media disks rather than a single pleated sheet.

HEPA Filter Sizes

HEPA filters come in a wide range of physical sizes to fit different applications. Some common standard sizes include:

– 5″ x 8″ x 1″ – Small filters for portable air cleaners

– 12″ x 12″ x 1″ – Medium filters for HVAC systems and air purifiers

– 24″ x 24″ x 5.5″ – Large HVAC filters

– 19.5″ x 19.5″ x 11.5″ – Extra large HVAC and cleanroom filters

Non-standard sizes are also widely available. Filters meant for HVAC systems usually come with a cardboard frame holding the media in place. The frame slides into racks or tracks inside ductwork.

While filters come in different physical sizes, the filtering media itself must meet the same HEPA standards of efficiency regardless of dimensions. Manufacturers use consistent materials and construction methods to achieve filtration performance across their product lines.

HEPA Filter Ratings

Beyond just meeting the baseline criteria to qualify as HEPA, filters are also rated based on their efficiency and capacity.

Two key ratings are:

– Particle removal efficiency: Rated on the IEST test scale. Higher ratings mean the filter is more efficient at trapping particles in the crucial sub-micron range.

– Recommended airflow capacity: Expressed as cubic feet per minute (CFM). Indicates the airflow volume capacity the filter is designed and tested for.

High capacity HEPA filters have ratings of 1,000 CFM or more. Efficiency ratings of 15+ on the IEST scale demonstrate exceptional filtration performance.

HEPA Filter Limitations

While HEPA filters offer excellent filtration, they do have some limitations:

– Cannot trap very small particles like certain viruses without additional filtration stages.

– Accumulated particles increase airflow resistance over time.

– Effectiveness depends heavily on proper installation within HVAC systems or other tightly sealed frames. Any leaks or bypass means unfiltered air is released.

– Must be replaced periodically to avoid restrictive airflow and potential mold growth.

– Generally higher upfront costs than lower-rated filters, plus ongoing replacement costs.

– Disposal of used filters must be handled carefully to avoid release of trapped bioaerosols.

What is a HEPA Vacuum?

A HEPA vacuum is a specialized type of vacuum cleaner containing filters that capture at least 99.97% of particles 0.3 microns and larger. This allows it to trap fine particles that ordinary vacuum cleaners simply recirculate back into the air.

The key defining features of true HEPA vacuums are:

– Built-in HEPA filtration as the last stage before the cleaned air is expelled. This ensures no particles bypass the filter.

– Fully sealed construction and gaskets to prevent any unfiltered leaks.

– Designed airflow path pulls particles directly into the filter.

– May have additional filters before the HEPA stage to handle larger debris and extend HEPA filter life.

Any vacuum can only be marketed as “HEPA” if it meets stringent filtration efficiency standards. Proper testing and certification protocols must be followed.

Some additional technologies commonly found in HEPA vacuums include:

– Advanced internal suction design and fan performance. This is required to handle the airflow resistance created by multi-stage filtration.

– Bristled brushrolls, strong suction, and sealed edges to effectively pull in particles and get them into the filtration flow.

– High-quality gaskets and tight manufacturing tolerances in crucial areas to eliminate leaks.

– Antimicrobial treatments on filters and other interior surfaces to inhibit mold and bacteria growth.

Uses of HEPA Vacuums

HEPA vacuums excel at trapping fine particles you may not want circulating in the air you breathe, such as:

– Dust mites and debris

– Pet dander and hair

– Pollen, mold spores, bacteria

– Smoke and soot particles

– Viruses and bioaerosols

This makes them well suited for:

– Allergy sufferers

– Pet owners

– Anyone wanting cleaner indoor air

– Remediation of contamination like mold or lead

– Cleaning up after fires or floods

People with respiratory issues rely heavily on HEPA vacuums to help control particulates that could aggravate their conditions.

They are also commonly used in medical settings to control and contain biological contaminants.

Types of HEPA Vacuums

There are a few main categories of HEPA vacuums:

– Canister vacuums: Canister style with the motor and filtration in a cylinder unit pulled on wheels. Provides strong suction through a long hose and cleaning heads.

– Upright vacuums: Motor and filters are in an upright unit that can stand on its own while in use. Direct floor cleaning from the main unit along with hose attachments.

– Central vacuums: Built-in filtration system exhaustion and ducting installed in a building. Vacuuming inlet ports placed throughout the building connect to the central unit via internal ductwork.

– Stick vacuums: Compact and lightweight stick-shaped units providing cordless convenience. Rechargeable battery-powered. Lower runtime than canister and upright models.

– Handheld vacuums: Very compact models operated manually for small cleanups. Lower power ratings than full-size models.

– Commercial vacuums: Extra durable HEPA models meant for heavy professional/industrial use.

Some models may combine features like upright units with detachable handhelds.

HEPA Vacuum Filtration Stages

HEPA vacuums pull particles through multiple stages of filtration:

1. Pre-motor filter: Catches large debris before it can reach and damage the motor. Usually a foam or mesh filter cleanable by the user.

2. Primary filter: Pleated medium filter to stop smaller particles from passing through to the HEPA filter and clogging it. May be permanent or cleanable filter.

3. HEPA filter: The key HEPA media that captures the tiniest particles. Needs replacement over time.

4. Additional exhaust filter: Final filter at the clean air exhaust before particles exit the vacuum. Further protection against particles bypassing previous stages. May be a secondary HEPA filter.

This staged filtration allows each component to be optimized for its purpose. It greatly extends the functional lifespan of the all-important HEPA filter media.

HEPA vs Standard Vacuums

Here are some key differences between HEPA vacuums and standard vacuums without advanced filtration:

| HEPA Vacuum | Standard Vacuum |

|---|---|

| Traps and retains particles as small as 0.3 microns | May only trap larger particles, recirculating small particles back into the air |

| Multi-stage filtration system | May lack critical filtration components |

| Fully sealed casing prevents unfiltered air bypass | Can have air leaks reducing filtration effectiveness |

| Removes allergens, mold, smoke, viruses | Not as effective for sensitive filtration tasks |

| Improves indoor air quality | Minimal benefit for indoor air quality |

| Required for highly controlled environments | Unsuitable for medical, cleanroom uses |

| Typically more expensive | Lower upfront cost |

While HEPA vacuums have a higher upfront investment, the benefits can be worthwhile for many users – especially allergy sufferers. With proper maintenance they provide superior long term air filtration.

Conclusion

Key Takeaways

– HEPA filters and HEPA vacuums both remove extremely small particles from air, but have distinct roles.

– HEPA filters are components that filter air flowing through mechanical systems and appliances. HEPA vacuums are self-contained machines with built-in HEPA filtration.

– While a HEPA vacuum uses a HEPA filter, the vacuum includes additional functionality beyond just the filter itself. This includes particle pickup, internal airflow control, and multi-stage filtration.

– HEPA filters require proper installation and occasional replacement. HEPA vacuums are engineered as total systems to automatically direct particles through layered filtration.

– Both technologies are critical for controlling fine particulates and creating highly purified air. Certain limitations exist, but overall HEPA filters and vacuums can dramatically improve air quality.

When choosing air purification solutions, consider how standalone filtration and embedded HEPA filters can work together as part of a complete system tailored to your indoor environment. With the right combination of quality filters and vacuums maintaining clean air is achievable in residential and commercial settings.