Levels are important tools used in construction and home improvement projects to ensure structures, surfaces, and objects are level and plumb. The two main types of levels are regular levels and torpedo levels. Both serve the same basic purpose of helping establish horizontal and vertical alignment, but they have some key differences in their design and intended use.

Page Contents

What is a Regular Level?

A regular level, also known as a spirit level or bubble level, is the most common type of level. It consists of a sealed vial that is slightly curved and contains a small air bubble floating in colored alcohol or ether. The vial is set inside a rigid frame that has a flat bottom designed to sit flush on the surface being leveled.

When the vial is placed on a perfectly horizontal surface, the bubble will align in the center of the curvature. If the surface is not level, the bubble will float towards the higher end. The user simply adjusts the surface until the bubble is centered again. This allows the regular level to accurately determine level, plumb or inclined planes in one axis.

Regular levels come in a variety of lengths, with the most common being 2 feet and 4 feet. The longer the level, the more accurate it will be at determining level across greater distances. Regular levels usually have one horizontal vial, but may also have additional vertical vials mounted on the side for plumbing vertical surfaces.

Common Uses of Regular Levels

– Checking level and plumb on walls, floors, countertops, appliances, furniture, etc.

– Leveling surfaces during tile installation, flooring, wall framing and more

– Establishing level baseline for projects using height rods and string lines

– Determining pitch and angle for ramps, drainage, work surfaces

– Leveling machinery, equipment, and other installations

What is a Torpedo Level?

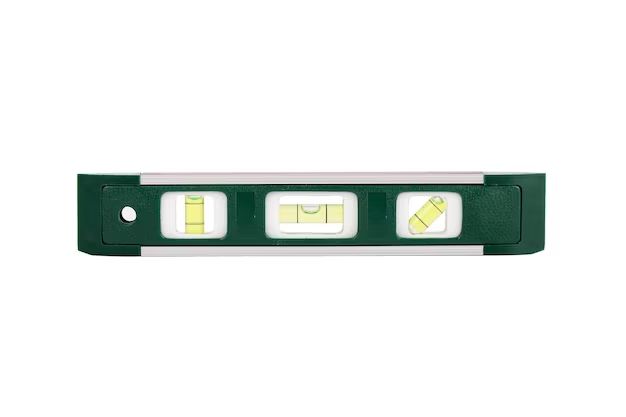

A torpedo level is a small, compact level designed for accessing confined spaces and leveling smaller projects. It gets its name from its elongated, torpedo-like shape. The body is rounded on the bottom to allow it to fit easily into tight spots and corners.

Torpedo levels contain the same basic internal vial(s) as a regular level. The main difference is their shorter body length, usually 6” to 12”. In addition to a horizontal vial, most torpedo levels also incorporate one or more vertical vials for plumbing objects along both axes.

The compact size makes torpedo levels extremely portable and convenient for basic leveling needs. However, their short vials limit their overall accuracy compared to longer spirit levels.

Common Uses of Torpedo Levels

– Basic leveling and plumbing for smaller jobs like hanging pictures, shelves, curtain rods, lighting fixtures, etc.

– Checking level and plumb on trim, molding, pipes, handrails, and other tight spaces

– Fine tuning adjustments on appliances, machinery, instruments

– Measuring angles and pitch in awkward areas

– Fitting into tool belts and pockets for easy accessibility

Key Differences

Length

The most obvious difference between regular and torpedo levels is their length. Regular levels are long, ranging from 9 inches to 5 feet or more. This gives them better accuracy across greater distances. Torpedo levels max out around 1 foot in length, limiting their scope but improving portability.

Shape

Regular levels have a flat straight shape with square edges. This allows their wide bases to sit flush on surfaces. Torpedo levels have a rounded, tube-like shape with a narrow profile. This shape improves maneuverability in tight spaces.

Vials

Both types of levels use vials to gauge level planes, but the arrangement differs. Regular levels typically have at least one large horizontal vial. Torpedo levels have a horizontal vial plus one or more vertical vials in a compact configuration.

Weight

Regular levels are larger and heavier, with more substantial frames. Torpedo levels weigh only a few ounces, making them ultra-portable.

Accuracy

The longer the vial, the more accurate the readings. Regular levels with long vials can level across great distances down to 1/16th of an inch. Torpedo vials max out around 6-12 inches, limiting accuracy to about 1/8th of an inch.

Price

Good regular levels cost $40 to $200. Torpedo levels range from $5 to $40.

Applications

Regular levels are better for long surfaces, level baselines, precision work, and commercial construction. Torpedo levels are ideal for everyday household jobs, tight spots, rough work, and basic leveling needs.

When to Use Each Type

Use a Regular Level When:

– Leveling across long surfaces like floor joists, countertops, wall framing, etc.

– Establishing level lines for large projects using height rods

– Precision leveling is required within 1/16th inch or less

– Checking elevation, pitch, and angle over long distances

– Leveling commercial work like machinery, equipment, metalworking, etc.

– Accessing the surface with a long tool is feasible

Use a Torpedo Level When:

– Working in very tight, confined spaces

– Leveling small surfaces under 1 foot

– Portability and easy access are key

– Precision requirements are less strict (within 1/8 inch is often adequate)

– Working on household projects like hanging pictures, shelves, tiles, etc.

– The surface cannot be accessed with larger tools

Pros and Cons Comparison

| Level Type | Regular | Torpedo |

|---|---|---|

| Length | Long (2′ to 5+’) | Short (6″ to 1′) |

| Shape | Flat and straight | Rounded and tube-like |

| Vials | Typically 1 horizontal | 1+ horizontal, 1+ vertical |

| Weight | Heavier | Very light |

| Accuracy | Highest accuracy | Moderate accuracy |

| Price | $40 to $200 | $5 to $40 |

| Applications | Large, long surfaces. Precision work. | Tight spaces. Basic household jobs. |

| Pros | Greater accuracy over distance. Robust for heavy use. | Compact size. Maneuverable. Portable. |

| Cons | Bulky. Difficult to fit in tight spots. | Limited accuracy. Not suitable for precision leveling. |

Conclusion

In summary, regular and torpedo levels serve similar purposes but have distinct designs suited for different use cases. Regular levels are the go-to for carpentry, construction, machinery and any application needing reliable accuracy across long surfaces. Their potential downside is lack of maneuverability in tight areas.

Torpedo levels are designed for accessibility and convenience, trading off some precision for compact size. They excel at basic household jobs, rough work, and getting into cramped areas where regular levels don’t fit. But they lack the fine accuracy needed for finish work and commercial installations.

Choosing between these two common types of levels depends largely on the specifics of the project. Having both in your toolkit gives you flexibility to handle leveling tasks in any situation. And their low cost makes owning one or several of each quite affordable, even for casual DIYers. With a little practice and experience, regular and torpedo levels can make almost any project go just a little smoother.

Additional Facts and Data

History of Levels

– Earliest levels date back to ancient Egypt, using water in a trough to gauge level planes

– Romans, Greeks advanced leveling, used channels, aqueducts, drains requiring precise gradients

– Early spirit levels had alcohol and lamp black vials, originating ~1663

– Modern spirit vial design patented in 1896, popularized in early 20th century

– Torpedo levels emerged mid-20th century for ease of use in tight spaces

Level Materials and Manufacturing

Common level frame materials:

– Aluminum – Lightweight but durable, popular in torpedo levels

– Acrylic – Optically clear viewing windows

– Wood – Attractive though less durable than metals

– Magnesium – Excellent strength-to-weight ratio

Vial fluid ingredients:

– Ether – Clear, stable, fast response time

– Colored alcohol – Enhances bubble visibility

– Mineral oil – Freezes at very low temperatures

– Vegetable oil – Environmentally friendly

Level vial markings:

– Etched or printed scales in fractions of an inch or degrees of angle

– Installation guides for common applications like outlets or picture frames

– Colored bands marking level or plumb orientations

Manufacturing processes:

– CNC machines mill level channels in frames with precision

– Automated assembly lines insert vials, markings, components

– Waterproofing seals frame openings holding vials

– Laser calibration aligns vials perfectly perpendicular

Specialized Level Types and Uses

Post level – Attaches to vertical poles for plumbing and alignment

Line laser level – Projects a laser line across large areas

Rotary laser level – Spins laser in 360° plane for grading, excavating

Optical level – Precise leveling with telescope and height rod

Digital/smart level – Battery powered with digital displays and readings

Graduated rod level – Cut into precise measurements for level transfer

Carpenter’s level – Multi-surface custom fit for framing, construction

Mason’s level – Heavy duty for bricklaying and block foundations

Machinist’s level – Ultra precise, calibrated for machine work and metals

Level Techniques and Best Practices

– Verify vials are properly calibrated before each use

– Start by confirming floor or surface is approximately level

– Set level firmly against surface and hold until bubble settles

– Adjust surface rather than move level when bubble is off-center

– Take readings at multiple positions, especially on longer surfaces

– For critical projects, double check with a second level for accuracy

– Protect levels from damage by avoiding drops or shocks

– Clean vials gently using soft cloth, no chemicals or abrasives

– Store levels protected in cases when not in use

Safety Tips When Using Levels

– Wear proper protective gear like gloves, boots, goggles, hardhat

– Be cautious of pinch points when adjusting equipment or machinery

– Maintain awareness of electrical, gas lines hidden behind walls and floors

– Brace ladders or scaffolding firmly when leveling elevated surfaces

– Lift properly when handling heavy materials, avoid back strain

– Stop leveling and rest if experiencing fatigue or discomfort

– Use extreme care when leveling on uneven or unstable terrain

– Work in pairs for any hazardous leveling situations

Leveling Projects for Home DIYers

Basic Household Uses

– Hanging decor like pictures, shelves, mirrors and wall art

– Installing molding, trim work and cabinets

– Laying flooring like tile, laminate or hardwood

– Mounting TVs, speakers or other electronics

– Leveling appliances and fixtures like overhead lighting

– Adjusting doors and windows that are out of square

Outdoor/Landscaping Leveling

– Leveling stones, bricks for patios, walkways, retaining walls

– Establishing drainage grades and angles

– Setting fence posts and deck piers evenly

– Aligning landscaping features like flower beds

– Creating flat areas for shed foundations

– Leveling uneven ground for play areas, sport courts

Furniture Building and Repair

– Ensuring tabletops, chair seats, benches are level

– Leveling dresser, desk, or shelf units and drawers

– Keeping picture frames, mirrors, art even on walls

– Checking for sagging or warped surfaces needing shims

– Identifying wobbly furniture legs needing adjustment