DRYLOK and Drylok Extreme are both masonry waterproofing paints made by United Gilsonite Laboratories (UGL). They can be used to waterproof interior or exterior, above or below grade masonry walls and floors. Both products penetrate deep into pores of masonry to form a protective barrier that is resistant to water. However, there are some key differences between standard DRYLOK and Drylok Extreme that are important to understand when choosing the best product for your waterproofing project.

Page Contents

Main Differences

Here is a quick overview of the main differences between DRYLOK and Drylok Extreme:

- DRYLOK is a lighter-duty product meant for lower hydrostatic pressure situations.

- Drylok Extreme provides more heavy-duty waterproofing for higher hydrostatic pressure.

- DRYLOK requires 2 coats, while 1 thick coat of Drylok Extreme is usually sufficient.

- Drylok Extreme has higher solids content and thicker application.

- Drylok Extreme can bridge non-structural cracks up to 1/8″ wide.

- DRYLOK comes in white and custom tint bases, Drylok Extreme is only available in gray.

We’ll go into more detail on each of these key differences below. Understanding them will help you pick the right product for your specific waterproofing needs.

Intended Use and Performance

The main difference between DRYLOK and Drylok Extreme comes down to their intended level of waterproofing performance.

DRYLOK is a lighter-duty masonry waterproofer meant for water seepage situations with lower hydrostatic pressure. It forms a water-resistant barrier that helps prevent moisture passage through exterior or interior above-grade walls. DRYLOK can also be used for some below-grade foundation walls that experience minor dampness and seepage without extreme hydrostatic pressure.

Drylok Extreme is a high-performance waterproofing paint designed to withstand heavy water pressure. It can waterproof foundations with up to 10 psi of hydrostatic pressure from exterior groundwater and moisture. Drylok Extreme provides more complete waterproofing and vapor barrier protection compared to standard DRYLOK. It is meant for below-grade foundation walls that experience substantial hydrostatic pressure and flooding.

So in summary:

- DRYLOK is designed for above-grade applications or foundations with minor seepage.

- Drylok Extreme should be used for foundations with heavy hydrostatic pressure and flooding.

Choose Drylok Extreme if you need true waterproofing rather than just a water-resistant coating. But DRYLOK will work fine for less demanding applications.

Coats Required

DRYLOK requires two coats applied at 50-100 sq.ft. per gallon per coat. Two coats are needed to achieve a complete waterproofing barrier.

Drylok Extreme is engineered to effectively waterproof with just one coat applied at 50-75 sq.ft. per gallon. The thicker single coat saves time and labor compared to applying two standard coats.

So in most cases:

- DRYLOK requires two separate coating applications.

- Drylok Extreme only requires one thick coating application.

Solids Content and Thickness

One reason Drylok Extreme can waterproof with one coat is its higher solids content and thickness.

DRYLOK has a solids content by volume of 46%. It dries to a thin coating of around 6 mils thick.

Drylok Extreme has a solids content of 60% by volume. It applies thicker at 10-12 mils in a single coat.

The thicker coating provides more complete waterproofing with fewer potential gaps or voids in the coating. It better withstands hydrostatic pressure.

Crack Bridging Ability

Another advantage of Drylok Extreme’s thicker application is improved crack bridging ability.

Drylok Extreme can bridge non-moving cracks up to 1/8″ width in concrete or masonry walls. The thick coating helps span across cracks to maintain the waterproof membrane.

Standard DRYLOK does not have significant crack bridging ability. Any cracks wider than a hairline must be patched before applying DRYLOK.

So Drylok Extreme offers another useful advantage for waterproofing cracked foundations or walls.

Color Options

DRYLOK comes in a white base that can be left white or tinted to custom colors. Tint bases like deep, clear, and neutral are also available for tinting with universal colorants.

Drylok Extreme only comes in a light gray base color. It cannot be tinted to custom colors.

So DRYLOK offers more finish options if you need to match a specific color scheme. Drylok Extreme can only be used if a gray waterproofing coating is acceptable.

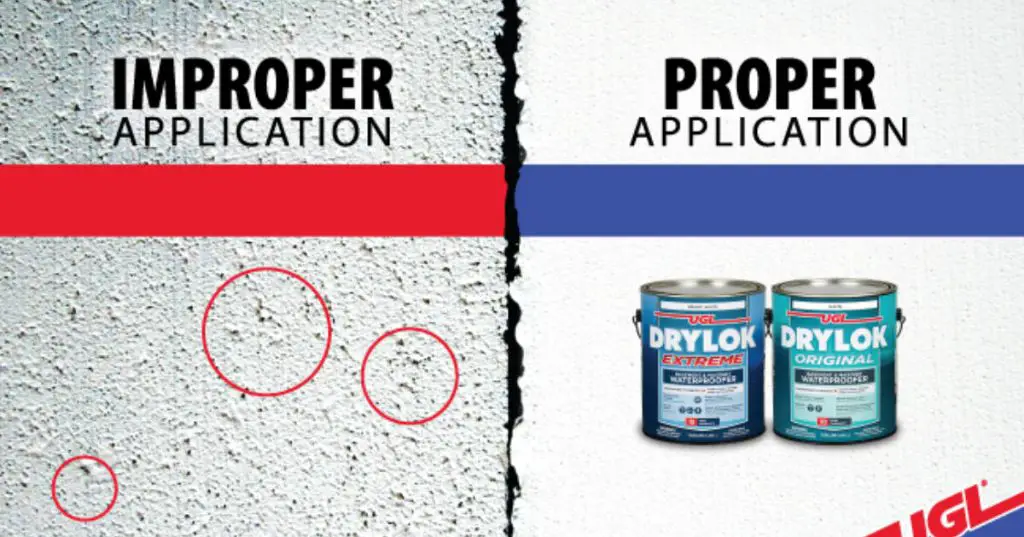

Application Surface Prep

Proper surface preparation is crucial when applying any masonry waterproofer like DRYLOK or Drylok Extreme. The surface must be:

- Clean – Remove any dirt, oils, efflorescence, salts, or other contaminants

- Structurally sound – Repair any cracks, holes, loose surface material

- Dry – Allow new concrete or masonry to cure at least 28 days

DRYLOK and Drylok Extreme can both be applied to concrete, concrete block, brick, stucco, and cinder block. Surface alkalinity must be below pH 13 for proper adhesion. DRYLOK recommends pre-treating exceptionally dense or polished concrete with a diluted muriatic acid solution before application.

Be sure to follow all preparation guidelines from the manufacturer before applying either waterproofing paint. Proper prep helps ensure you achieve long-lasting waterproofing results.

Application Tips

Here are some helpful application tips for both DRYLOK and Drylok Extreme:

- Apply when temperatures are between 50-90°F

- Use a 3/4″ nap roller or suitable spray equipment

- Work coating into the surface, especially on porous masonry

- Only apply to unfrozen, frost-free surfaces

- Back-roll after spraying to fill in gaps

- Allow 2-3 hours between coats of DRYLOK

- Allow full 7 day cure before exposing to water pressure

Following the manufacturer’s application instructions is also critical. Taking shortcuts can lead to failure or reduced waterproofing capability.

Cost Comparison

In terms of cost, Drylok Extreme is more expensive than standard DRYLOK per gallon. However, keep in mind Drylok Extreme will cover more area per coat.

Here are some example cost estimates:

- DRYLOK: $30-50 per gallon

- Drylok Extreme: $70-90 per gallon

But a single coat of Drylok Extreme at 50-75 sq.ft. per gallon may actually be less expensive overall than applying two coats of DRYLOK at 100 sq.ft. combined coverage.

The best value depends on the specifics of your project area and required number of coats.

Limitations

DRYLOK and Drylok Extreme do have some limitations to be aware of:

- Not meant for below-grade exterior foundation walls (Use UGL foundation coatings instead)

- Cannot bridge or fill moving cracks – these must be repaired

- Only for vertical, above-grade applications

- Not for use under hydrostatic pressure exceeding product ratings

- Not for immersed environments like pools, tanks, etc.

Always read the full technical data sheet and instructions before using these masonry waterproofing paints. Follow all listed limitations and application guidelines.

Conclusion

Drylok Extreme offers more robust waterproofing performance compared to standard DRYLOK. It can withstand heavy hydrostatic pressure from 10 psi. A thick single coat seals foundation walls and resists moisture.

DRYLOK is meant for lighter seepage protection for above grade walls. It requires two thin coats to waterproof.

Consider Drylok Extreme for basement foundations exposed to substantial exterior groundwater. Use DRYLOK for simpler seepage protection on above-grade walls or areas with minor dampness.

Be sure to prep surfaces properly and apply per instructions. Limitations must also be carefully followed. Talk to a UGL representative if you need help choosing the best product for your specific waterproofing application and requirements.