Foam products like Froth-Pak 620 and 650 are commonly used for insulating and air sealing applications. Both can help improve a building’s energy efficiency, but there are some key differences between the two to consider when deciding which to use.

Page Contents

Background on Froth-Pak

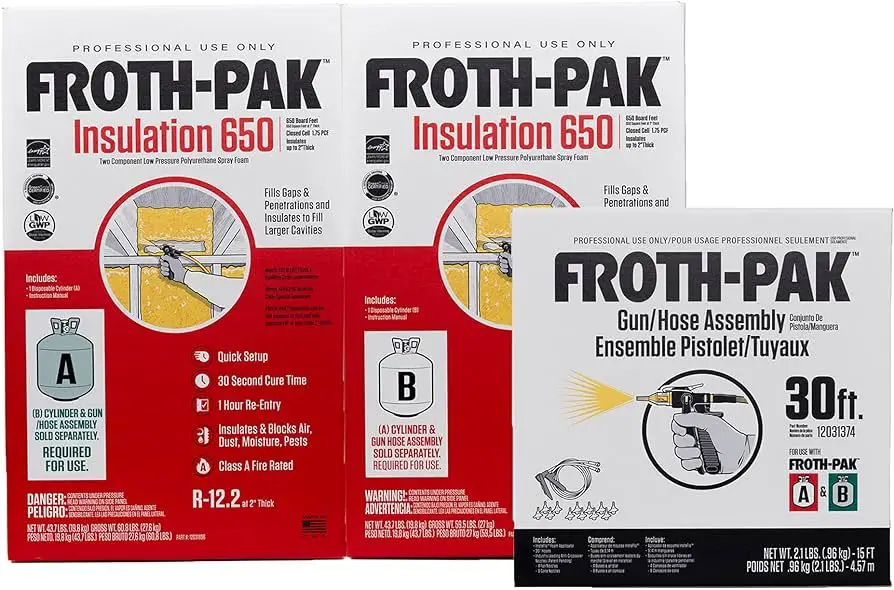

Froth-Pak is a type of spray polyurethane foam (SPF) made by Dow Chemical Company. It comes in portable, pressurized canisters that contain the foam components. When sprayed, the chemicals react and expand, forming rigid foam plastic insulation.

Froth-Pak is available in different formulations optimized for specific applications:

- Froth-Pak 120 is a 1.75 pound foam for craft and art projects

- Froth-Pak 200 is a general insulating foam

- Froth-Pak 620 is an insulating foam for exterior applications

- Froth-Pak 650 is an insulating foam designed for interior applications

Key Differences Between Froth-Pak 620 and 650

While both 620 and 650 can be used to insulate buildings, there are some notable ways in which the two formulations differ:

Intended Use

Froth-Pak 620 is designed for exterior use, while 650 is made for interior applications. The main reason for this difference is that 620 has enhanced moisture resistance and durability for outdoor exposure.

R-value

R-value indicates an insulation’s ability to resist heat flow. The higher the R-value, the better its insulating performance. Froth-Pak 620 has an R-value of 5.8 per inch, while 650 has a slightly higher value of 6.3 per inch.

Density

Froth-Pak 620 cures to a density of around 2 pounds per cubic foot (pcf). 650 is denser at 2.5 pcf. The higher density makes it more rigid and robust for interior spaces.

Fire Rating

When cured, both 620 and 650 have a flame spread index of 25 or less, meeting code requirements. However, 650 has a lower smoke developed index. This makes it more ideal for interior spaces where smoke density in a fire is a concern.

VOC Emissions

650 complies with stringent California Department of Public Health (CDPH) VOC emission standards for indoor foam products. 620 has higher VOC emissions, making 650 a better choice for indoor air quality.

Cure Time

Froth-Pak 650 cures more slowly than 620. Full cure can take 1-2 hours for 650, while 620 cures in about 30 minutes. The slower cure is preferable for interior applications where precision and finish quality are important.

Cost Comparison

In general, Froth-Pak 620 and 650 cost about the same per board foot. However, price can vary by distributor. Some factors impacting cost:

- Size of kits – Larger kit sizes often have lower per unit cost

- Volume discounts – Purchasing multiple kits may provide a discounted rate

- Shipping fees – Products shipped direct from manufacturer vs distributor inventory

Typical kit sizes and prices:

| Product | Kit Size | Price Range |

|---|---|---|

| Froth-Pak 620 | 200-board-foot kit | $300 – $350 |

| Froth-Pak 620 | 600-board-foot kit | $800 – $900 |

| Froth-Pak 650 | 200-board-foot kit | $325 – $375 |

| Froth-Pak 650 | 600-board-foot kit | $850 – $950 |

Conclusion

In summary, the main differences between Froth-Pak 620 and 650 are:

- 620 is designed for exterior use, while 650 is formulated for interior applications

- 650 has slightly higher R-value and density than 620

- 650 meets strict standards for fire rating and VOC emissions

- 650 cures more slowly than 620

While both can provide effective insulation and air sealing, choosing the product designed specifically for your project’s location and needs will provide optimal performance.