Determining the electrical load for a building or home is an important part of the design and construction process. The electrical load determines the capacity and ratings for electrical equipment, wiring, and circuits. An accurate load calculation helps ensure that the electrical system can meet the needs of the building without being overloaded.

Page Contents

- 1 What is electrical load?

- 2 Why calculate electrical load?

- 3 What factors determine electrical load?

- 4 Electrical load calculation methods

- 5 Basic residential load calculation

- 6 Basic commercial building load calculation

- 7 Factors for load estimation

- 8 Common electrical loads

- 9 Specialized load calculations

- 10 Software tools for load calculations

- 11 Conclusion

What is electrical load?

Electrical load refers to the amount of power (watts) needed to operate all electrical devices and equipment in a building. It represents the total demand for electricity for lighting, appliances, HVAC systems, electronics, machinery, and other items running on electricity.

Load calculations take into account three types of electrical loads:

- Continuous loads – Equipment and lighting that is likely to operate for long periods of time (over 3 hours), such as refrigerators, machines, and fluorescent lighting.

- Non-continuous loads – Equipment that is likely to operate intermittently, such as ovens, vacuum cleaners, power tools.

- Motor loads – The starting and running power requirements for electric motors, such as those used in HVAC equipment, elevators, and machinery.

Why calculate electrical load?

There are several important reasons to accurately calculate the anticipated electrical load for a building:

- To size the electrical service and components – The service entrance, wiring, circuit breakers/fuses, and conduits need to be sized to handle the expected load.

- To maintain voltage – Undersized electrical components can cause voltage drop issues.

- To avoid circuit overload – Each circuit must be sized for the load to prevent breaker tripping or fires from overheated wires.

- For safety and reliability – Improper load calculations can lead to power outages or even shock/electrocution hazards.

- To meet electrical code requirements – The National Electrical Code (NEC) mandates proper load calculations.

What factors determine electrical load?

The electrical load of a building depends on several factors:

- Type of occupancy – Residential, commercial, industrial etc.

- Size of the building – Total floor area.

- Number and types of electrical equipment and appliances.

- Lighting needs and design.

- HVAC system size and components.

- Any special high-load equipment like machinery or electric vehicle charging.

- Future expansion plans.

The trick is to calculate the maximum possible load during peak operating conditions. Safety factors are added in to account for unforeseen usage and future loads.

Electrical load calculation methods

There are a few standardized methods commonly used to calculate electrical loads. The basic process is to estimate the wattage for each item that will be powered, then add them all together for the total load.

1. Appliance Load Calculation

This method involves creating an itemized list of all electrical appliances, equipment, and lights. The voltage and wattage or amperage nameplate ratings are used to determine the estimated power draw for each item. These fixture loads are added together for the estimated overall load.

2. NEC Standard Loads

As an alternative to listing every item, the National Electrical Code (NEC) provides standard estimated load allowances for typical residential and commercial occupancies. For example, the NEC allows 3000 VA (Volt-Amps) for general lighting and 1500 VA for small appliance circuits in a dwelling unit.

3. Unit Load Method

The unit load method utilizes standardized demand factors for different types of building areas. The load allowance is calculated based on square footage for each area type, such as:

- Office space: 1.5 VA/sq ft

- Retail sales: 3 VA/sq ft

- Restaurant dining area: 4 VA/sq ft

This allows quick estimation of the overall load based on the floor plan.

4. Full Detailed Method

For large or complex buildings, a thorough detailed calculation is performed based on equipment specifications and lighting designs. This provides the most accurate load estimate but also requires the most effort.

Basic residential load calculation

Here is an example of a simple load calculation for a house using the appliance load method:

| Item | Watts | Quantity | Load (Watts) |

| LED lights | 10 | 20 | 200 |

| Compact Fluorescent lights | 20 | 5 | 100 |

| Outdoor security lights | 100 | 2 | 200 |

| Living room outlets | 1500 | 1 | 1500 |

| Kitchen outlets | 1500 | 1 | 1500 |

| Bathroom outlets | 1000 | 2 | 2000 |

| Electric oven | 2400 | 1 | 2400 |

| Electric stove | 9000 | 1 | 9000 |

| Microwave | 1500 | 1 | 1500 |

| Refrigerator | 500 | 1 | 500 |

| Dishwasher | 1200 | 1 | 1200 |

| Washing machine | 500 | 1 | 500 |

| Clothes dryer | 3000 | 1 | 3000 |

| Ceiling fans | 100 | 5 | 500 |

| Televisions | 300 | 3 | 900 |

| Desktop computer | 300 | 1 | 300 |

| Window AC units | 1500 | 3 | 4500 |

| Total Load | 32,100 |

From this sample calculation, the total estimated electrical load for the house is 32,100 Watts or 32.1 Kilowatts. This load calculation does not account for potential future additions or safety factors.

Basic commercial building load calculation

For a commercial building, the unit load method provides a quick estimate based on floor area and type of occupancy. As an example, consider a 10,000 square foot office building:

| Area Type | Sq.Ft. | Unit Load | Load (VA) |

| Office space | 8,000 | 1.5 VA/sq.ft | 12,000 |

| Corridors | 1,000 | 1 VA/sq.ft | 1,000 |

| Restrooms | 500 | 1.5 VA/sq.ft | 750 |

| Mech/Elec rooms | 500 | 2 VA/sq.ft | 1,000 |

| Total Load | 10,000 | 14,750 |

For this 10,000 sq ft office building, the estimated total voltage load is 14,750 Volt-Amps or 14.75 kVA, assuming 208/120V 3-phase power. This provides an initial load estimate, though a more detailed calculation would be required for the electrical design.

Factors for load estimation

There are some other helpful factors and notes to consider when estimating electrical loads:

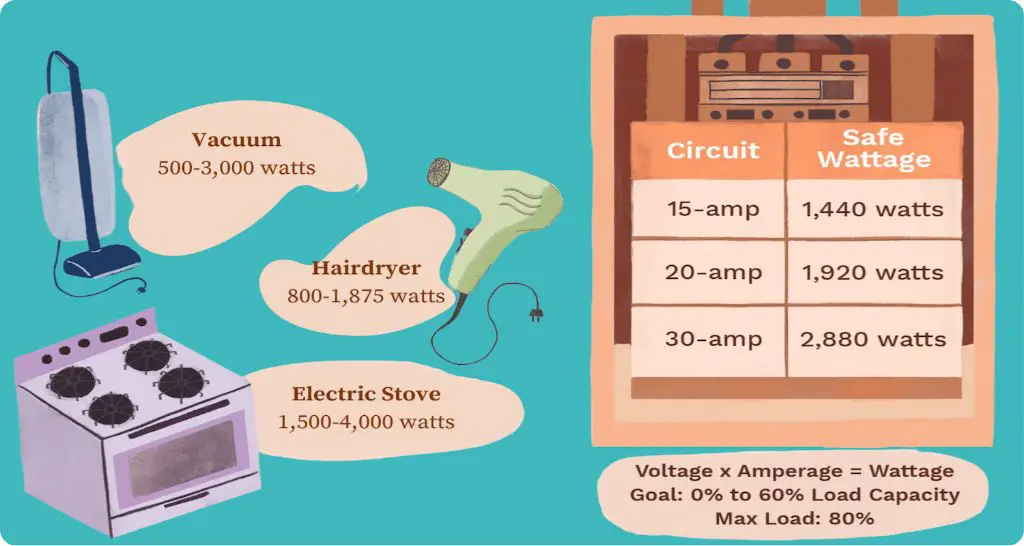

- Multiply Volts x Amps to get Watts (Power = Voltage x Current)

- Active power loads are stated in Watts (lighting, equipment)

- Reactive power loads are stated in Volt-Amps (motors)

- Load factor x Maximum load = Average load (for non-continuous loads)

- Demand factor x Total connected load = Estimated demand load

- Power factor must also be considered for motors, transformers, etc.

- Allow 25% extra capacity as a safety factor for unknown future loads.

- Break down lighting and receptacle circuits separately.

- Highest density areas need more circuits to limit loads per circuit.

Common electrical loads

Here are some typical load ratings to be aware of when estimating electrical loads:

Lighting Loads

- Incandescent light bulb: 60-100W

- LED light bulb: 6-12W

- Fluorescent tube: 20-40W

- HALO LED: 20-50W

- High bay HID: 250W

- Exit sign: 5-7W

Receptacle Loads

- General use receptacle: 180VA

- Microwave: 1500W

- Refrigerator: 500-800W

- Desktop computer: 120-500W

- Space heater: 1000-1500W

- Window AC: 1000-1500W

Motor Loads

- HVAC blower motor: 250W (1/3 HP)

- Large HVAC motor: 1500W (3 HP)

- Elevator motor: 10,000W (15 HP)

- Air compressor: 2000W (3 HP)

Common Area Loads

- Office lighting: 1-1.5 W/sqft

- Retail lighting: 1.5-2 W/sqft

- Industrial building: 2-2.5 W/sqft

- Supermarket: 20-30 W/sqft

- Restaurant dining: 4-5 W/sqft

- Hotel guest room: 400-600 VA

Specialized load calculations

Certain types of facilities require more extensive specialized load calculations. These include:

- Healthcare facilities – Critical electrical systems for patient care and safety systems require redundancy and high reliability.

- Data centers – Large UPS systems must provide continuous clean power for critical computer servers and equipment.

- Industrial facilities – Special calculations for large machinery loads including compressors, production lines, heavy equipment.

- Commercial kitchens – High-density cooking and refrigeration equipment require proper circuit distribution.

- Emergency systems – Life safety lighting, fire pumps, alarms, communications need dedicated backup power systems.

Specialized engineers conduct comprehensive calculations and modeling for these types of systems.

Software tools for load calculations

For larger buildings, engineers frequently use software tools to model and analyze the anticipated electrical loads. Some popular options include:

- eTools – Web-based load calculation with reporting. Easily models multiple scenarios.

- PowerCAD – Electrical design tool can generate circuiting and balanced loads.

- SKM Systems Analysis – Powerful modeling of large/complex electrical systems.

- ETAP – Simulate and monitor power systems with load flow analysis.

- Power Analytics – Web-based software for efficient modeling and compliance.

The proper software allows rapid scenario testing to optimize the building electrical design.

Conclusion

In summary, estimating electrical load requires determining the power demand in Watts for all equipment, appliances, motors, and lights that will operate in the building. This total load must be calculated as accurately as possible to size electrical service components and circuits properly. Common estimation methods include appliance loads, NEC standard loads, and unit area loads. Additional safety factors are applied for unknown future load growth. For complex buildings, specialized software provides analytical tools to precisely model anticipated usage and optimize the system design.