When it’s time to replace your vehicle’s struts, you’ll need to know what specific parts to get. Struts are an important part of your suspension system, so having the right components is crucial for performance, handling, and safety. In this comprehensive guide, we’ll go over everything you need to know about replacing struts, from the key components to the best practices for installation.

Page Contents

- 1 Strut Assembly Components

- 2 Strut Mounts/Bearings

- 3 nuts & bolts Replacement Sets

- 4 Coil Springs

- 5 Quick Strut Replacement Units

- 6 Strut & Spring Specs

- 7 Strut Installation Tips

- 8 Strut Replacement Costs

- 9 Symptoms of Bad Struts

- 10 Strut Vs. Shock – What’s the Difference?

- 11 Strut Vs. Coilover Suspension

- 12 Conclusion

Strut Assembly Components

A strut assembly has several main parts that work together to provide suspension, shock absorption, and stability. Here are the key components:

- Strut housing – The main structural component that connects the assembly to the vehicle’s suspension and frame.

- Spring – Provides cushioning and absorbs impacts from bumps and road irregularities.

- Shock absorber – Contains a piston and fluid that dampens spring oscillations for a smoother ride.

- Upper mount – Attaches the top of the strut to the vehicle chassis and allows pivoting.

- Lower mount – Secures the bottom of the strut to the steering knuckle/brake assembly.

- Dust boots – Protect internal strut components from dirt, moisture, and debris.

When doing a replacement, you’ll need to get a fully assembled strut designed specifically for your vehicle’s year, make and model. The assembly will come pre-loaded with springs calibrated for your vehicle weight and suspension design.

Strut Mounts/Bearings

The upper and lower strut mounts are also wear items that may need periodic replacement. Mounts provide a pivot point and absorb side loads from steering and suspension movement. Over time, the rubber and bearings can deteriorate.

Symptoms of worn mounts include steering wander, clunking noises over bumps, and excessive vehicle body lean in corners. If you notice these symptoms, consider replacing the mounts when you change the struts. The mounts are inexpensive parts that are easy to swap. It’s smart preventive maintenance.

nuts & bolts Replacement Sets

When doing a full strut replacement, it’s also a good idea to replace the mounting nuts and bolts. These fasteners experience a lot of stress and can become stretched or damaged during removal. A full fastener kit ensures you have high quality hardware to securely mount the new struts.

The kits are very affordable and include all the nuts, bolts, washers and small parts needed for a complete job. Some also have special anti-seize lubricant for the threads. This prevents the fasteners from becoming stuck or frozen. Investing in new mounting hardware provides cheap insurance against headaches later on.

Coil Springs

If you just need to replace sagging or broken coil springs, you can typically do so without replacing the entire strut assembly. However, there are some caveats:

- You’ll need a spring compressor tool to remove and install the springs safely.

- If the strut cartridge or mounts are worn, it likely makes sense to replace those as well.

- Only use brand-name springs that match your vehicle’s specifications.

Overall, springs are fairly affordable, so it’s often better to just replace the full strut assembly. This ensures you get perfectly matched components designed to work together. But if budget is a concern, individual springs remain a viable option.

Quick Strut Replacement Units

For some vehicles, you can purchase complete “quick strut replacement” units. These come pre-assembled with springs and strut mounts. Quick struts allow for fast installation since no spring compressor is required. They also require zero assembly.

However, quick struts are typically more expensive than buying a full strut assembly kit. And the one-size-fits-all spring may not match your vehicle’s stock specifications. This could affect ride quality and handling. Overall, quick struts offer convenience at a premium cost.

Strut & Spring Specs

When sourcing replacement strut assemblies and springs, make sure to get the proper specifications for your vehicle:

- Length/Height – Extended struts support lifted vehicles, while shorter units accommodate lowering kits.

- Coil spring type – Choose between standard, variable-rate, and progressive springs.

- Spring rate – Measured in the force (lbs) needed to compress the spring 1 inch. Matched to the vehicle weight and usage.

- Compressed height – Height of the spring when under full compression or load.

- Free height – Unloaded height of the spring.

- Outer diameter – Must match the strut housing size.

Using application-specific struts and springs ensures proper suspension geometry, ride quality, and performance. Check with manufacturers’ catalogs or original factory service manuals for your vehicle’s specifications.

Strut Installation Tips

When you’re ready to install the new struts, follow these best practices for safe and easy replacement:

- Use a spring compressor to unload factory springs before removal. Be cautious as compressed springs contain dangerous force.

- Inspect all suspension components while the struts are out. Look for signs of wear on ball joints, sway bar links, tie rods, etc.

- Clean the entire strut assembly housing to remove dirt, grease and debris before installation.

- Torque all nuts and bolts to factory specs using a calibrated torque wrench.

- Bounce the vehicle afterward to settle the suspension. Then recheck all fasteners.

- Have the wheels aligned to specifications so tire wear is even.

Taking the time to do a careful installation ensures the job is done right the first time. Your efforts will be rewarded with better ride quality, handling, and service life from the new components.

Strut Replacement Costs

For an average sedan, expect to pay around $200-$300 for a pair of front struts, and around $150 for rear struts. Per-strut prices typically range from:

| Component | Price Range |

|---|---|

| Front Quick-Strut Assembly | $120-$250 each |

| Rear Quick-Strut Assembly | $80-$180 each |

| Front Coil Springs | $60-$120 pair |

| Rear Coil Springs | $40-$100 pair |

| Mounting Hardware Kit | $15-$30 |

Labor costs are approximately $100-$200 for a basic four-wheel strut replacement at an auto repair shop. For DIYers able to do the work themselves, the potential savings are significant.

Symptoms of Bad Struts

Here are some common signs that your struts may be worn out and in need of replacement:

- Excessive bouncing and rocking over bumps

- Deep squeaking or knocking noises

- Visible fluid leaking from the strut housing

- Car pulls to one side under braking

- Lowered ride height; sagging suspension

- Reduced handling ability and slower steering response

- Uneven tire wear due to misalignment

If your struts are original equipment, they may be worn out anywhere from 50,000-100,000 miles depending on your driving conditions. Evaluating symptoms and being proactive with replacements can help prevent extensive suspension damage down the road.

Strut Vs. Shock – What’s the Difference?

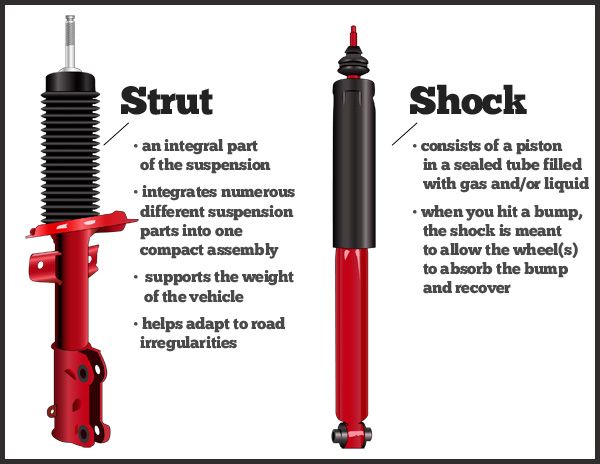

The terms “strut” and “shock” are sometimes used interchangeably when referring to certain suspension components. But there are some important differences:

- Struts – Integrated assembly with a shock absorber, coil spring, and mounting points all in one unit. Designed to support vehicle weight.

- Shocks – Only contains the damper unit itself. Works with separate springs to control bouncing and rebound.

So while shocks and struts perform similar roles, struts are a more complete, self-contained suspension component. They carry the vehicle load while also damping motion. In most modern cars, true struts have replaced shock absorbers for the front suspension.

Strut Vs. Coilover Suspension

Coilovers are an aftermarket upgrade that offers height adjustability and performance benefits over stock struts. Key differences include:

- Struts – Fixed ride height. Cannot be adjusted.

- Coilovers – Threaded spring perches allow ride height changes.

- Struts – Limited dampening adjustability on some models.

- Coilovers – Many have 30+ settings for compression/rebound tuning.

- Struts – Springs match OEM specs for comfort.

- Coilovers – Stiffer springs prioritize handling over comfort.

For lowered sports cars and track builds, coilovers offer significant advantages. But for regular passenger vehicles, factory-spec strut assemblies are often the best choice.

Conclusion

Understanding the components involved and having the right parts ready will help make your strut replacement go smoothly. Use this guide to select quality, application-specific assemblies and hardware tailored to your vehicle’s needs. With proper installation and alignment, your freshly replenished suspension will provide miles of solid performance, stability and comfort.