When installing a dryer vent, choosing the right size hole saw is important for proper ventilation. The vent size must match the dryer’s vent connector, which is typically 4 inches in diameter for electric dryers and gas dryers under 10 CFM exhaust flow. For high-efficiency gas dryers with over 10 CFM exhaust, a 5-inch vent is required.

Page Contents

Quick Answers

For standard electric and gas dryers: Use a 4-inch hole saw. This will match the 4-inch vent connector on the dryer.

For high-efficiency gas dryers over 10 CFM: Use a 5-inch hole saw. These dryers require a larger 5-inch vent.

For tight spaces: Consider a 3-1/4 inch hole saw. This allows use of a rigid metal vent with a slightly smaller diameter.

For venting through wood: Use a hole saw 1/8 to 1/4 inch larger than the vent. This allows space for easier vent installation.

Dryer Vent Size Guidelines

The main factors determining proper dryer vent size are:

– Dryer Type – Electric dryers require 4-inch vents, while gas dryers may need 4-inch or 5-inch.

– Exhaust Flow – Standard gas dryers under 10 CFM can use 4-inch, while above 10 CFM requires 5-inch.

– Vent Type – Rigid metal vents have slightly smaller diameters than flexible vents.

– Venting Path – Longer and tighter vent runs may need larger vents.

Following the manufacturer’s venting recommendations is always recommended. Consult the dryer user manual for the exact venting requirements.

Electric Dryers

Electric dryer vents should be 4 inches in diameter. This matches the size of the vent connector found on the back of most electric dryers.

Even though electric dryers have lower airflow than gas models, the lint and moisture exhausting through the system necessitates a full 4-inch vent. Reducing the vent size can lead to longer drying times and lint buildup.

Gas Dryers

Gas dryer vent size depends on the exhaust flow rating, which is measured in cubic feet per minute (CFM).

Standard gas dryers with up to 10 CFM exhaust flow can use a 4-inch vent. However, high-efficiency gas dryer models with over 10 CFM exhaust flow will require a 5-inch vent.

The increased airflow of high-efficiency gas dryers demands the larger 5-inch size to maintain proper ventilation. Check the manufacturer specs to determine the correct vent size.

Vent Installation Considerations

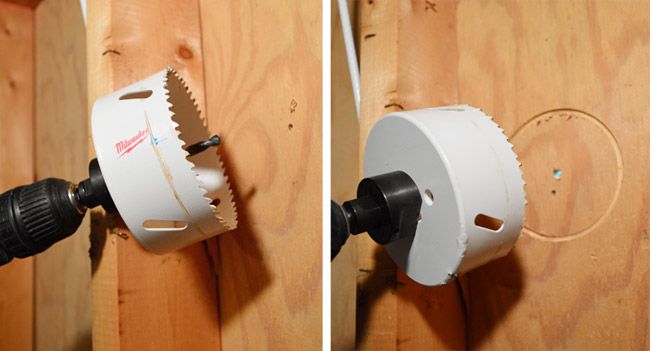

When selecting a hole saw for cutting vent holes, consider the following:

– For tight spaces, use a 3-1/4 inch hole saw. This allows using a slightly smaller rigid metal vent.

– For venting through wood, make the hole 1/8 – 1/4 inch larger than the vent diameter. This makes inserting the vent easier.

– Use hole saws designed for wood, metal, or masonry depending on the wall material.

– Follow fire code requirements for vent hole location on walls and roofs.

– Caulk around the vent exterior after installation to prevent moisture and pest intrusion.

Vent Diameter Reduction Concerns

It is not recommended to reduce the vent size below the dryer manufacturer’s specifications. Vent size reductions can lead to:

– Increased drying times – Smaller vents restrict airflow, reducing efficiency.

– Lint accumulation – Lint can build up and clog undersized vents over time.

– Moisture damage – Restricted airflow allows more moisture to condense in the vent, potentially causing mold, mildew and structural damage.

– Fire hazard – Excess lint trapped in the smaller vent is a fire hazard.

– Dryer damage – The dryer motor has to work harder with improper venting, leading to premature failure.

Only reduce the vent diameter if absolutely necessary in tight spaces and use the minimum reduction possible. Limit vent length to compensate for the restriction. Consider consulting a venting specialist before reducing vent size.

Vent Length Considerations

Longer vent runs require consideration of the following:

– Each 90 degree bend adds 5 feet of equivalent length. Avoid bends when possible.

– Keep total vent length under 35 feet where possible. Up to 100 feet is possible with proper sizing.

– Use rigid smooth-walled metal vent for longer lengths. This reduces resistance and lint buildup.

– Increase vent size by one inch for lengths over 35 feet. This compensates for the added airflow resistance.

– Reduce maximum vent length by 5 feet for each vent diameter reduction. Smaller vents have greater resistance.

– Slope the vent run downward towards the dryer at 1/4 inch per foot. This allows condensation drainage.

Proper planning of the vent routing during installation can optimize dryer performance and limit negative airflow effects.

Vent Material and Construction

The vent material and construction also impact airflow resistance and lint accumulation. Follow these best practices:

– Use rigid metal venting. The spirally reinforced metal offers optimal airflow and limits lint buildup inside.

– Ensure joints are oriented in the direction of airflow. Orienting the inner joint ridges correctly minimizes resistance.

– Seal all joints with aluminum tape or duct sealant. Air leaks allow lint escape and moisture damage in walls.

– Avoid flexible plastic or foil venting. The ridges and seams trap lint excessively, increasing fire risk.

– Install with a downward slope. A 1/4 inch per foot slope allows moisture drainage out the dryer.

Correct construction using proper vent materials is crucial for safety and optimal performance. Consult local building codes for any specific venting requirements.

Hole Saw Recommendations

Here are recommended standard size hole saws for cutting vent holes:

| Vent Size | Hole Saw Diameter |

| 4-inch round vent | 4-1/4 to 4-1/2 inches |

| 5-inch round vent | 5-1/4 to 5-1/2 inches |

| 3-1/4 inch round vent | 3-1/2 inches |

The 1/4 to 1/2 inch oversizing allows easier insertion of the vent pipe into the hole. It also provides space for sealant around the vent edges.

For specialty vents like wall terminals and rectangular vents, follow the manufacturer’s hole cutting recommendations.

And be sure to use hole saws appropriate for the material, such as wood-boring or masonry/tile specialty bits. Applying lubricating oil around the cutting edge can also improve hole saw performance.

Conclusion

Choosing the proper hole saw size for a dryer vent installation ensures the system will operate safely and efficiently. Matching the vent size to the dryer model’s specifications, accounting for exhaust flow ratings, and considering the length of the vent run all factor into selecting the right hole saw diameter for the job. With the proper hole cut, the vent can then provide adequate ventilation for a lifetime of clothes drying.