Pressure washers require o-rings to create tight seals and prevent leaks in high pressure applications. The size of o-ring used depends on the specific pressure washer model and component where it is installed. Here’s a quick overview of common o-ring sizes for various pressure washer parts.

Page Contents

Pump O-Rings

The pump is the heart of a pressure washer. It pressurizes the water flow to create the high pressure spray. Pump o-rings come in several common sizes:

- 1/8″ x 3/32″ – For seals on small pump plungers and shafts

- 3/32″ x 5/32″ – For seals between pump head and crankcase

- 1/4″ x 3/8″ – For pump head bolts and covers

- 3/8″ x 9/16″ – For seals on larger pump shafts

Using the correctly sized o-ring is critical for proper pump operation. Undersized o-rings can leak, while oversized rings can bind and cause friction. Matching the o-ring to the pump manufacturer’s specifications ensures good sealing and smooth operation.

Trigger Gun O-Rings

The trigger gun releases the pressurized water flow when the trigger is pulled. O-rings are used to seal the connections between trigger gun components.

- 1/8″ x 1/4″ – Seals trigger mechanism

- 1/4″ x 3/8″ – Seals handle to barrel connection

- 1/8″ x 3/16″ – Seals trigger pivot points

Regular lubrication of trigger gun o-rings helps maintain a tight seal and prevents sticking and wear over time.

Hose Fitting O-Rings

High pressure hoses connect the pump to the trigger gun. The hose fittings use o-rings to seal the connection points and prevent leaks.

- 1/4″ x 3/8″ – Seals gauge and nozzle hose connections

- 3/8″ x 1/2″ – Seals pump outlet hose connections

- 1/2″ x 5/8″ – For larger diameter high pressure hose fittings

Ensure hose fittings are properly tightened so o-rings remain compressed to maintain the high pressure seal.

Nozzle O-Rings

Nozzles focus the high pressure water into various spray patterns. O-rings are used internally in the nozzle components and to seal nozzle connections.

- 1/16″ x 1/8″ – Seals small internal check valves

- 1/8″ x 3/16″ – Seals adjusting collar and pivot points

- 3/16″ x 1/4″ – Seals nozzle to hose connection

Nozzle o-rings take a lot of wear from high velocity water flow. Inspect and replace worn o-rings regularly to maintain performance.

Unloader O-Rings

The unloader regulates pump pressure when the trigger gun is not engaged. Unloaders use o-rings to seal plungers, valves, and connections.

- 1/8″ x 3/32″ – Seals unloader plunger and guides

- 1/8″ x 1/4″ – Seals unloader valve stems

- 1/4″ x 3/8″ – Seals unloader body connections

Dirty or worn unloader o-rings can cause unstable pump pressure and cycling. Replace annually or whenever wear is noticed.

Chemical Injector O-Rings

Chemical injectors meter soap or other chemicals into the pressure washer flow. O-rings maintain seals in the injector to prevent leaks and pressure loss.

- 1/8″ x 1/4″ – Seals injector plungers and seals

- 1/4″ x 5/16″ – Seals injector body joints

- 5/16″ x 3/8″ – For hose connections to injector body

Chemical injector o-rings should be inspected frequently as chemical additives can degrade rubber over time.

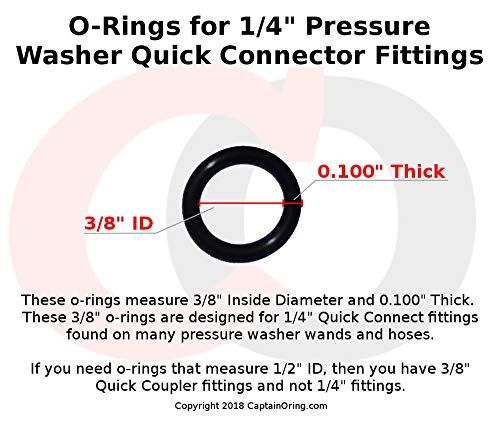

Quick Disconnect O-Rings

Quick disconnect fittings allow hoses and accessories to be conveniently connected without tools. The fittings use o-rings to seal and detach easily.

- 1/4″ x 3/8″ – Seals 3/8″ quick disconnects

- 3/8″ x 1/2″ – For 1/2″ quick disconnect fittings

- 1/2″ x 5/8″ – For 5/8″ quick disconnects

A light coat of silicone grease keeps quick disconnect o-rings flexible and ensures a tight seal.

Conclusion

Pressure washers rely on a range of o-ring sizes, typically in the 1/8″ to 3/8″ range, for sealing pump components, trigger guns, hoses, nozzles and accessories. Matching o-ring sizes precisely to the pressure washer manufacturer specifications ensures proper sealing and performance. Inspecting and replacing o-rings regularly is key to maximize pressure washer life and cleaning power.