Running a sub panel from your home’s main electrical panel to a detached garage or workshop is a common project for many DIYers. Having a sub panel in your garage allows you to safely add more circuits and outlets as needed, without overloading your main home panel. However, selecting the proper wire size is crucial for safety and performance.

Page Contents

- 1 How Much Power Will You Need?

- 2 Recommended Minimum Wire Size

- 3 Increase Wire Size for Long Runs

- 4 Choose an Insulated, Outdoor-Rated Cable

- 5 Determine Conductor Material Based on Environment

- 6 Protect Against Physical Damage

- 7 Use Proper Wire Burial Depth

- 8 Install a Dedicated Grounding Electrode

- 9 Include a Main Shutoff Disconnect

- 10 Follow Codes for Grounding and Bonding

- 11 Choose Appropriate Overcurrent Protection

- 12 Label All Circuits Clearly

- 13 Conclusion

How Much Power Will You Need?

The first step is calculating the total amperage that you’ll need in your garage sub panel. Here are some typical power demands to consider:

- Lighting circuits – estimate 1500 watts

- Outlets for tools – estimate total wattage of power tools used

- Major appliances like freezers or a mini-split AC unit – check nameplate for amp/wattage ratings

- Future demand – leave room for expansion by adding 20-30% more capacity

Add up the wattages and divide by 120 volts to calculate the total amps needed. It’s better to overestimate than undersize your sub panel amperage capacity.

Recommended Minimum Wire Size

The National Electrical Code (NEC) outlines the required capacities for feeder wires to sub panels, based on the circuit breaker size protecting the wire. Here are the recommended minimums:

| Sub Panel Main Breaker Size | Minimum Wire Size |

|---|---|

| 30 amps | 10 AWG copper |

| 40 amps | 8 AWG copper |

| 50 amps | 6 AWG copper |

| 60 amps | 6 AWG copper |

| 70 amps | 4 AWG copper |

| 100 amps | 2 AWG copper |

In most cases, a 60 amp sub panel fed with 6 AWG copper wire will provide sufficient capacity for a detached garage or workshop.

Increase Wire Size for Long Runs

The wire sizes in the table above are based on a maximum run of 75 feet from the main panel. For longer distances, you should increase the wire gauge to prevent voltage drop issues:

| Distance from Main Panel | Minimum Wire Size |

|---|---|

| 75-150 feet | Increase wire size by one gauge |

| 150-250 feet | Increase wire size by two gauges |

For example, if your sub panel is 100 feet from the house, use 4 AWG instead of 6 AWG copper wire.

Choose an Insulated, Outdoor-Rated Cable

For running wires underground between the house and garage, you should use an insulated, outdoor-rated cable such as:

- UF cable – Underground feeder cable with weatherproof insulation

- USE cable – Underground service entrance cable meets code for mains/sub panels

- THHN wires – Individual wires with THHN insulation in outdoor conduit

These are the proper cables designed to withstand both wet, underground conditions and the heat of carrying higher electrical loads safely.

Determine Conductor Material Based on Environment

For most residential feeder circuits, copper wiring is preferred as it has lower resistance and is less prone to corrosion. However, you can also use aluminum wire for runs over 50 feet as follows:

| Environment | Recommended Conductor |

|---|---|

| Damp or corrosive | Copper wire |

| Dry, non-corrosive | Aluminum wire |

When using aluminum, increase the wire size compared to copper. For example, for a 60 amp sub panel, use 4 AWG aluminum instead of 6 AWG copper.

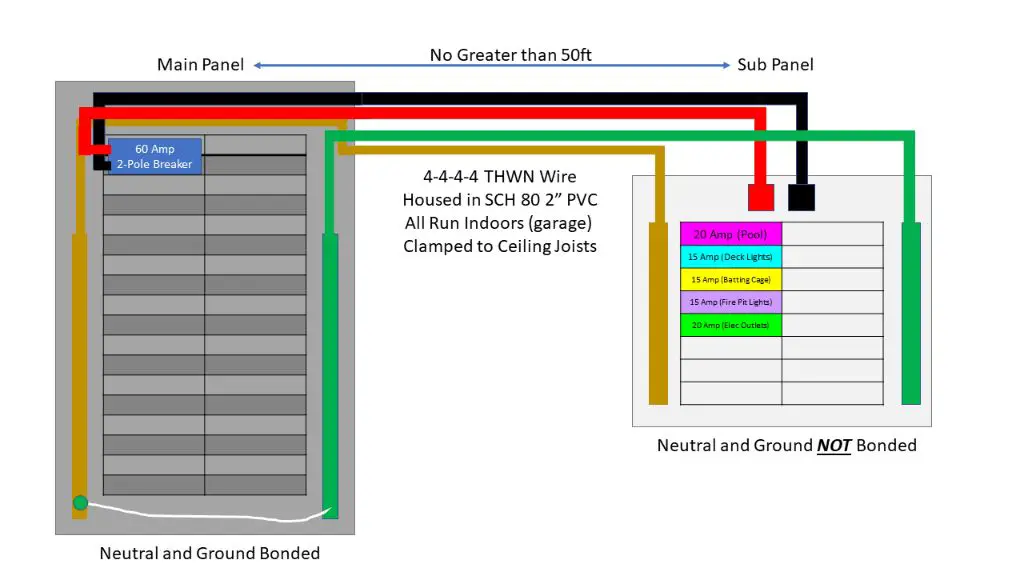

Protect Against Physical Damage

The feeder wires running between the house and garage should be protected against physical damage by running them through conduit. The main options are:

- PVC – Inexpensive plastic conduit that can be glued together

- Galvanized metal – More rigid steel conduit for maximum protection

- Direct burial – PVC conduits rated for direct underground installation

PVC and galvanized steel conduit provide extra protection where feeder wires are exposed or shallow buried. For deep burial, use Schedule 40 PVC conduit rated for direct burial.

Use Proper Wire Burial Depth

For running your sub panel feeder wires underground, proper burial depth is crucial:

- Direct burial cable – 24 inches underground

- In conduit – 12 inches underground

Burying wires at the proper depth avoids accidental digging and protects the insulation from temperature changes.

Install a Dedicated Grounding Electrode

The garage or workshop sub panel must have its own grounding electrode system, separate from the main house panel:

- Use one or more ground rods driven at least 8 feet into the earth

- Connect ground rod(s) to sub panel with 6 AWG copper ground wire

A properly installed grounding electrode ensures all circuits wired to the sub panel have a safe path back to earth in the event of a short circuit or overloaded neutral.

Include a Main Shutoff Disconnect

The sub panel should have a main shutoff disconnect that isolates it from the feeder wires back to the main house panel. This provides a way to safely shut power off to the detached building for maintenance.

Common options include:

- A main breaker at the top of the sub panel

- A separate disconnect switch near the sub panel

If using a separate disconnect, size it appropriately for the feeder wires – for example, a 60 amp switch for 6 AWG copper feeders.

Follow Codes for Grounding and Bonding

It’s crucial that you follow electrical code requirements for proper grounding and bonding in the sub panel:

- Install a separate equipment grounding conductor with feeders

- Bond neutral bus and case in sub panel

- Isolate neutral and ground buses from house panel

Proper grounding and bonding maintains safety and prevents voltage differences that can damage equipment.

Choose Appropriate Overcurrent Protection

The feeder wires, sub panel bus bars, and each circuit breaker in the sub panel must have properly rated overcurrent protection:

- Main breaker matches feeder ampacity

- Panel bus bars rated for main breaker size

- Breakers sized for connected circuit wire gauges

Overcurrent protection prevents overloaded wires from overheating and reduces fire hazards.

Label All Circuits Clearly

Finally, make sure you clearly label each circuit in the sub panel to avoid confusion. Indicate details like:

- Circuit number

- Area served (e.g. “Lights”)

- Wire gauge and overcurrent protection used

Accurate labeling will make future circuit identification and troubleshooting much simpler.

Conclusion

Installing a properly sized sub panel with suitable feeder wires and grounding will allow your garage or workshop addition to meet your power needs safely. Always obtain a permit and have the finished installation inspected to ensure you’ve met all electrical code requirements.