When loading a grease cartridge into a grease gun, it is crucial to orient it correctly so that the grease can flow properly during application. The opening of the cartridge must align with the mechanism inside the grease gun that pushes the grease out.

Page Contents

Quick Answer

A grease cartridge should be loaded with the plastic cap end going in first. The opposite end of the cartridge has a metal disc or plunger that needs to make contact with the pistol rod inside the grease gun barrel in order to push the grease out.

Grease Cartridge Orientation

A standard grease cartridge has a plastic cap on one end and a metal disc or plunger on the opposite end. The plastic cap covers the opening where the grease is dispensed from. This is the end that should be inserted into the grease gun first. The metal disc end needs to go in last so that it can make contact with the pistol rod.

When the metal disc end of the cartridge is lined up properly inside the grease gun barrel, the pistol rod can push against the disc to force grease out of the opening when you activate the grease gun.

Loading Step-by-Step

Follow these steps to load a grease cartridge correctly:

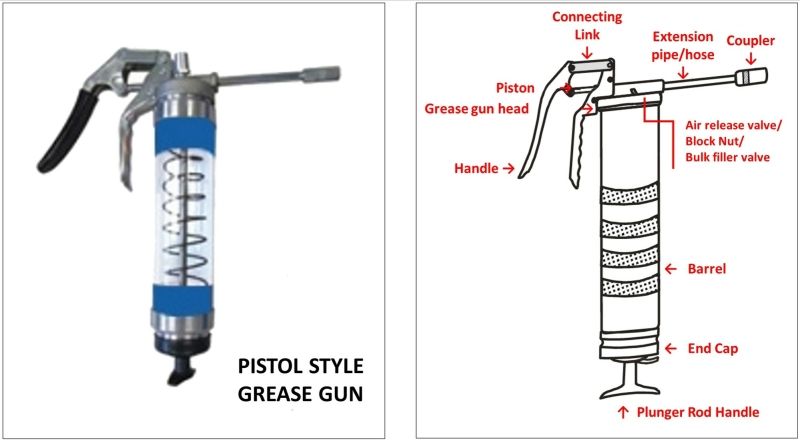

- Unscrew the barrel of the grease gun from the handle and set the handle aside.

- Remove any empty cartridges if present.

- Insert the new full cartridge with the plastic cap end going into the open barrel first.

- Push the cartridge all the way into the barrel so that just the metal disc is still showing.

- Screw the barrel back onto the grease gun handle.

- You should now be ready to pump and prime the grease gun before applying grease.

Why Cartridge Orientation Matters

Loading the grease cartridge incorrectly can prevent the grease gun from functioning properly. Here are some issues that can occur:

- The metal disc may get jammed into the opening of the cartridge if inserted first, sealing off the grease flow.

- The plastic cap end will not allow the piston rod to push against the metal disc to dispense grease.

- Grease may leak out around the cartridge if the cap end is not inserted fully into the sealed barrel.

Always taking a moment to orient the grease cartridge properly will ensure smooth grease flow and application. The plastic cap keeps the grease safely contained inside the cartridge until pressure is applied to the metal disc by the grease gun piston.

Typical Grease Gun Cartridge Styles

While most cartridges follow the standard plastic cap/metal disc design, there can be some variation in shapes and material:

- Flat disc – A flat, circular metal disc at one end.

- Cone disc – A cone-shaped disc that provides a pointed surface for the piston rod to press against.

- Foil seal – A foil covered opening instead of a plastic cap.

- Follower disc – A circular plastic follower that the piston presses into to dispense grease.

Regardless of the specific style, the basic rule is to insert the end with the covering or disc first, and the open grease dispensing end last.

Checking Used Cartridges

When changing out old used cartridges, you can quickly tell which end was inserted into the grease gun. The plastic cap or foil seal will still be in place on the end that was inserted first. You’ll be able to see the indented metal disc on the opposite end where the piston rod pressed against it.

Troubleshooting Cartridge Issues

If you experience any difficulty dispensing grease from a loaded cartridge, check these troubleshooting points:

- Make sure the cartridge is loaded properly with the plastic cap end inserted first.

- Inspect the barrel and piston rod for damage or blockages preventing movement.

- Ensure the cartridge is pressed fully into the barrel with the metal disc end visibly exposed.

- Try reloading the cartridge and re-priming the grease gun.

- Look for swollen or warped cartridges that may not fit properly in the barrel.

Catching and correcting any cartridge issues promptly can get your grease gun working again quickly.

Safety Tips

Keep these safety recommendations in mind when changing cartridges:

- Wear work gloves when handling spent cartridges to avoid contact with grease residue.

- Dispose of used cartridges properly according to local regulations.

- Ensure the grease gun is fully depressurized before attempting to reload it.

- Work in a clean area free of dirt and debris.

- Inspect new cartridges for damage before inserting into gun.

Conclusion

Always inserting the plastic capped or sealed end of a grease cartridge into a grease gun first will ensure proper orientation and hassle-free grease dispensing. Taking a moment to check both ends of a spent cartridge can also reveal which is the business end that attaches to the piston. Following good loading and maintenance practices will keep a grease gun running smoothly through many cartridge changes.